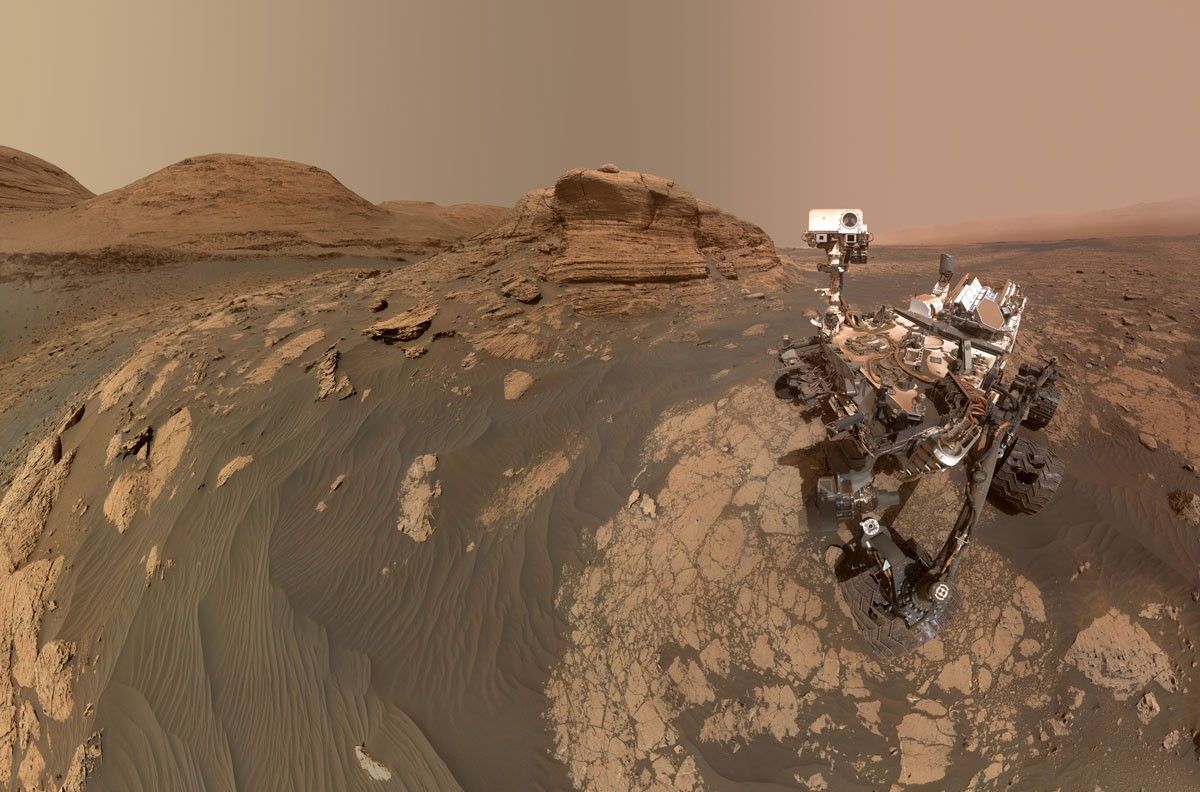

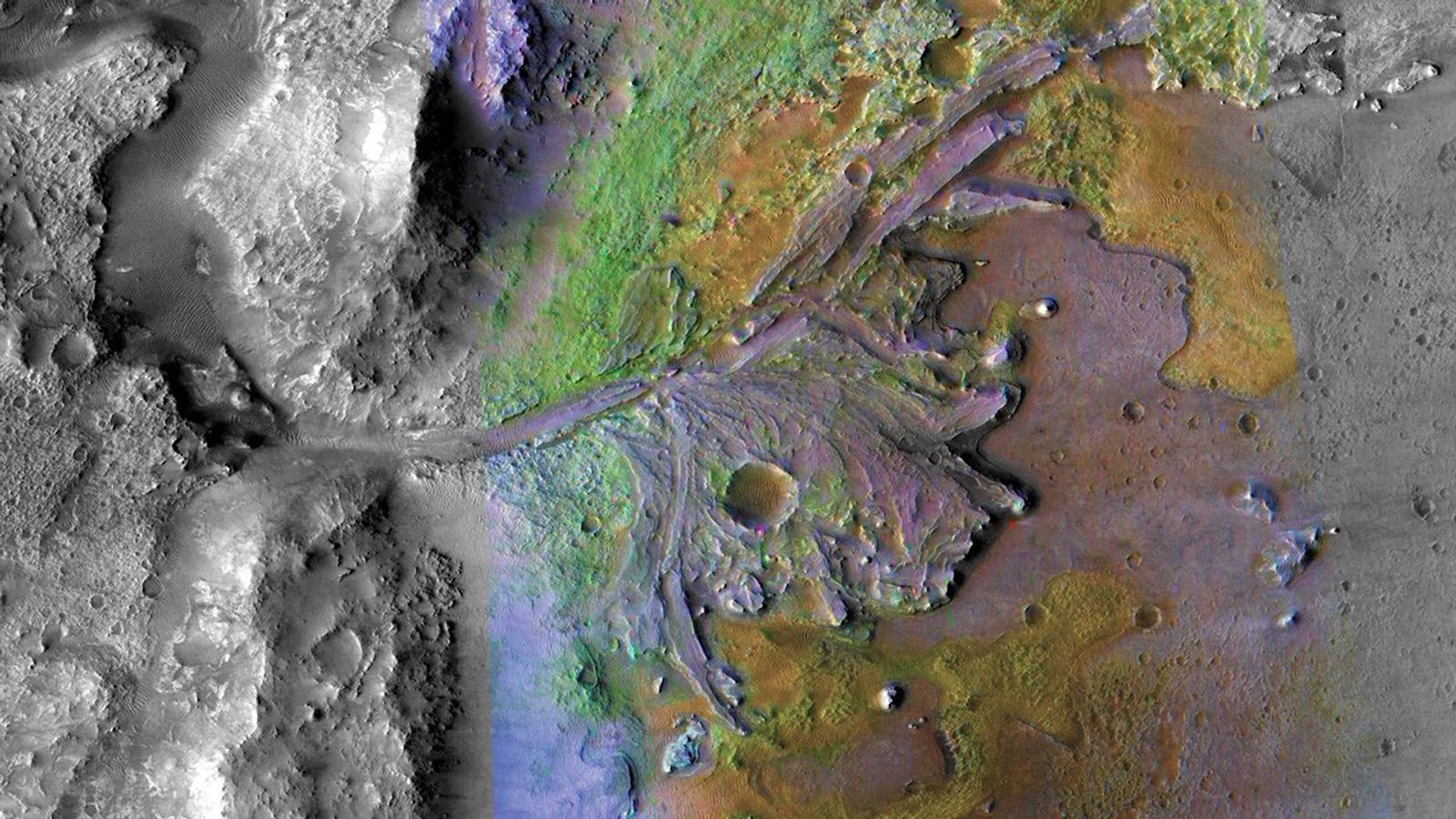

This past week, the Perseverance rover has driven to a rock outcrop called Echo Creek, situating itself just west of the Belva crater rim peppered with large flagstone rocks suitable for its next task: abrasion.

Although successfully executed countless times over the past two years, abrading and sampling are still non-deterministic activities. Rocks may fracture or reorient during preload application or the high energy drilling operations. Alternatively, the drill stabilizers or the rover itself may slip. Rover planners do their best to select stable rocks, assess slip risks, and evaluate arm motions to maximize success, all without minimizing science return. But Mars may throw a few curveballs, and it falls on the rover to protect itself in real-time.

To ensure its own safety, the robotic arm and drill software has numerous fault protections that are active during motions, of which three types are listed below:

- Force Torque Sensor (FTS) fault protection: ensures the observed force and moment loads measured from the FTS under the turret are within acceptable hardware safety limits.

- Drill weight-on-bit (WOB) fault protection: ensures the axial force on the bit is within acceptable range. WOB in conjunction with FTS loads helps determine the load through the stabilizers versus the bit.

- Nadir fault protection: ensures the rover tilt does not change by a preset magnitude during arm operations

These fault protection limits include multiple settings as well – such as the averaging period – all of which were determined through analysis and testing. If faults are triggered by a dynamic event, such as a rock fracture or stabilizer slip, an error flag is set within software to discontinue further motions that may exacerbate the situation and risk hardware safety.

Once faults are observed, the operations team may inspect data the following day to determine the root cause and path forward. While these faults can appear to be a misfortune, they still provide extremely useful insight into terrain properties, and add to the repertoire of knowledge to better predict and react to these events.

Written by Thirupathi Srinivasan, Robotic Systems Engineer at NASA's Jet Propulsion Laboratory