Updated February 21, 2020

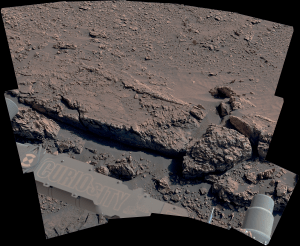

The InSight team is now trying a new technique to help the mole. They’re trying to use the scoop on the end of its robotic arm to press on the top of the mole, also called its back cap.

InSight to Push on Top of the 'Mole'Engineers have a plan for pushing down on the heat probe, which has been stuck at the Martian surface for a year. Read more ›

InSight to Push on Top of the 'Mole'Engineers have a plan for pushing down on the heat probe, which has been stuck at the Martian surface for a year. Read more ›

Updated October/November 2019

Q: Why can't you pick up the 'mole' and move it to another spot?

A: The mole is part of the instrument called the Heat Flow and Physical Properties Package, or HP3, and was designed to be housed within HP3's support structure. The support structure of HP3 was outfitted with a knob, or "grapple point," that the robotic arm can grasp in order to move it from the lander's deck onto the Martian surface. Designed to be housed within the support structure, the mole itself has no grapple point and was not intended to be grasped or moved.

Even if the mole could be moved, relocating it would be an unlikely solution. The team is confident that the probe has been unable to dig because the soil doesn't provide enough friction. Anywhere you move the mole near the lander would likely pose the same problem. The strategy of "pinning" — pressing the robotic arm's scoop against the side of the mole — compensates for that lack of friction and helped the mole progress downward in early October.

Q: Why doesn't the mole include a drill?

A: A drill would require a much bigger, more powerful motor than what the InSight lander can accommodate. It would also require more power than the solar-powered lander can practically provide. What's more, a drill would require rigging to stabilize it as the motor spins, just like with a drill press. Rigging cancels out the force of a drill's spin, which would otherwise spin the motor in the other direction.

About 1 inch (2.7 centimeters) in diameter and about 16 inches (40 centimeters) long, the mole was designed to be light enough and small enough to suit the constraints of the lander deck. It functions somewhat like a pile driver: A motor attached to a gearbox inside the mole slowly compresses and then quickly releases a spring that drives a tungsten hammer against the interior of the mole tip, at a pace of one stroke every 3.7 seconds.

Q: Are you sure the mole didn't hit a rock?

A: Most of the team remains confident that a rock didn't cause the mole to rebound. The landing site, Elysium Planitia, was selected partly because it has so few visible rocks, implying few large subsurface rocks. The mole is strong enough to nudge small rocks out of its way and was designed to go around medium-size rocks — anything less than about 4 inches (10 centimeters) in diameter — once it's fully buried.

Further analysis will be required to determine why the mole backed out of the hole once there was too little mole exposed above the Martian surface to make pinning possible.

Q: How much of a factor is Mars' reduced gravity when trying to replicate the mole’s behavior on Earth?

A: The robotic arm testbed at NASA's Jet Propulsion Laboratory in Pasadena, California, uses weight models (nonfunctional replicas of the instruments that are the weight they would be on Mars) to simulate the effects of the Red Planet's reduced gravity. But certain experiments, like ones involving the mole digging, cannot be fully re-created: The team can't simulate low gravity at the Earth's surface. It wouldn't be possible to make a lightweight version of the mole for testing that has the same digging power as the mole that's on Mars.

Q: Is there any chance the hammering mechanism is damaged?

A: The InSight science team hasn't seen any noticeable difference between the performance of the mole on Mars and what has been seen in testing on Earth. InSight's seismometer can detect the vibrations from each of the mole's hammer strokes and is being used to analyze tiny (millisecond-level) variations in each stroke. To date, the team hasn't seen evidence that the hammering mechanism is damaged.

Q: Despite the challenges it poses to the mole, is the soil teaching us anything new about Mars?

A: Absolutely! The mole was designed with the loose, sandy soils seen by the Spirit and Opportunity rovers in mind. The soil under InSight is mechanically different from what we've seen at other landing sites. The formation of the pit around the probe, the resistance of the pit to collapsing and the interesting self-extraction of the mole are all surprising and will be investigated by the InSight science team to revise its understanding of the formation and variations of the Martian soil.

Q: Why push the mole from the side rather than applying pressure from above?

A: Pushing from the side allowed the InSight team to almost fully bury the mole in October 2019; it's a technique that appears to work well. The team wants to avoid pressing on top of the mole, where a sensitive tether supplying power and relaying data sticks out. It's still possible that the team will press down on the top of the mole if there are no other options, but they have been pressing from the side until now because it's safer for all of the hardware.

Originally posted June 5, 2019

There's a new plan to get InSight's "mole" moving again. The following Q&As with two members of the team answer some of the most common questions about the burrowing device, part of a science instrument called the Heat Flow and Physical Properties Package (HP3).

HP3 Principal Investigator Tilman Spohn of the German Aerospace Center (DLR), which provided the instrument.

Q: What do you suspect is preventing the mole from digging further?

A: We don't know for sure, because we can't see underground. That's why we want to lift the support structure. But we're fairly confident the problem is a lack of friction in the soil.

The mole is designed for loose soil to flow around it, providing friction that keeps the mole from bouncing backwards with recoil. The soil around InSight provides much less friction than what we've seen before on Mars. We have several ideas for why this is. One is that the soil compacts and holds together so well that the mole may have created a small cavity around itself while hammering, preventing it from getting the friction it needs to dig. Tests conducted in Germany have confirmed this could happen.

There's also the possibility that we've hit a rock. The mole was designed to go around smaller rocks — no bigger than a few inches [or centimeters] in size — but it may be pinned between the rock and the support structure. If that's the case, moving the support structure may allow it to keep digging. If it's hit a larger rock, there's not much we can do.

Q: Why couldn't the team anticipate the soil issue or hitting a rock?

A: We always knew there were environmental risks that could stop the mole. What we did is prepare as best we could so that they were calculated risks.

The low-friction soil was unexpected: Everywhere else on Mars, soil has been different, which was what the mole was built for. We also knew there would be rocks underground, so we deliberately chose a landing site that was flat and had as few rocks as possible on the surface. Based on what we can see, the chances of hitting a rock this close to the surface that the mole can't go around is only a few percent.

Q: What will happen once you lift the support structure?

A: It depends on what we see. First, we'll try a short hammering sequence with the mole. Then, regardless of whether there's a cavity around the mole, we will likely press on the soil with a small scoop on the robotic arm to provide a load on the surface. Our calculations suggest that this should increase the friction and could help it dig.

Q: When would that occur?

A: We hope to lift the support structure by the end of June and to have our next steps decided by mid-July. After that, we will need time to run more tests.

Engineer-scientist Troy Hudson of NASA's Jet Propulsion Laboratory in Pasadena, California, which leads the InSight mission.

Q: Why are you lifting the support structure in three steps?

A: There are springs inside of the support structure that may still be in contact with the top of the mole. If that's the case, we want to be careful lifting the structure so that we don't accidentally pull the mole out. If that happened, we won't be able to insert it back into its hole in the soil. So we'll lift the support structure a little bit at a time, checking to make sure the mole isn't coming with it.

Q: Why has it taken so much time to plan these next steps?

A: We don't want to take an action that makes the situation worse, so we've been moving very carefully. InSight is also a Discovery class mission, meaning it was meant to be more affordable — and to accept more risk — than a flagship NASA mission. So the team is very small; we don't command the lander every day, and commands that are sent up need to be rigorously tested to make sure they'll work the way we want them to. We want every action to be safe for HP3, the robotic arm and InSight's seismometer, which is very close by.

About InSight

JPL manages InSight for NASA's Science Mission Directorate. InSight is part of NASA's Discovery Program, managed by the agency's Marshall Space Flight Center in Huntsville, Alabama. Lockheed Martin Space in Denver built the InSight spacecraft, including its cruise stage and lander, and supports spacecraft operations for the mission.

A number of European partners, including France's Centre National d'Études Spatiales (CNES) and the German Aerospace Center (DLR), are supporting the InSight mission. CNES provided the Seismic Experiment for Interior Structure (SEIS) instrument to NASA, with the principal investigator at IPGP (Institut de Physique du Globe de Paris). Significant contributions for SEIS came from IPGP; the Max Planck Institute for Solar System Research (MPS) in Germany; the Swiss Federal Institute of Technology (ETH Zurich) in Switzerland; Imperial College London and Oxford University in the United Kingdom; and JPL. DLR provided the Heat Flow and Physical Properties Package (HP3) instrument, with significant contributions from the Space Research Center (CBK) of the Polish Academy of Sciences and Astronika in Poland. Spain's Centro de Astrobiología (CAB) supplied the temperature and wind sensors.

News Media Contact

Andrew Good

Jet Propulsion Laboratory, Pasadena, Calif.

818-393-2433

andrew.c.good@jpl.nasa.gov

Alana Johnson

NASA Headquarters, Washington

202-358-1501

alana.r.johnson@nasa.gov