PROJECT

Plant Water Management (PWM)

SNAPSHOT

NASA is demonstrating that even without the help of gravity, hydroponic plant watering methods can enable plant habitats aboard crewed or robotic space missions.

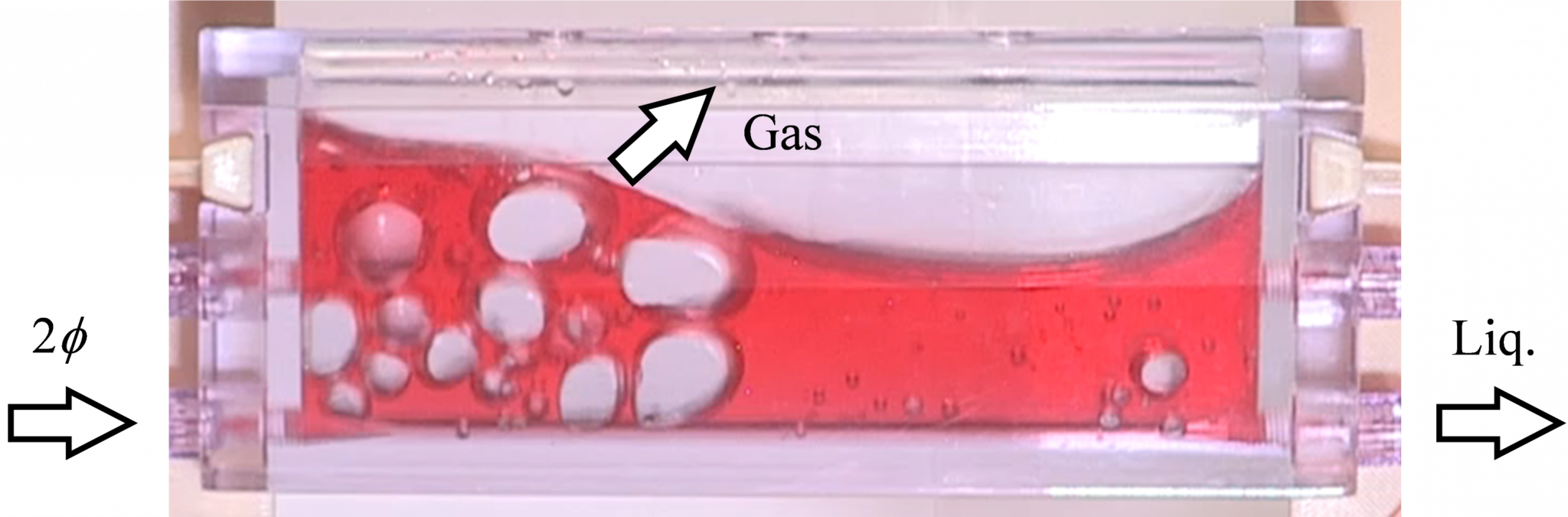

On Earth, plants draw water upwards through the roots against gravity, via capillary action, which orients the plant and enables display of its canopy (foliage and branches) for optimal photosynthesis and transpiration. The plant grows above the nutrient-rich soil as the water recedes into the soil, and oxygen from the air between the soil particles diffuses into root hair, maintaining a balance of oxygenation in the water and a dry stem. Hydroponic watering systems on Earth achieve a similar result without the soil by providing a continuous flow of aerated nutrient-rich water, which allows the plant to take up only what it needs; gravity again assures growth direction and a dry stem. Providing water to plants at the varied rates they require is difficult without gravity—which is exactly what is required of plant watering systems aboard spacecraft. Of the many methods pursued by NASA, hydroponics offers key performance advantages: low system mass, natural aeration, simplicity, and potential for automation. But how can hydroponics channels work in space without gravity to define an “up” or “down” or a “top” or “bottom?”.

NASA has initiated a series of experiments to test capillary hydroponics onboard the International Space Station (ISS). These Plant Water Management (PWM) experiments seek to exploit the combined effects of surface tension, wetting, and hydroponic channel geometry to ensure proper water flow in space to mimic the role of gravity on Earth. Terrestrial hydroponic systems work so well, are so simple, have few failure modes, and require no media such as soil. But can we design a system in space that can replicate such characteristics? Specifically, how can we assure that the nutrient-rich water will flow safely along the “bottom” of hydroponics channels in a low-gravity environment?

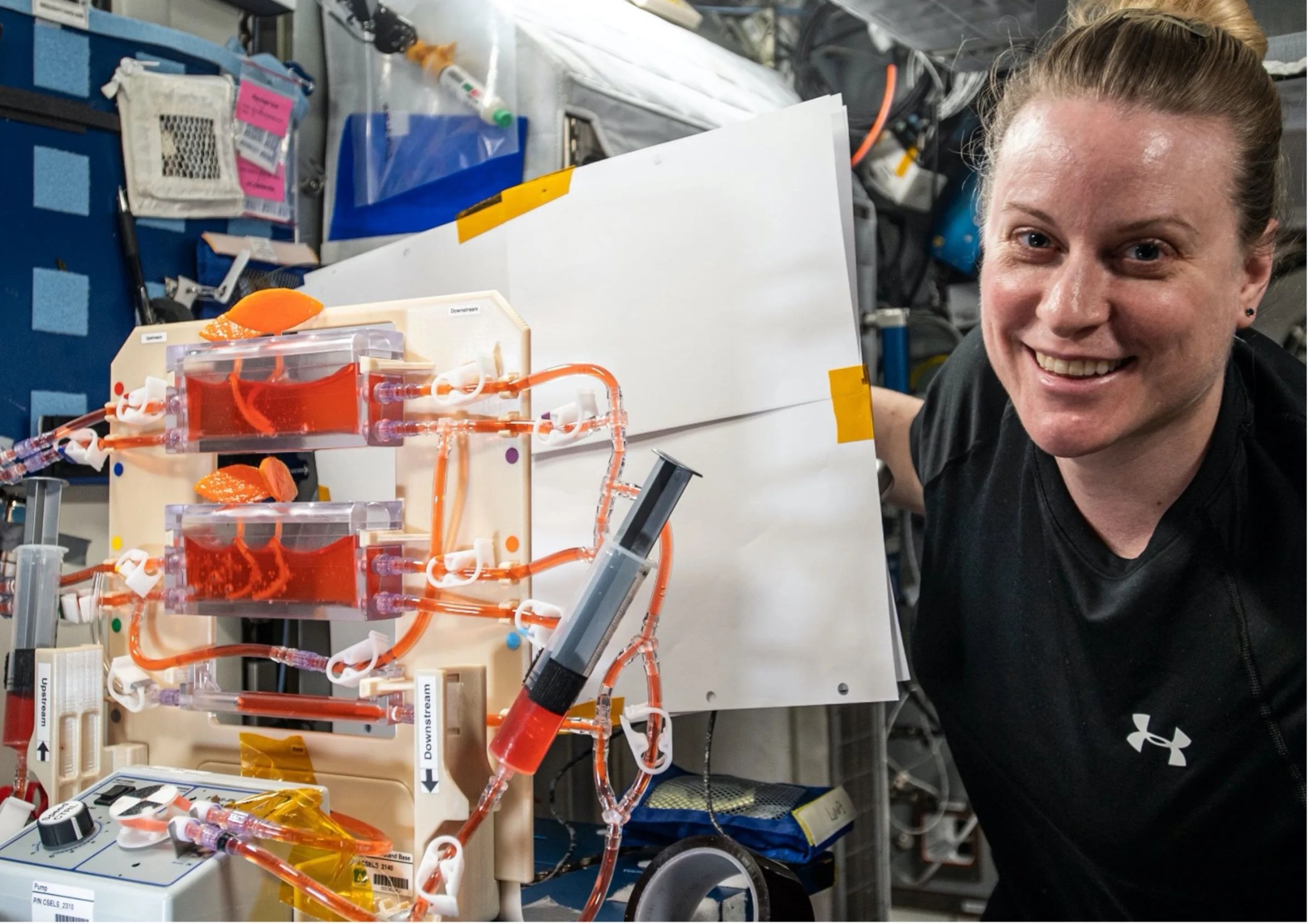

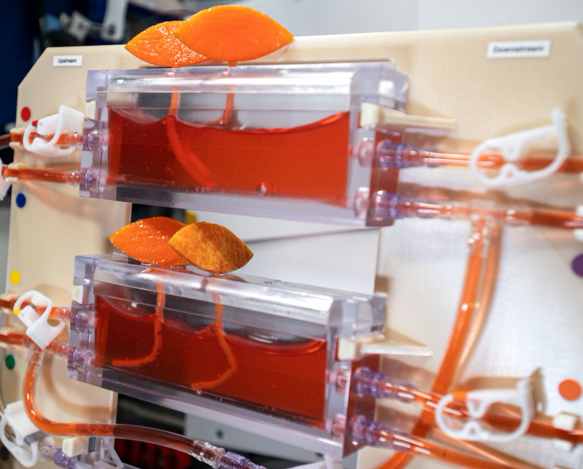

The PWM hardware consists of a variable-speed metering pump, tubing, assorted valves, syringes, and several sets of capillary fluidic hydroponics channels and tubing harnesses. This setup enables a wide range of parameters to be tested—e.g., gas and liquid flow rates, fill levels, inlet/outlet configurations, bubble separation methods, and plant types, number, and order. Most of the equipment shipped to the ISS consists of 3-D printed flight-certified materials. The crew assembles the various system configurations on a workbench in the open cabin of the ISS and then executes the experiments, including routine communication with the PWM research team on the ground. All of the quantitative data is collected via a single high-definition video camera.

The PWM hardware and procedures are designed to incrementally test the system’s capabilities including priming, single-channel operation, parallel-channel operation, reverse flow, serial flow, limits of operation, stability during perturbations, start-up, shut-down, and myriad plant-insertion, saturation, stable flow, and plant-removal steps.

With each successful demonstration, the low-gravity hydroponics plumbing approach increases its Technology Readiness Level (TRL) and will eventually be used in demonstrations with actual plants, which will hopefully be performed in connection with plant habitats already on ISS (i.e., the Advanced Plant Habitat). PWM experiments currently underway on ISS focus on passive liquid delivery, fill level maintenance, serial operation, passive steady aeration, and more. Designs are in work for follow-on demonstrations targeting specific crop types, automation methods, and channel deployment architecture.

PROJECT LEAD

Dr. Mark Weislogel, Portland State University