4 min read

Electron-beam Ruled Gratings for Future Ultraviolet/Optical Missions

Advanced semi-conductor fabrication methods will help improve the performance—and potentially reduce the cost—of the next major ultraviolet/optical space observatory.

The 2020 Astronomy and Astrophysics Decadal Survey recommended a successor to the beloved Hubble Space Telescope—a large observatory designed to study galaxies, stellar nurseries, supernovae, and hunt for a possible Earth twin. These science goals require this next-generation mission to be many times more powerful than Hubble, and to be sensitive to the ultraviolet light that traces key features of these phenomena. NASA’s Astrophysics Division has invested in several technologies to help enable this capability, including advanced diffraction gratings with higher efficiency and more creative design flexibility than the previous state of the art.

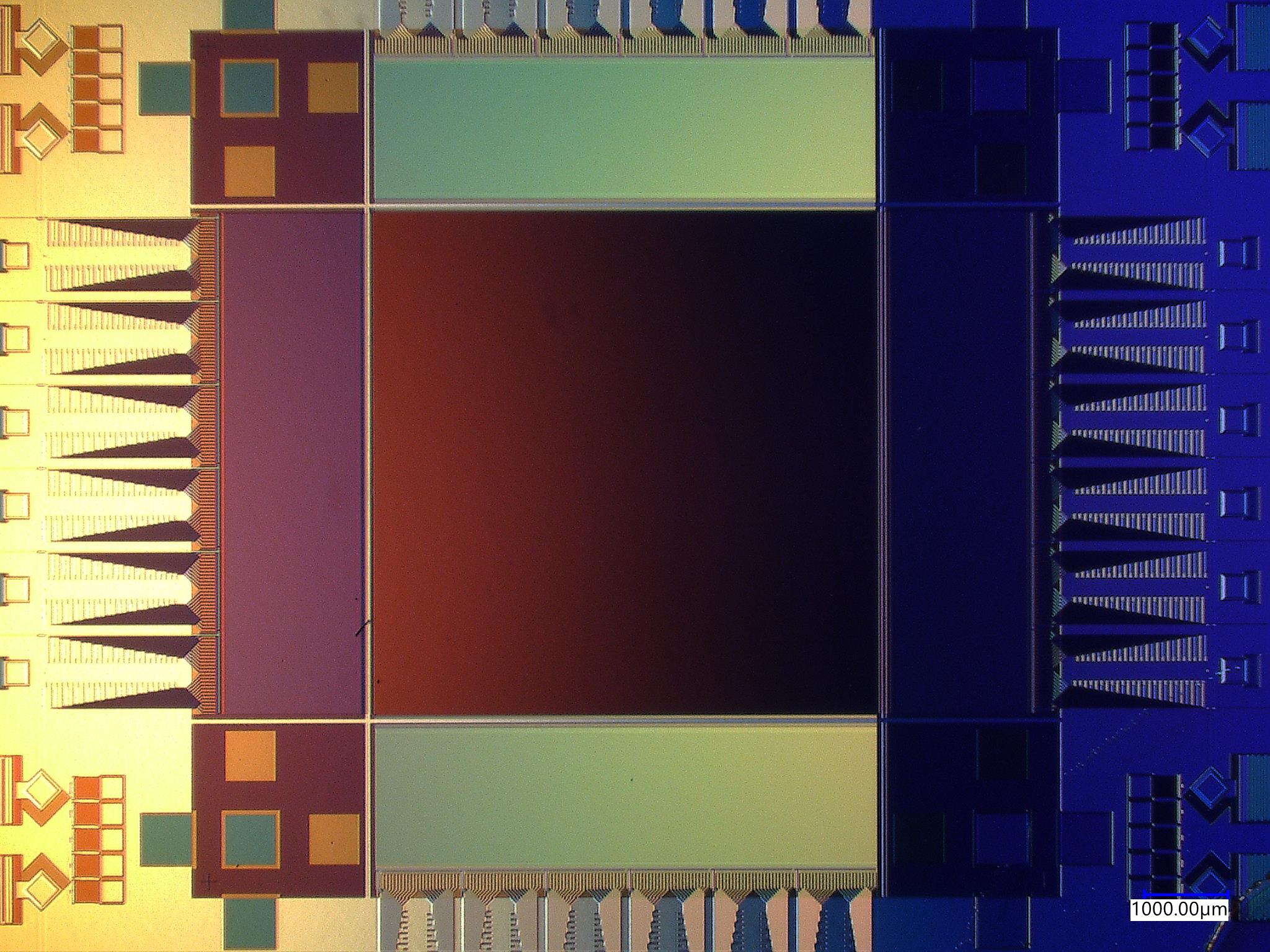

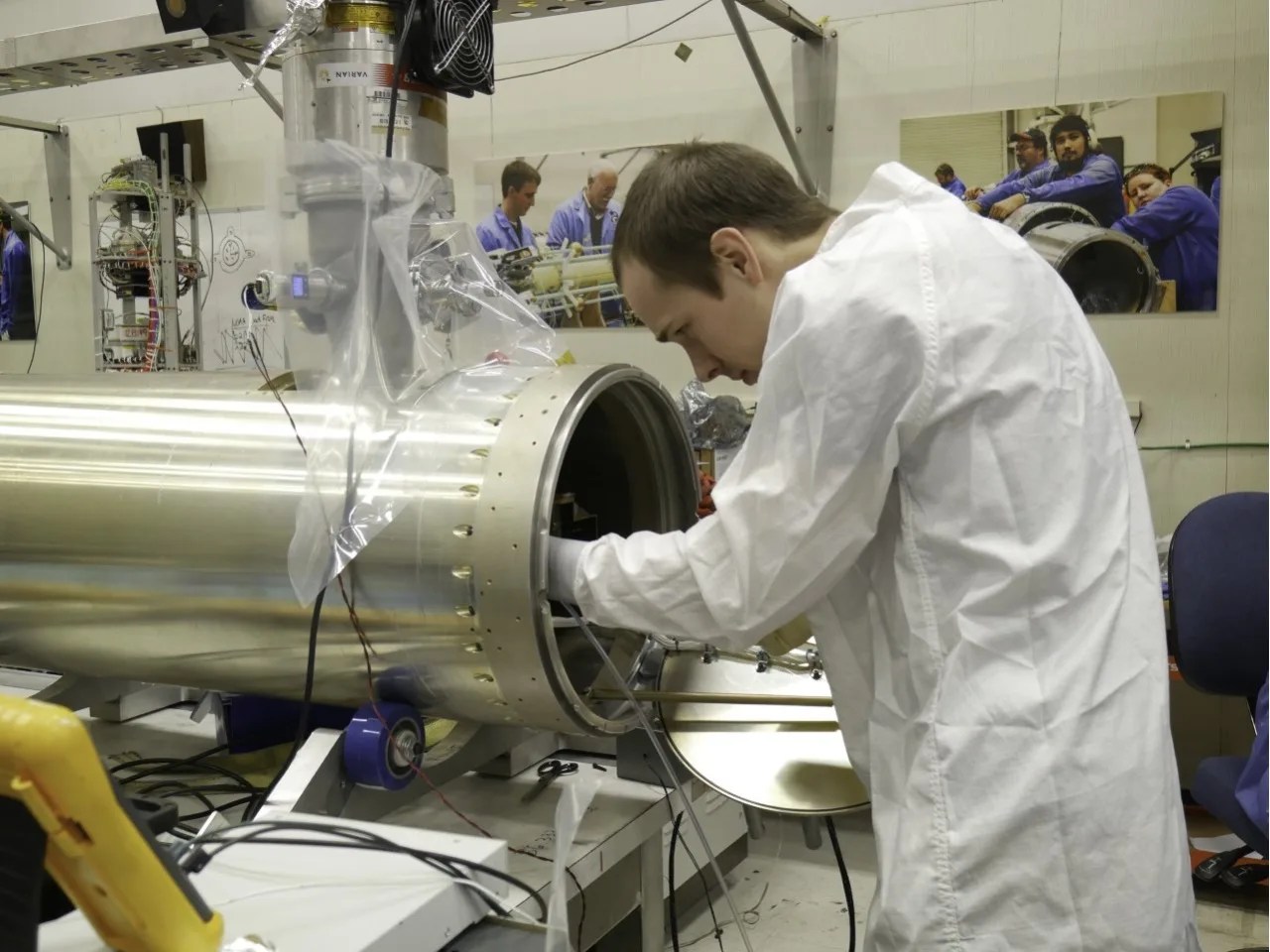

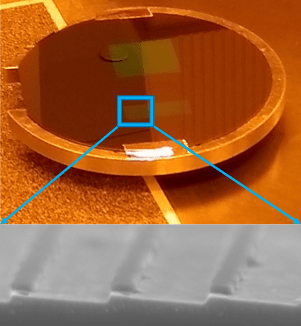

The technology behind these gratings was pioneered by Professor Randall McEntaffer at Pennsylvania State University (PSU). Professor McEntaffer, along with Dr. Fabien Grisé, then PSU graduate student Drew Miles, and the PSU nanofabrication laboratory staff used electron beam lithography and chemical etching techniques to rule X-ray gratings onto flat silicon wafers. By leveraging the crystal properties of the silicon, the resulting blazed grooves were exceptionally smooth, precise, and uniform across the grating surface.

NASA’s Strategic Astrophysics Technology (SAT) program has funded teams at the University of Colorado (CU) and Johns Hopkins University (JHU) in partnership with PSU to apply this grating fabrication technology to ultraviolet wavelengths. The team is focusing on improving conventional gratings employed on CU and JHU sounding rocket instruments, enabling a direct comparison with the state-of-the-art.

Echelle gratings, like those on Hubble’s Space Telescope Imaging Spectrograph (STIS), are low-period, high-blaze-angle gratings designed to operate at a steep angle of incidence. Echelle gratings enable high-resolution spectrographs that are commonly used to characterize chemical abundances in stars or, more recently, in exoplanet atmospheres. The SAT-sponsored team used the new technology to produce three etched silicon gratings that mimicked the characteristics of the gratings used on the Colorado High-resolution Echelle Stellar Spectrograph (CHESS), a sounding rocket instrument developed by Professor Kevin France at the CU Laboratory for Atmospheric and Space Physics (LASP). The new etched silicon gratings surpassed the diffraction efficiency of the CHESS flight echelle gratings by roughly 50%, and the far-ultraviolet echelle on STIS by nearly a factor of three, while also exhibiting less than one-sixth the scattered light when installed in the CHESS instrument.

These nanofabrication techniques also offer exciting opportunities to improve performance and enable new spectrograph designs that employ custom-shaped groove profiles. The electron beam tool has more flexibility for creating groove patterns than the conventional holographic techniques employed to develop Hubble’s Cosmic Origins Spectrograph gratings, and the new etching method enables a larger range of blaze angles.

The team is exploring this parameter space by using these etching techniques to develop gratings for the CU-LASP Suborbital Imaging Spectrograph for Transition region Irradiance from Nearby Exoplanet host stars (SISTINE) sounding rocket (PI: Kevin France) and the JHU Far-ultraviolet Off Rowland-circle Telescope for Imaging and Spectroscopy (FORTIS) sounding rocket (PI: Stephan McCandliss). These grating designs require both higher groove efficiency than gratings made with traditional holographic techniques (which equates to higher instrumental sensitivity), and more aberration control. If successful, this effort will demonstrate that gratings made with these new etching techniques could more than double the efficiency of the low-resolution, high-sensitivity modes on a future large observatory. The improved aberration control on the new gratings could also decrease instrument volume and mass by reducing the need for long optical pathlengths.

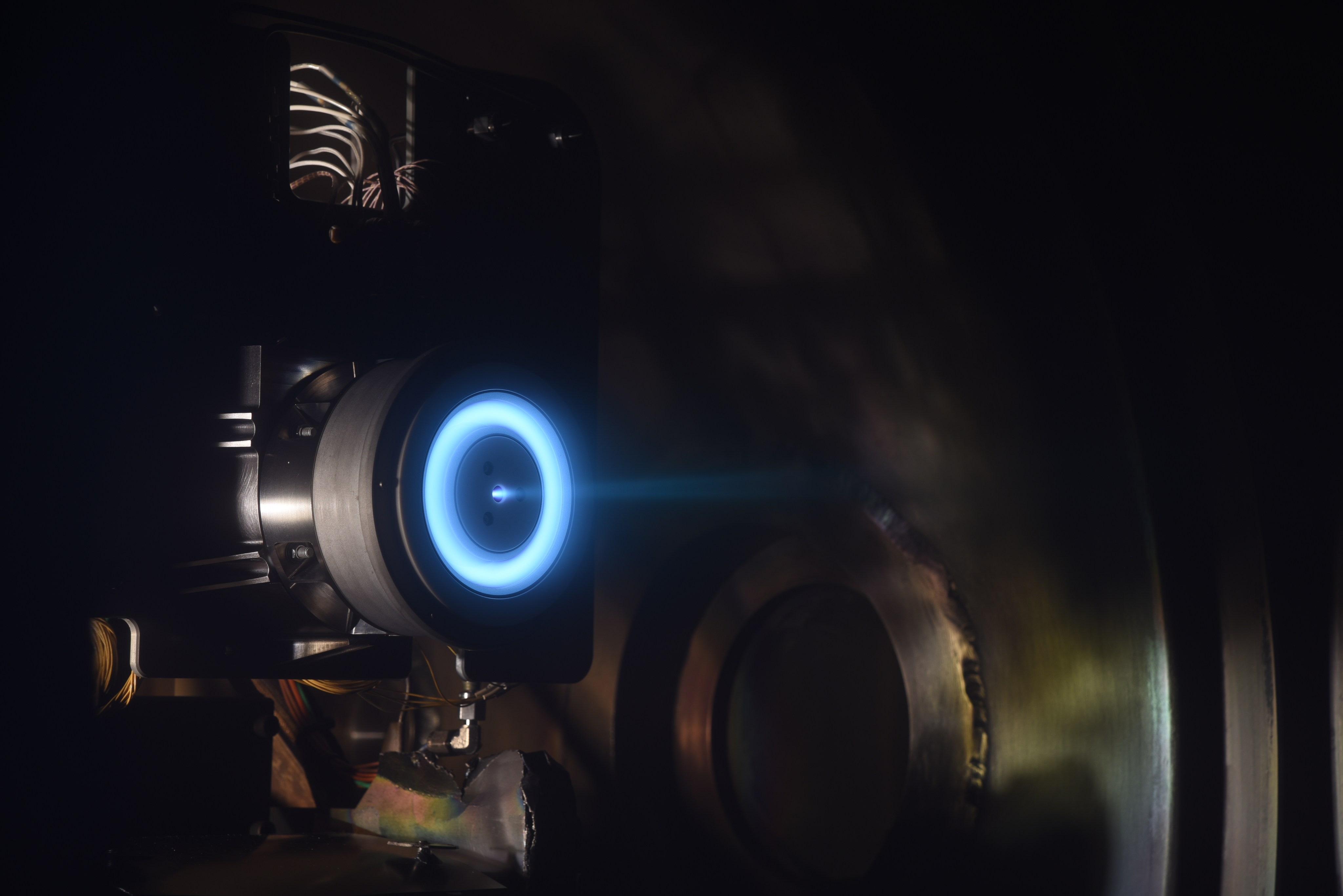

While the motivation for these gratings is driven by the prospect of a future large mission, the most immediate application of this new technology may be in small satellites or CubeSats, where the volume is especially limiting.

“This technology could really open up some new mission designs,” says CU-LASP Professor Brian Fleming, “Suddenly you can pack instruments with similar aberration control into tighter volumes, and maybe even use fewer optics. This can raise efficiency while reducing mass and volume, which for space missions often means lower cost.”

The project team is still working to successfully transfer curved, blazed profiles onto thick, powered optics. The team remains confident they will succeed in replicating the SISTINE and FORTIS gratings in the near future, and then plans to work toward flight testing of a new grating design to demonstrate readiness for future NASA missions.

Dr. Brian Fleming, University of Colorado Laboratory for Atmospheric and Space Physics (CU-LASP)

Astrophysics Division Strategic Astrophysics Technology Program. Some related work was funded under the NASA Explorer Program for the Extreme-ultraviolet Stellar Characterization for Atmospheric Physics and Evolution (ESCAPE) Small Explorer (SMEX) Phase A study.

Read more Technology Highlights