PROJECT

Predictive Thermal Control (PTC) project

SNAPSHOT

Active thermal control technology helps enable large ultra-stable telescopes needed to detect and characterize Earth-like planets around other stars.

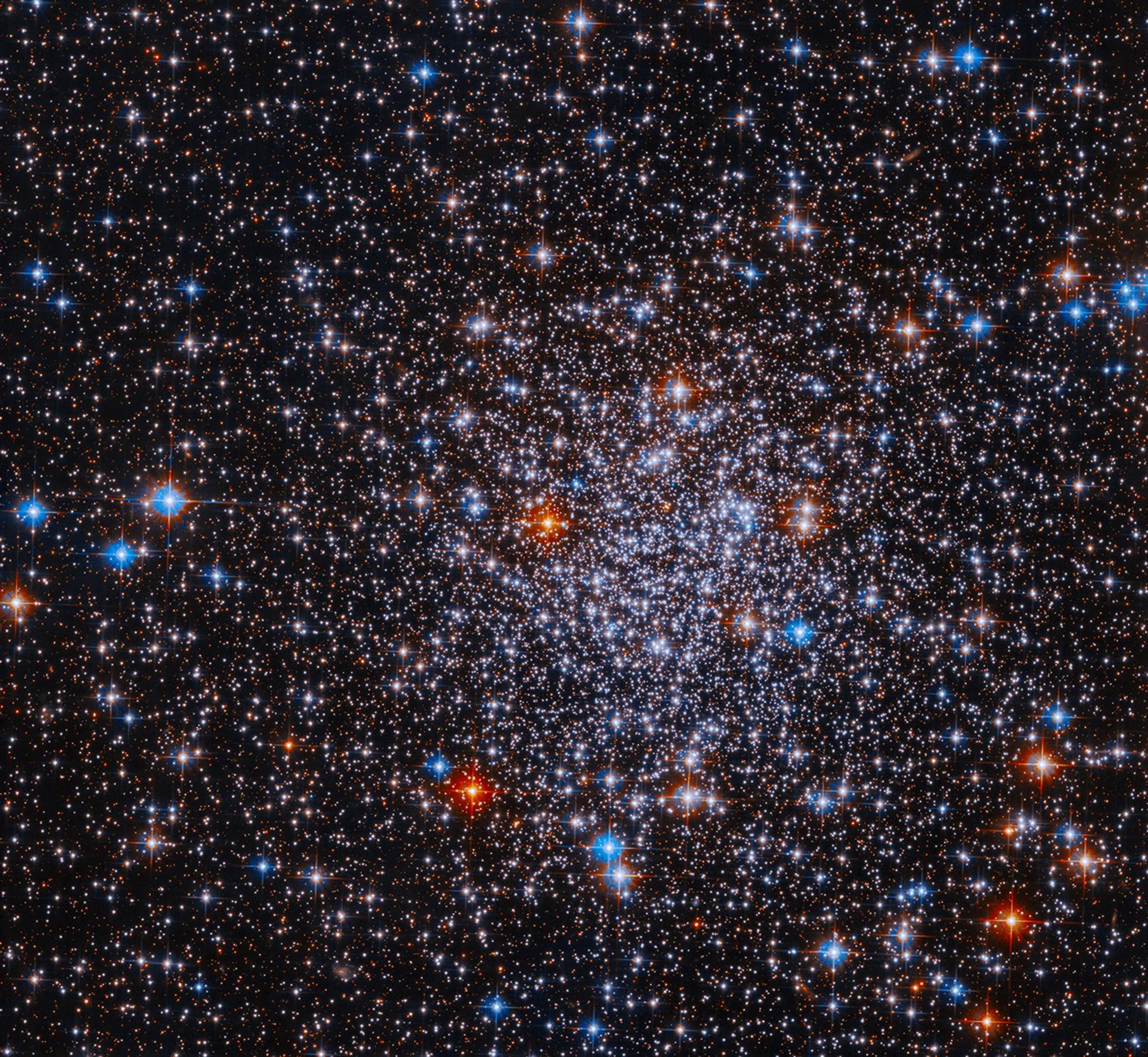

“Are we alone in the universe?” may be one of the most compelling questions of our generation. Direct imaging of planetary systems around other stars to detect and characterize Earth-like planets that could sustain life requires telescopes that are larger and more stable than any previous telescope. To respond to this challenge, NASA has been developing technologies to achieve ultra-stable telescopes since 2011.

Because an Earth-like planet is 10 billion times fainter than its star, it is necessary to block nearly all of the star’s light before we can see the planet. One way to block this light is with a coronagraph. But, any instability in the telescope – such as misalignment between the mirrors or a change in the mirror’s shape – will allow the starlight to “leak” through the coronagraph. The resulting glare will “hide” the planet. To detect an Earth-like planet with a coronagraph requires a telescope whose optical quality is stable to better than 10 picometers per 10 minutes – which is about 1 million times smaller than the width of a human hair.

According to NASA Predictive Thermal Control (PTC) project lead, Dr. Stahl, “Picometers are very small, and measuring telescope stability to picometer levels is virtually impossible. Therefore, to predict on-orbit performance we perform STOP analysis – we model a telescope’s Structural Thermal Optical Performance based on its measurable physical properties.”

For example, the stability of a telescope depends on the material properties of its mirrors and structure and the thermal changes it experiences. An object’s coefficient of thermal expansion (CTE) describes how its dimensions change as the temperature changes. The lower the CTE, the smaller the change. The mirrors in optical wavelength space telescopes such as the Hubble Space Telescope, the Kepler Mission, and the upcoming Roman Space Telescope are made from materials with ultra-low CTE. These materials have CTEs that vary by less than 5 parts-per-billion per degree Kelvin (5 ppb/K). Thus, to achieve the 10 picometer stability required to enable detection of Earth-like planets, a telescope’s mirrors must have a temperature stability of less than 2 milli-K (mK).

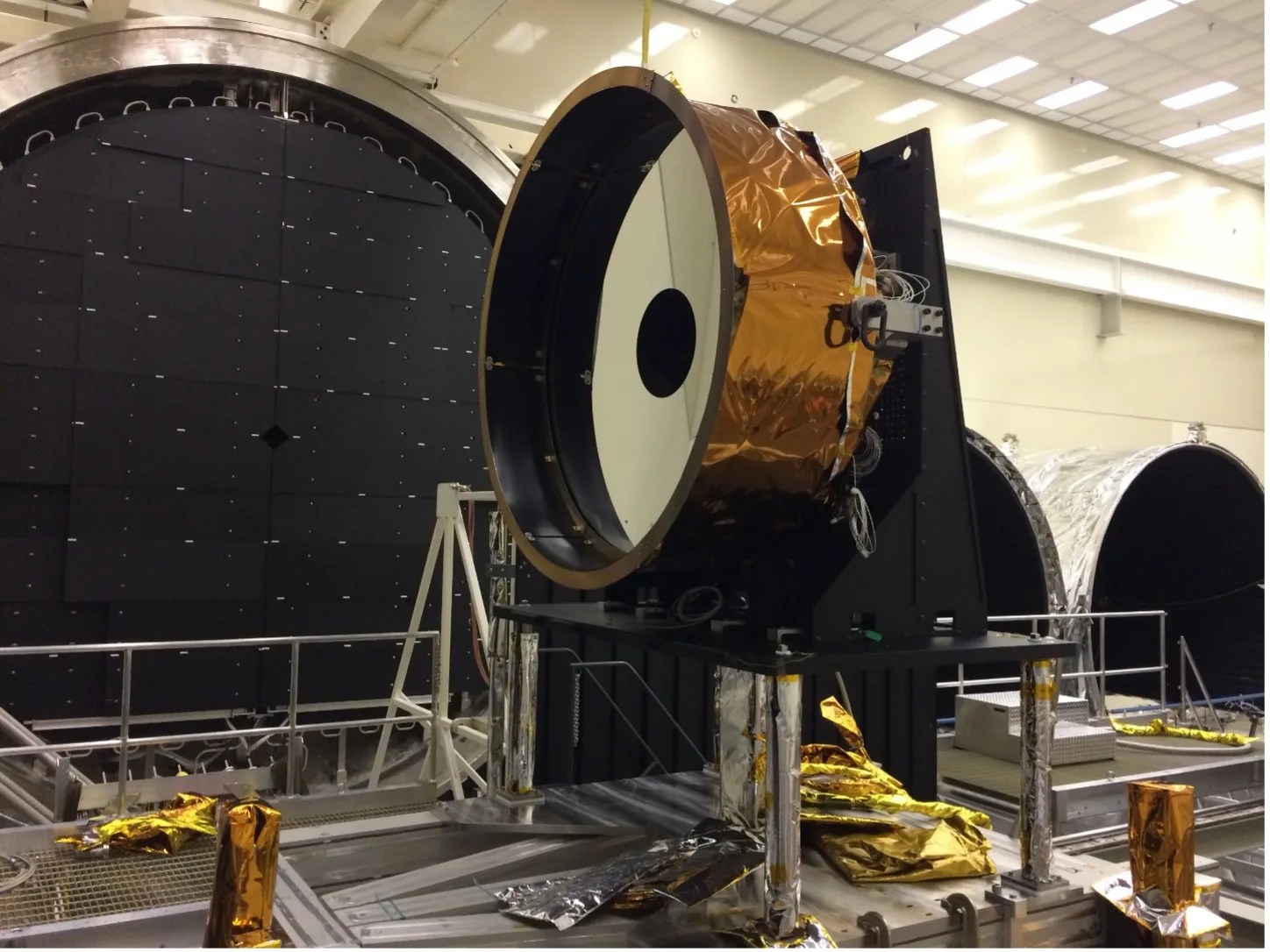

The PTC project team at NASA’s Marshall Space Flight Center (MSFC) has demonstrated technology to enable ultra-stable thermal control in large space telescopes. MSFC and its industrial partner L3Harris of Rochester, NY designed, built, and integrated a 25-zone active thermal control system with a 1.5-meter Ultra-Low Expansion (ULE©) glass mirror.

When tested in a space like thermal-vacuum environment at the MSFC X-Ray and Cryogenic Facility (XRCF), the system was able to correct thermal gradients in the mirror with an accuracy of 2K and maintain that correction with a stability of 2mK. In addition to correcting for thermal gradients, it was possible to use the zonal-thermal system to correct small mirror surface errors with a correctability of 1 nm/K peak-to-valley.

According to Dr. Stahl, “The purpose of technology development is to anticipate and solve problems to enable missions before a mission knows that it has a need. And, it is satisfying when a developed technology enables or enhances a mission.”

Since 2011, NASA’s Astrophysics Division has invested in mechanical and thermal technology to design, build and control ultra-stable telescopes. Technologies developed by PTC and its precursor study – Advanced Mirror Technology Development (AMTD) – are under consideration for the Roman Space Telescope as well as several potential future missions.

PROJECT LEAD

Dr. H. Philip Stahl and Thomas Brooks, NASA Marshall Space Flight Center (MSFC)

SPONSORING ORGANIZATION

Astrophysics Division Strategic Astrophysics Technology (SAT) Program