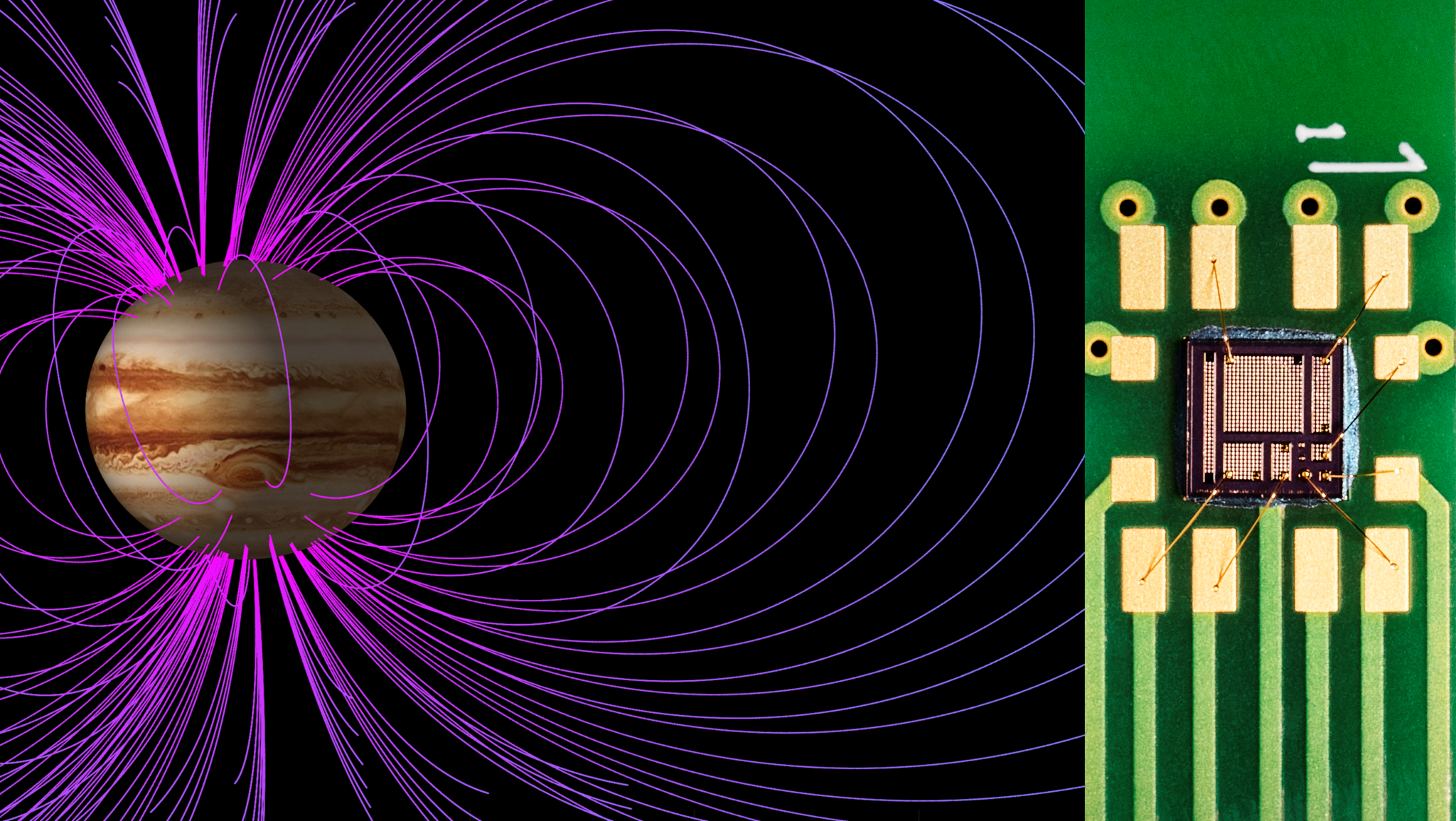

Magnetic fields are everywhere in our solar system. They originate from the Sun, planets, and moons, and are carried throughout interplanetary space by solar wind. This is precisely why magnetometers—devices used to measure magnetic fields—are flown on almost all missions in space to benefit the Earth, Planetary, and Heliophysics science communities, and ultimately enrich knowledge for all humankind. These instruments can remotely probe the interior of a planetary body to provide insight into its internal composition, structure, dynamics, and even evolution based on the magnetic history frozen into the body’s crustal rock layers. Magnetometers can even discover hidden oceans within our solar system and help determine their salinity, thereby providing insight into the potential habitability of these icy worlds.

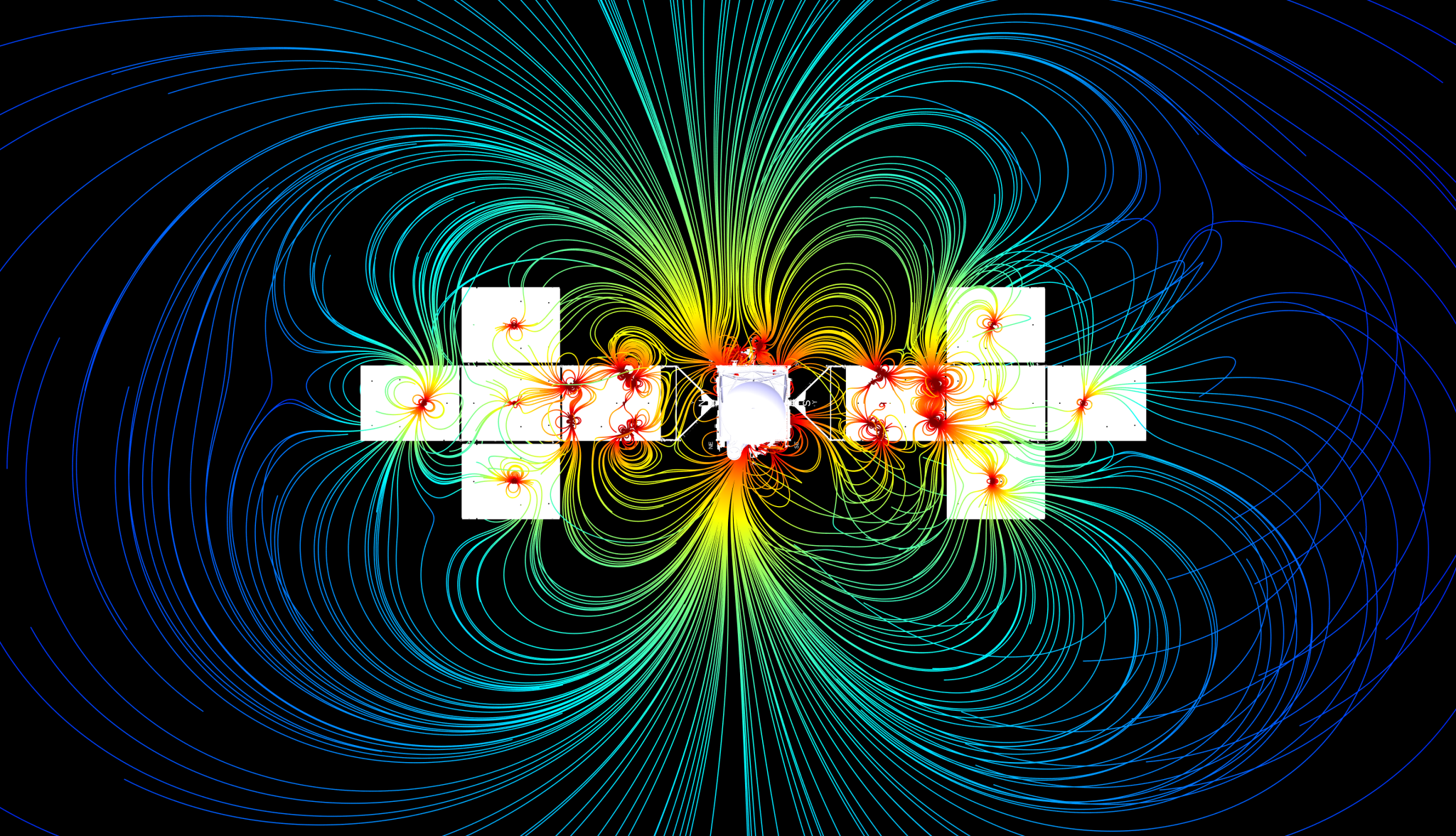

Fluxgates are the most widely used magnetometers for missions in space due to their proven performance and simplicity. However, the conventional size, weight, and power (SWaP) of fluxgate instruments can restrict them from being used on small platforms like CubeSats and sometimes limit the number of sensors that can be used on a spacecraft for inter-sensor calibration, redundancy, and spacecraft magnetic field removal. Traditionally, a long boom is used to distance the fluxgate magnetometers from the contaminate magnetic field generated by the spacecraft, itself, and at least two sensors are used to characterize the falloff of this field contribution so it can be removed from the measurements. Fluxgates also do not provide an absolute measurement, meaning that they need to be routinely calibrated in space through spacecraft rolls, which can be time and resource intensive.

An SMD-funded team at NASA’s Jet Propulsion Laboratory in Southern California has partnered with NASA’s Glenn Research Center in Cleveland, Ohio to prototype a new magnetometer called the silicon carbide (SiC) magnetometer, or SiCMag, that could change the way magnetic fields are measured in space. SiCMag uses a solid-state sensor made of a silicon carbide (SiC) semiconductor. Inside the SiC sensor are quantum centers—intentionally introduced defects or irregularities at an atomic scale—that give rise to a magnetoresistance signal that can be detected by monitoring changes in the sensor’s electrical current, which indicate changes in the strength and direction of the external magnetic field. This new technology has the potential to be incredibly sensitive, and due to its large bandgap (i.e., the energy required to free an electron from its bound state so it can participate in electrical conduction), is capable of operating in the wide range of temperature extremes and harsh radiation environments commonly encountered in space.

Team member David Spry of NASA Glenn indicates, “Not only is the SiC material great for magnetic field sensing, but here at NASA Glenn we’re further developing robust SiC electronics that operate in hot environments far beyond the upper temperature limitations of silicon electronics. These SiC-based technologies will someday enable long-duration robotic scientific exploration of the 460 °C Venus surface.”

SiCMag is also very small— the sensor area is only 0.1 x 0.1 mm and the compensation coils are smaller than a penny. Consequently, dozens of SiCMag sensors can easily be incorporated on a spacecraft to better remove the complex contaminate magnetic field generated by the spacecraft, reducing the need for a long boom to distance the sensors from the spacecraft, like implemented on most spacecraft, including Psyche (see figure below).

SiCMag has several advantages when compared to fluxgates and other types of heritage magnetometers including those based on optically pumped atomic vapor. SiCMag is a simple instrument that doesn’t rely on optics or high-frequency components, which are sensitive to temperature variations. SiCMag’s low SWaP also allows for accommodation on small platforms such as CubeSats, enabling simultaneous spatial and temporal magnetic field measurements not possible with single large-scale spacecraft. This capability will enable planetary magnetic field mapping and space weather monitoring by constellations of CubeSats. Multiplatform measurements would also be very valuable on the surface of the Moon and Mars for crustal magnetic field mapping, composition identification, and magnetic history investigation of these bodies.

SiCMag has a true zero-field magnetic sensing ability (i.e., SiCMag can measure extremely weak magnetic fields), which is unattainable with most conventional atomic vapor magnetometers due to the requisite minimum magnetic field needed for the sensor to operate. And because the spin-carrying electrons in SiCMag are tied up in the quantum centers, they won’t escape the sensor, meaning they are well-suited for decades-long journeys to the ice-giants or to the edges of the heliosphere. This capability is also an advantage of SiCMag’s optical equivalent sibling, OPuS-MAGNM, an optically pumped solid state quantum magnetometer developed by Hannes Kraus and matured by Andreas Gottscholl of the JPL solid-state magnetometry group. SiCMag has the advantage of being extremely simple, while OPuS-MAGNM promises to have lower noise characteristics, but uses complex optical components.

According to Dr. Andreas Gottscholl, “SiCMag and OPuS-MAGNM are very similar, actually. Progress in one sensor system translates directly into benefits for the other. Therefore, enhancements in design and electronics advance both projects, effectively doubling the impact of our efforts while we are still flexible for different applications.”

SiCMag has the ability to self-calibrate due to its absolute sensing capability, which is a significant advantage in the remote space environment. SiCMag uses a spectroscopic calibration technique that atomic vapor magnetometers also leverage called magnetic resonance (in the case of SiCMag, the magnetic resonance is electrically detected) to measure the precession frequency of electrons associated with the quantum centers, which is directly related to the magnetic field in which the sensor is immersed. This relationship is a fundamental physical constant in nature that doesn’t change as a function of time or temperature, making the response ideal for calibration of the sensor’s measurements. “If we are successful in achieving the sought-out sensitivity improvement we anticipate using isotopically purer materials, SiC could change the way magnetometry is typically performed in space due to the instrument’s attractive SWaP, robustness, and self-calibration ability,” says JPL’s Dr. Corey Cochrane, principal investigator of the SiCMag technology.

NASA has been funding this team’s solid-state quantum magnetometer sensor research through its PICASSO (Planetary Instrument Concepts for the Advancement of Solar System Observations) program since 2016. A variety of domestic partners from industry and academia also support this research, including NASA’s Glenn Research Center in Cleveland, Penn State University, University of Iowa, QuantCAD LLC, as well as international partners such as Japan’s Quantum Materials and Applications Research Center (QUARC) and Infineon Technologies.

Acknowledgment: The research was carried out at the Jet Propulsion Laboratory, California Institute of Technology, under a contract with the National Aeronautics and Space Administration (80NM0018D0004) and the NASA Glenn Research Center.

Project Lead(s):

Dr. Corey Cochrane, Dr. Hannes Kraus, Jet Propulsion Laboratory/California Institute of Technology

Dr. Phil Neudeck, David Spry, NASA Glenn Research Center

Sponsoring Organization(s):

Science Mission Directorate PICASSO, JPL R&D fund