PROJECT

Broadband Mirror Coatings for Future NASA Observatory

SNAPSHOT

A team at GSFC is investigating techniques for creating highly reflective aluminum mirrors sensitive to the far-ultraviolet in addition to the infrared, optical, and visible wavelengths.

The more reflective a telescope mirror is at far-ultraviolet (FUV) wavelengths, the better the images it can collect. Scientists and engineers at NASA Goddard Space Flight Center (GSFC) are able to produce telescope mirror coatings with the highest reflectance ever reported in the far-ultraviolet (FUV) spectral range. Now, they have developed a new type of mirror coating envisioned for use on the mirrors of the proposed successors to the James Webb Space Telescope—the Large Ultraviolet/Optical/Infrared Surveyor (LUVOIR) and the Habitable Exoplanet Imaging Mission (HabEx). These proposed missions would tackle a broad range of astrophysics studies, from the epoch of reionization, through galaxy formation and evolution, to star and planet formation.

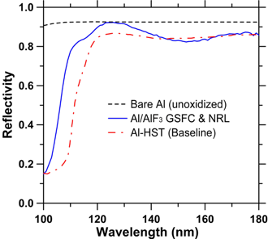

The FUV spectral region is relevant to many aspects of NASA’s Cosmic Origin (COR) program. However, performing measurements in this wavelength range has historically been quite difficult for a number of technical reasons including poor mirror reflectance in the FUV range. Consequently, the universe has only been explored by a handful of NASA astronomy missions in this spectral range. The Far Ultraviolet Spectroscopic Explorer (FUSE) observing program was the most extensive by far, but it was limited by modest effective mirror area (20 cm2 below 100 nm and 55 cm2 above 102 nm) and modest spectral resolution (R~20,000). The average reflectivity of the mirror coatings on FUSE was 60% for the Aluminum + Lithium Fluoride (Al+LiF) coating and 30% for the Silicon carbide (SiC) coating.

Improved reflectivity in itself would bring enormous gains in throughput, and the benefits of more capable optical designs enabled by higher reflectivity would increase sensitivity. Aluminum is the metal with the broadest spectral coverage. In fact, pure aluminum mirrors are highly reflective over the spectral range proposed for LUVOIR and HabEx observations (90 to 5,000 nm). However, aluminum needs to be protected from naturally occurring oxides with a thin coating of transparent material.

Unfortunately, no one has developed a coating that effectively protects and maintains a mirror’s reflectivity in the 90- to 130-nm range, also known as the Lyman Ultraviolet range, a spectral regime rich in astronomical targets and spectral lines, including potentially habitable planets beyond our solar system. The low reflectivity of coatings in this range is one of the biggest constraints in FUV telescope and spectrograph design.

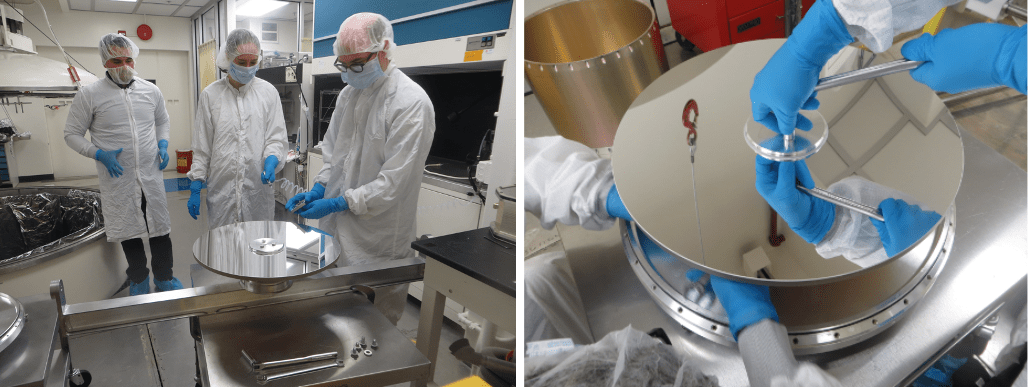

A team funded by NASA’s Science Mission Directorate and led by Manuel Quijada at GSFC is testing several new techniques and materials for creating and applying protective coatings that will produce highly reflective aluminum mirrors sensitive to the infrared, visual, and far-ultraviolet wavelengths.

Under several research grants from the Astrophysics Division’s Astrophysics Research and Analysis (APRA) program, Quijada’s team is planning to use xenon difluoride to apply a thin layer of aluminum trifluoride to an aluminum sample. Previous studies indicated that the use of xenon difluoride creates fluorine ions that tightly bind to the aluminum surface, preventing the oxidation that decreases reflectivity. The team is also investigating the use of two other thin-film deposition techniques — Ion-Assisted Physical Vapor Deposition and Atomic Layer Deposition — to apply thin films of aluminum trifluoride, which is environmentally stable compared with other coatings.

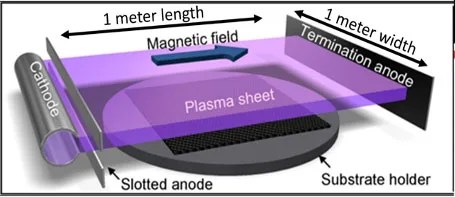

Quijada’s team is also working on a third approach, based on a partnership between GSFC and the Naval Research Laboratory (NRL) through a Strategic Astrophysics Technology (SAT) grant. This SAT project is aiming to develop aluminum-based broadband optical coatings using the NRL Large Area Plasma Processing System (LAPPS). This project is leveraging the improvements in FUV reflectivity that have been developed at GSFC involving aluminum test samples that are protected with a single Aluminum Fluoride (AlF3) dielectric overcoat. The goal is to produce large (1+ meter class) mirrors using the LAPPS reactor at NRL and their patented e-beam plasma system. The ultimate plan is to remove oxide from bare aluminum surfaces and passivate the surface (i.e., make it less reactive) using an aluminum tri-fluoride (AlF3) layer.

The figure at left indicates that using this newly reconfigured LAPPS reactor yielded coatings with FUV reflectivity greater than 50% at 106 nm and reflectivity approximately equal to 90% at 120 nm (blue line) compared to the reflectivity of the Hubble Space Telescope (HST) mirrors prior to launch (red dashed line). Note that the coating used in the HST mirrors consisted of Al protected with magnesium difluoride (MgF2).

Preliminary studies on the passivation of thin aluminum films have already demonstrated the feasibility of the plasma process to effectively fluorinate the surface of small aluminum mirror samples without using highly corrosive hydrofluoric (HF) acid. The team is working to develop a process to treat an aluminum surface on a scale as large as 1 meter (m) in diameter. Successful completion of this effort would provide enhanced reflectors in the FUV spectral region (90-180nm), which would ultimately enable new scientific imaging capabilities for the LUVOIR and the HabEx missions.

PROJECT LEAD

Dr. Manuel A. Quijada, NASA Goddard Space Flight Center

SPONSORING ORGANIZATION

Astrophysics Research and Analysis (APRA) and Strategic Astrophysics Technology (SAT) Programs