Technology Development

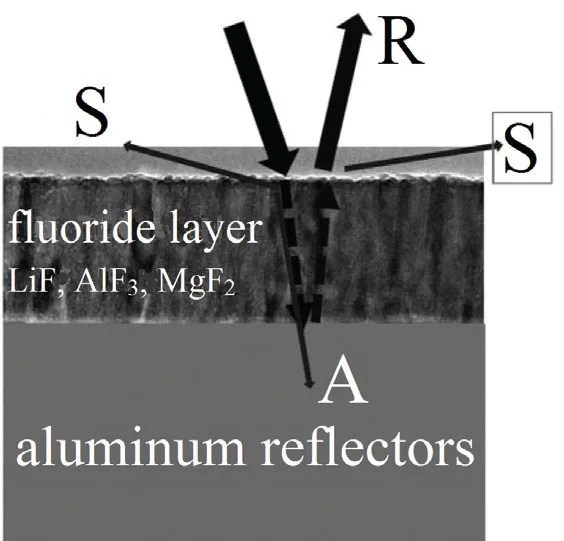

In 2016, scientists at Goddard Space Flight Center (GSFC) produced mirrors with the highest reflectance ever reported in the farultraviolet (FUV) spectral range (100-200 nm). To develop these mirrors, the team developed a new three-step physical vapor deposition process to coat aluminum mirrors with protective magnesium fluoride (MgF²) or lithium fluoride (LiF) films to protect the aluminum from naturally occurring oxidation and boost its reflectance performance in the FUV.

Impact

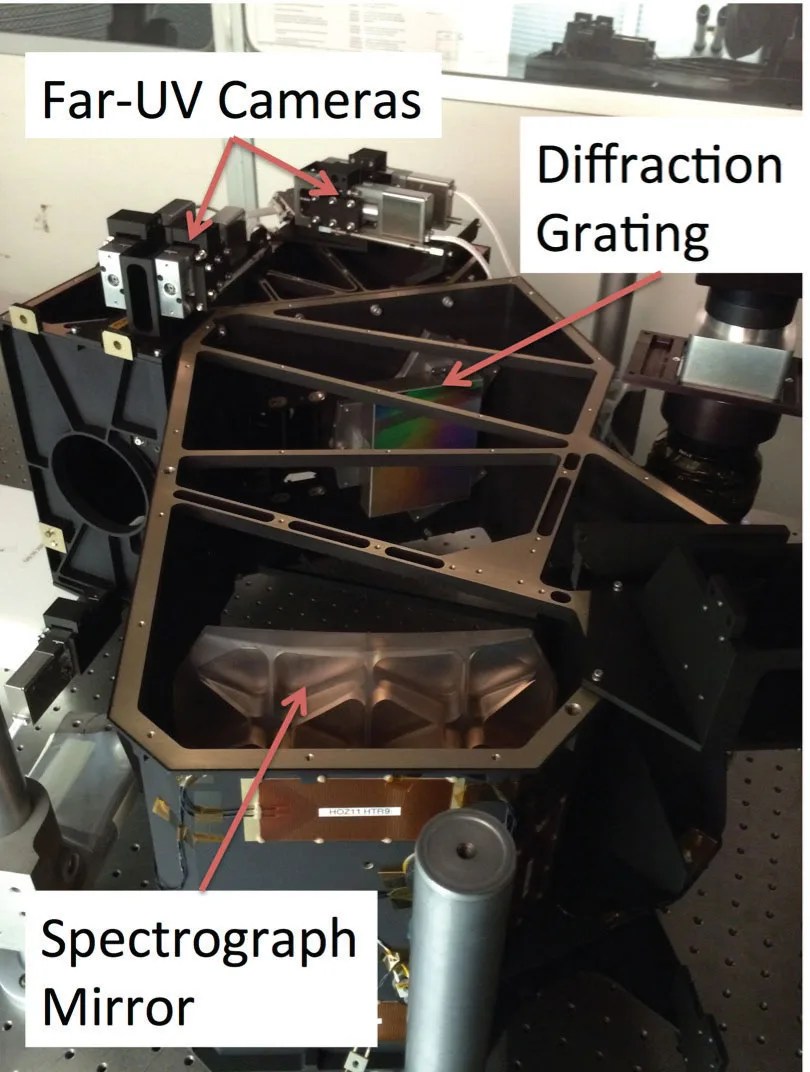

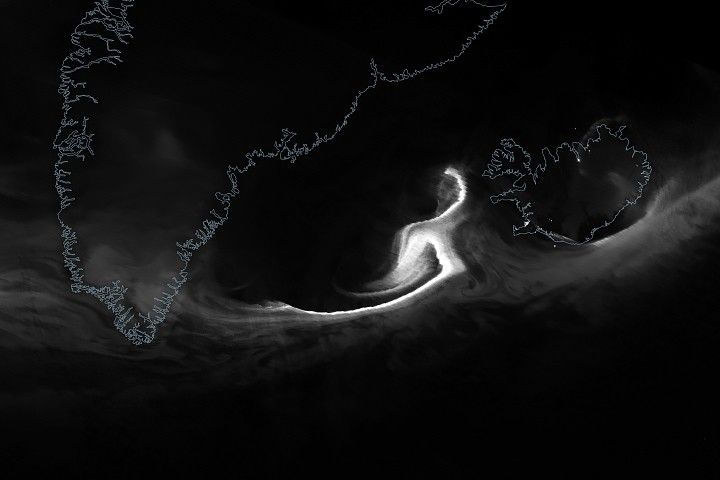

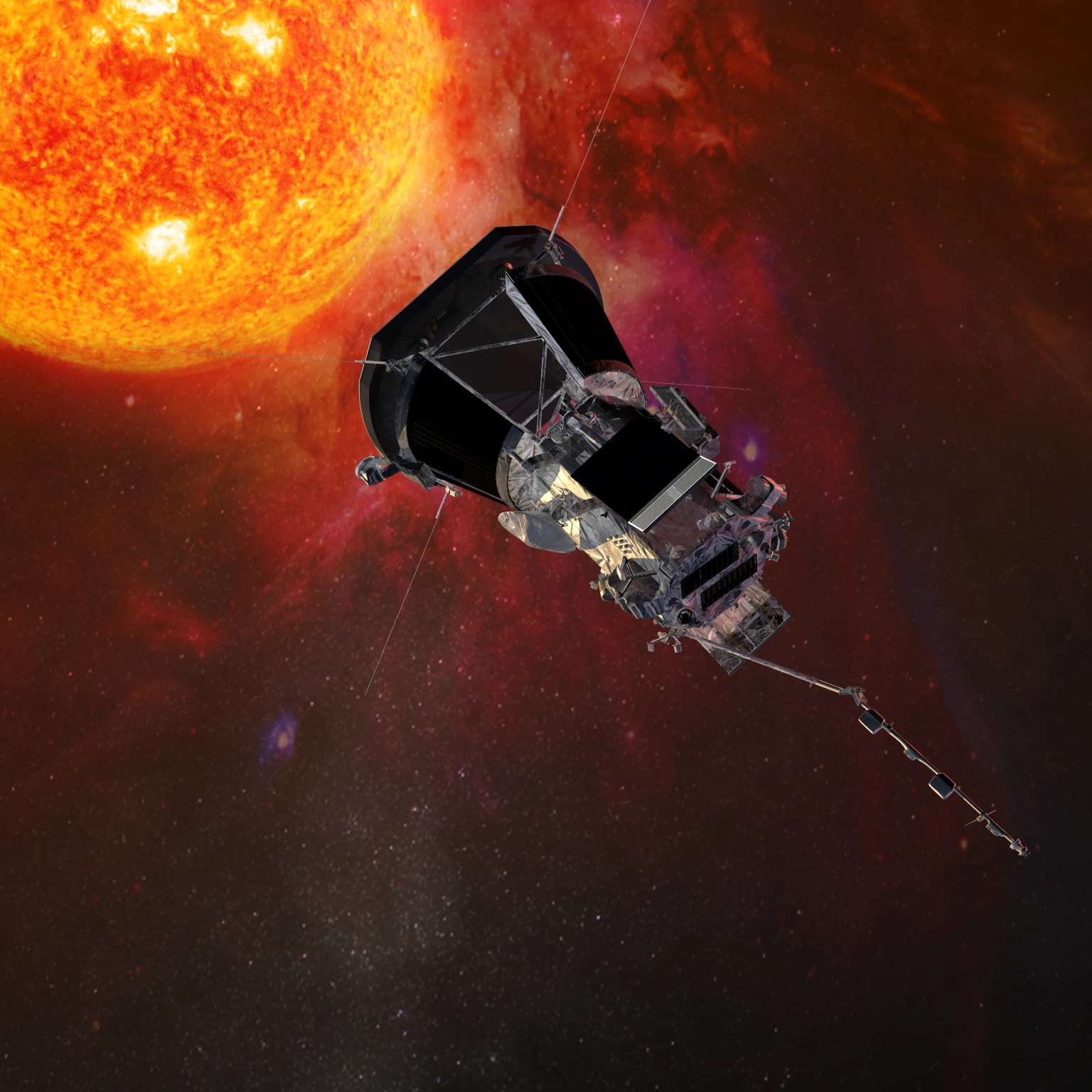

These high-reflectance coatings will enable new types of instruments (particularly in the FUV spectral region) that can provide scientists with knowledge that could impact society. For example, NASA is developing a new set of Heliophysics satellites—including the Ionospheric Connection Explorer (ICON) and the Globalscale Observations of the Limb and Disk (GOLD)—that will employ these coatings. ICON and GOLD will have the higher sensitivity required to collect data about the forces at play in the near-space environment of Earth’s upper atmosphere. These atmospheric regions are very sensitive to space weather events and space climate, and monitoring them will help scientists understand the interactions between Earth’s ionosphere and solar winds that can drive extreme weather systems. In addition, these observations will enable researchers to understand disturbances that can lead to severe interference with communications and Global Positioning System (GPS) signals.

Status and Future Plans

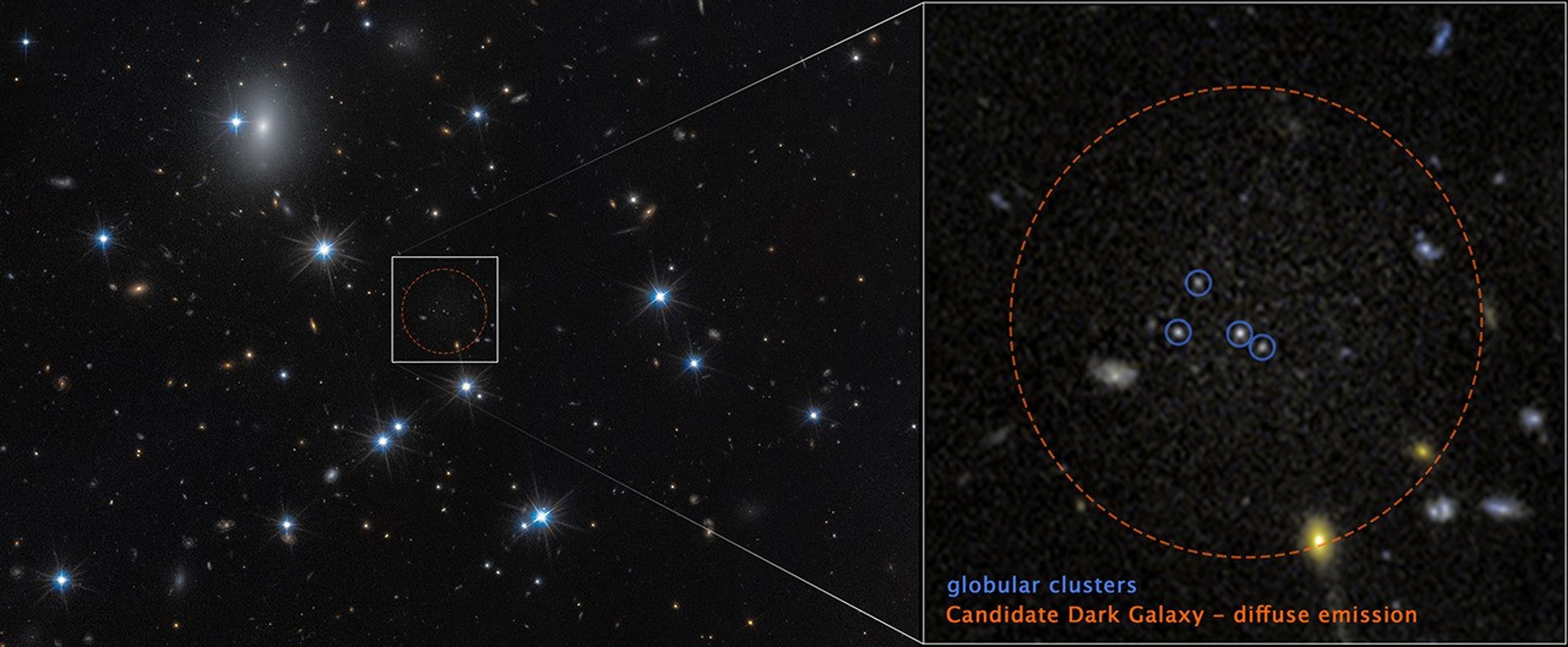

In 2016, NASA fully validated these protective coatings to ensure that they provide over 90% reflectance in the 133.6-154.5 nm range for the ICON and GOLD projects. The team is also investigating additional new types of fluoride coatings that can be used to protect aluminum to meet requirements of next-generation NASA observatories, such as the Large Ultraviolet/Optical/ Infrared (LUVOIR) surveyor.

Sponsoring Organization

SMD previously supported development of these new coating technologies through an SAT grant and currently sponsors this work via the APRA program. The technology lead is Manuel Quijada at NASA GSFC.