Technology Development

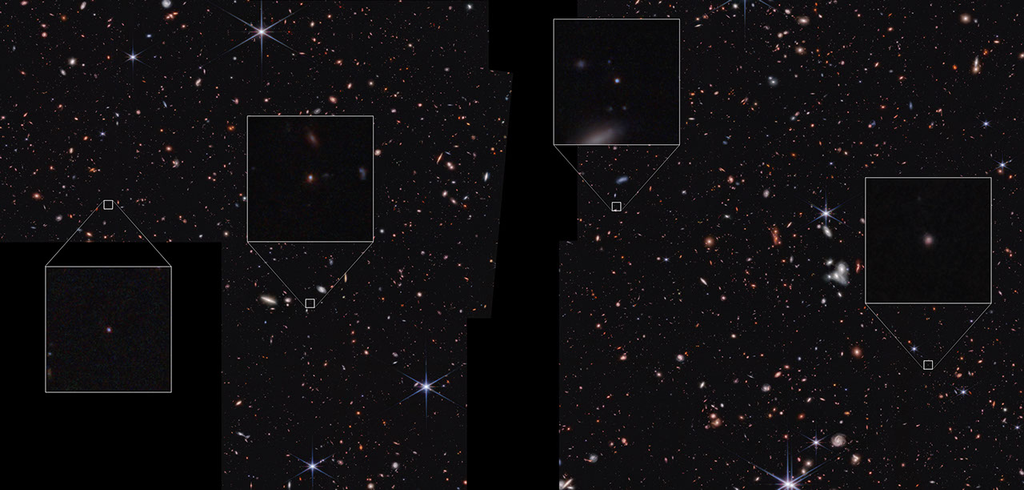

An X-ray telescope is characterized by four parameters: angular resolution, effective area, mass, and production cost. Researchers at NASA GSFC have developed a new X-ray mirror technology that is expected to improve one or more of these parameters by at least an order of magnitude, compared to the mirrors currently employed on missions such as the Chandra X-ray Observatory and the Nuclear Spectroscopic Telescope Array (NuSTAR).

This mirror technology combines a polishing process used for fabricating optics of the highest quality with use of monocrystalline silicon—a material used in the semiconductor industry. Monocrystalline silicon is free of internal stress and thereby enables development of extremely thin (less than 1 mm) and lightweight (areal density less than 2.5 kg/m2) mirrors. The GSFC team has been working to perfect this technology since 2011, and in 2016 they developed a process to make Wolter-I (parabolic or hyperbolic) mirrors as thin as 0.5 mm with figure quality better than 3 arcsec—a tenfold improvement over the NuSTAR mirrors. In parallel, the team developed a bonding process that preserves the figure and alignment of these thin mirrors, while enabling them to sustain a typical space launch vibration environment.

Impact

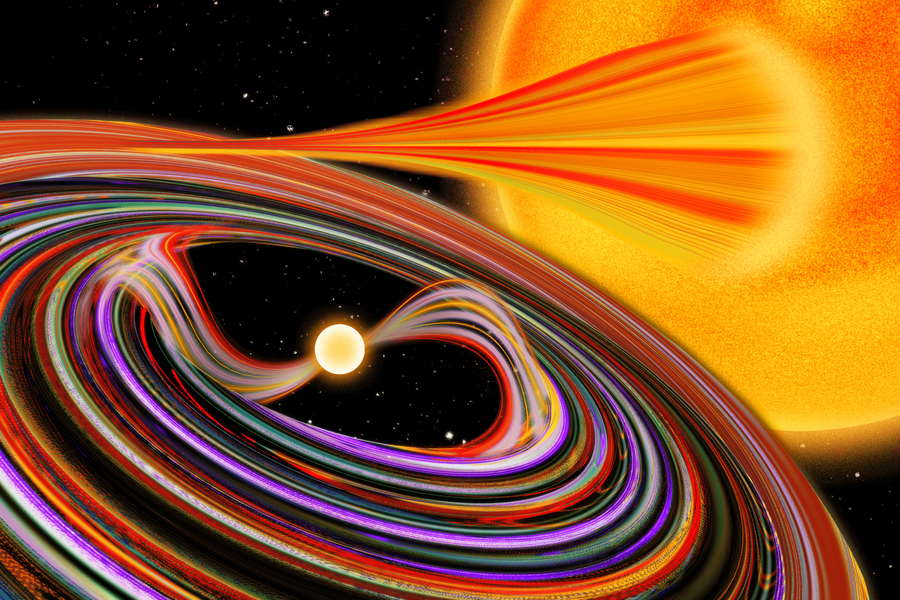

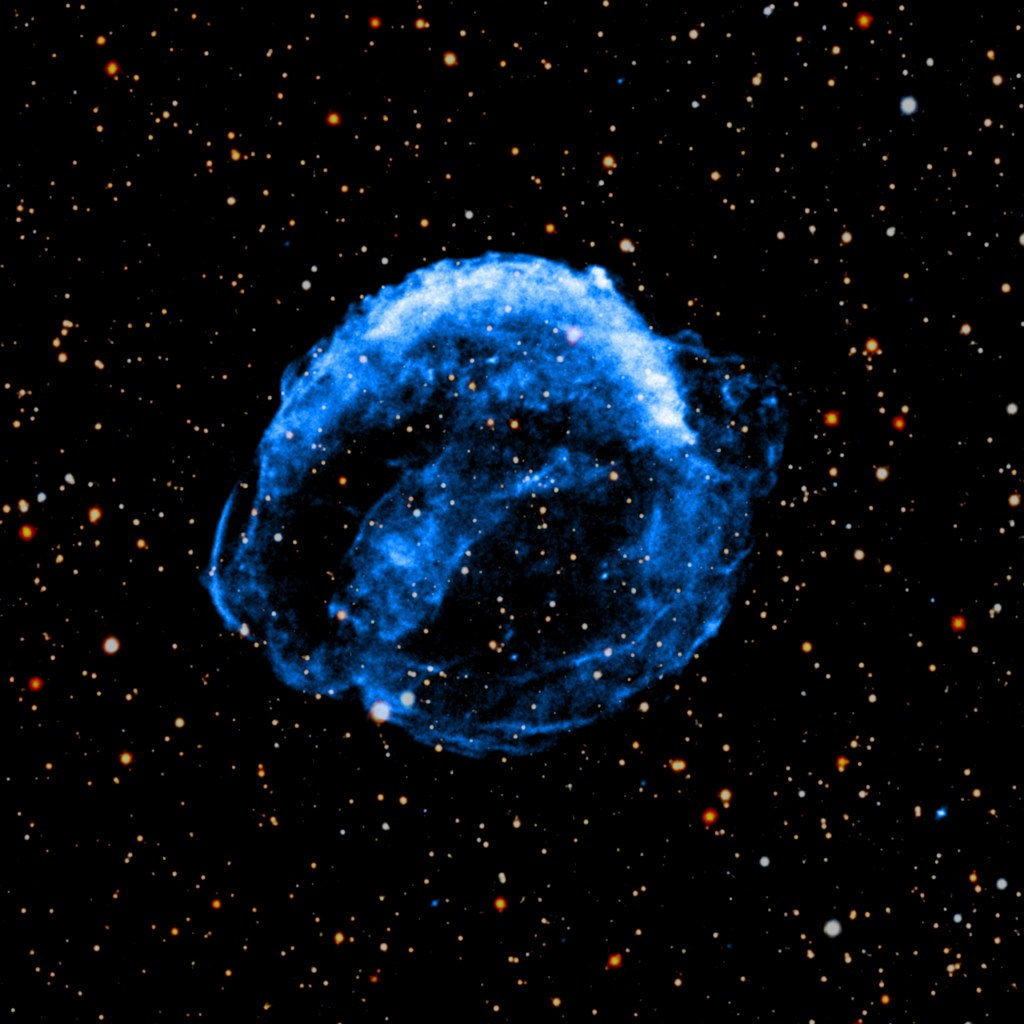

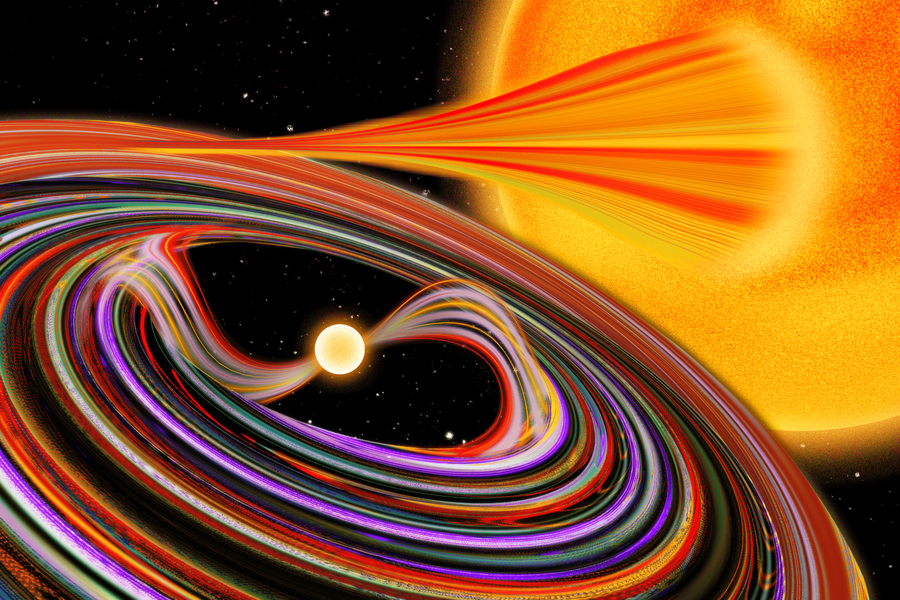

This mirror technology will enable observation and study of supermassive black holes, galaxy clusters, and the centers of nearby galaxies, where myriad stellar binaries containing compact objects such as neutron stars and black holes reside. This monocrystalline silicon mirror technology has the potential to enable a quantum jump in capability with a mass and production cost comparable to today’s technology. The modular nature of this mirror technology, where a large mirror assembly is constructed of many small mirror segments, makes it highly amenable to parallel and mass production, both of which are essential for meeting schedule and cost requirements of future missions. Likewise, this technology is also suitable for making mirror assemblies for missions of all sizes.

Status and Future Plans

The team will refine the mirror fabrication and bonding processes to improve the figure quality by at least an order of magnitude in the next five to ten years, so the technology will be ready to implement on a major X-ray observatory in the 2020s.

Sponsoring Organization

SMD’s Astrophysics Division supports this development effort via the APRA and SAT programs, and William Zhang at GSFC is the PI.