Brandon Chalifoux

Assistant Professor

Education

- Ph.D. (2019) • Mechanical Engineering • Massachusetts Institute of Technology

- M.S. (2014) • Mechanical Engineering • Massachusetts Institute of Technology

- B.S. (2008) • Mechanical Engineering • Rice University

Current Position

- Assistant Professor of Optical Sciences

- Assistant Professor of Aerospace and Mechanical Engineering James C. Wyant College of Optical Sciences

- University of Arizona, Tucson, AZ

- Directs the Lightweight Optics Lab and teaches optomechanical engineering courses.

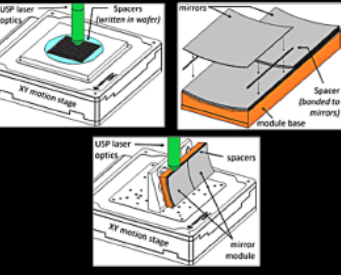

(All) Three panels illustrate our process for fabricating X-ray mirror stacks and adjusting their alignment to meet nanometer alignment tolerances.

(upper left) An ultrafast laser optical system writes patterns in a glass wafer by firing the laser as a motion stage translates the wafer along a specified trajectory.

(upper right) Spacers and mirrors are assembled to make stacks of X-ray telescope mirrors. The stacks are composed of at 6 or more curved mirrors, concave side up.

(lower) A stack is mounted on its side on a precision motion stage, with an ultrafast laser focusing into the spacers that separate the X-ray mirrors. The stage translates the mirror stack along a specified trajectory and the laser is fired into the spacer at specified locations to create strain and adjust alignment of the mirrors.

Technology Interests

- High-resolution X-ray optics

- Ultraprecision optomechanical system engineering

- Precision metrology

- Micro- to macro-scale strain engineering

- Novel techniques in ultrafast laser-based materials processing

Goals and Aspirations

- Advance astrophysics research capabilities through optomechanical technology development

- Create techniques to build extremely high-resolution, high-throughput space telescopes

- Build interconnected science and engineering teams to enable future scientific discovery

- Educate highly capable future scientists and engineers to strengthen the nation’s workforce