Technology Development

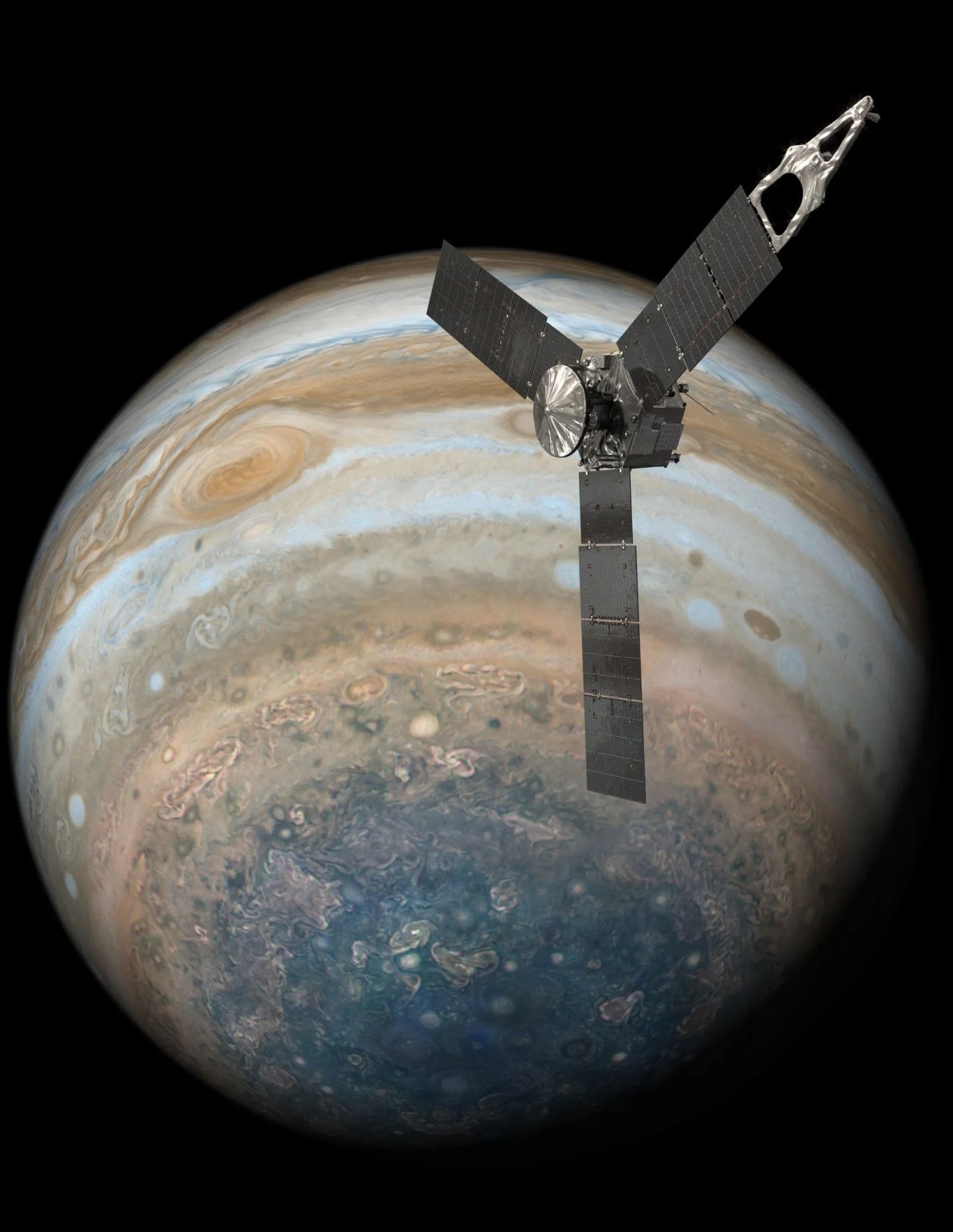

Radioisotope power systems (RPS) provide the efficient, long-lasting power sources vital to the success of numerous NASA space missions. RPS convert heat generated from the radioactive decay of plutonium-238 oxide into electricity that powers spacecraft and instruments. The current “off-the-shelf” flight-proven RPS is the Multi-Mission Radioisotope Thermoelectric Generator (MMRTG), which relies on power-generating thermoelectric (TE) couples using heritage materials (lead-telluride/ tellurium-antimony-germanium-silver alloys). NASA SMD is sponsoring technology development efforts to improve Radioisotope Thermoelectric Generator (RTG) performance, both in terms of the thermal-to-electric conversion efficiency (~ 6.3% at beginning of life - BOL) and the degradation rate during the 17-year design life.

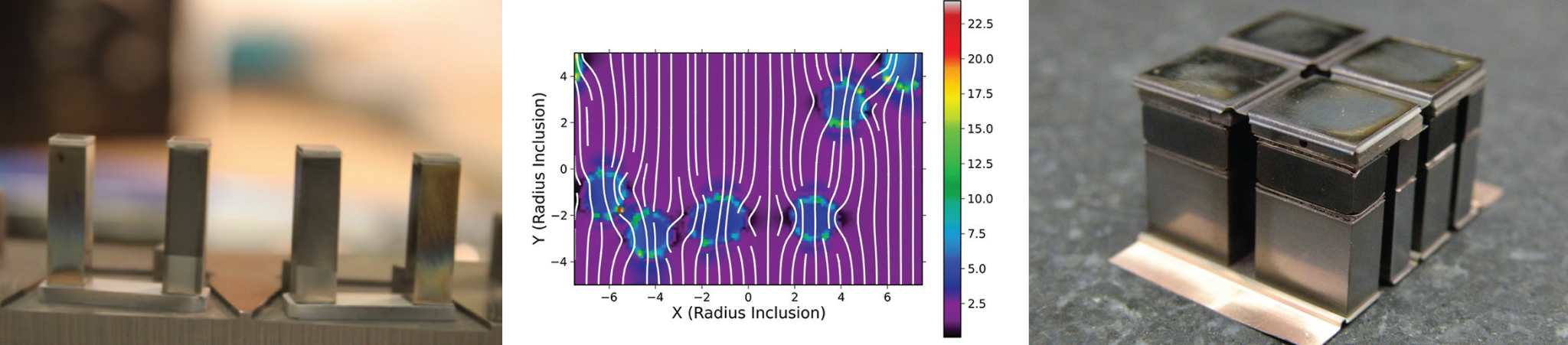

NASA SMD’s steady investment in thermoelectric materials and device research and development has led to significant technology breakthroughs. Recently, researchers have discovered several classes of new high-efficiency materials with an excellent potential for infusion into future RTGs. These materials—skutterudites (SKD, based on CoSb3), Zintl phases (such as Yb14MnSb11) and lanthanum telluride (La3-xTe4)—possess highly complex crystal structures, have excellent thermal and chemical stability across the range of very low temperatures (1273 K to 473 K) characteristic of the space environment where RTG operate, and offer significant opportunities for further increases in performance. In 2016, initial testing of new thermocouple devices combining these materials demonstrated a factor of two improvement in conversion efficiency over heritage technologies.

Impact

Industry is currently maturing lower-temperature (up to 900 K) SKD materials technology for potential infusion into an Enhanced Multi-Mission Radioisotope Thermoelectric Generator (eMMRTG). The eMMRTG would offer a 25% boost in power at BOL that would grow to least 50% at end-of-design life (17 years after BOL), thanks to its estimated lower degradation rate. Combining this skutterudite technology with the higher-temperature 14-1-11 Zintl and La3-xTe4 materials into segmented device technology (segmented elements combine several materials into a single, wide-temperature, high-efficiency device that utilizes each material in its most efficient temperature range) could enable more capable RTG concepts. Such concepts could be modular, accommodate a wide range of power system sizing (from tens to hundreds of watts), and achieve much higher specific power than the MMRTG. This SMDfunded technology has also attracted interest for application to various terrestrial fields of use concerning industrial waste heat recovery and energy efficiency.

Status and Future Plans

Several significant technology developments were completed in 2016. A new method— composite assisted funneling of electrons (CAFE)—was identified for improving the efficiency of TE materials such as 14-1-11 Zintls and La3-xTe4. The CAFE mechanism does not appear to be material-specific and could provide a new method to improve the efficiency of a wide range of thermoelectric materials. For SKD technology, SMD-sponsored efforts focused on developing device component technologies resilient enough to operate within the hermetically sealed convertor “cavity” of the eMMRTG. Researchers also changed the materials used to metallize the SKD elements and altered the composition of the metallic bonding layers used to fabricate the couples. Extended performance testing in a relevant operating environment confirmed the resilience of the new SKD couple configurations to residual moisture and gases. Completion of the SKD technology maturation for a potential transition to the eMMRTG flight system development is currently scheduled at end of 2018.

Sponsoring Organization

PSD’s Radioisotope Power System Program is providing funding to the Thermoelectric Technology Development Project (TTDP) managed by Jean-Pierre Fleurial at the NASA Jet Propulsion Laboratory (JPL). The TTDP is led by JPL and includes participation by the NASA Glenn Research Center, academia, and industry.