Specialized test rig determines how new technologies fare in extreme conditions

PROJECT:

Hot Operating Temperature Technology (HOTTech) Program; NASA Glenn Extreme Environment Rig (GEER)

SNAPSHOT:

Projects in NASA’s HOTTech Program are developing technologies that will operate on the surface of Venus for at least 60 days. Since previous Venus landers have only survived for several hours, long-duration operation represents a paradigm shift in landed spacecraft technology. The GEER chamber at NASA Glenn Research Center simulates Venus conditions and acts as a testbed for materials, electronics, sensors, and power technologies for future long-duration exploration.

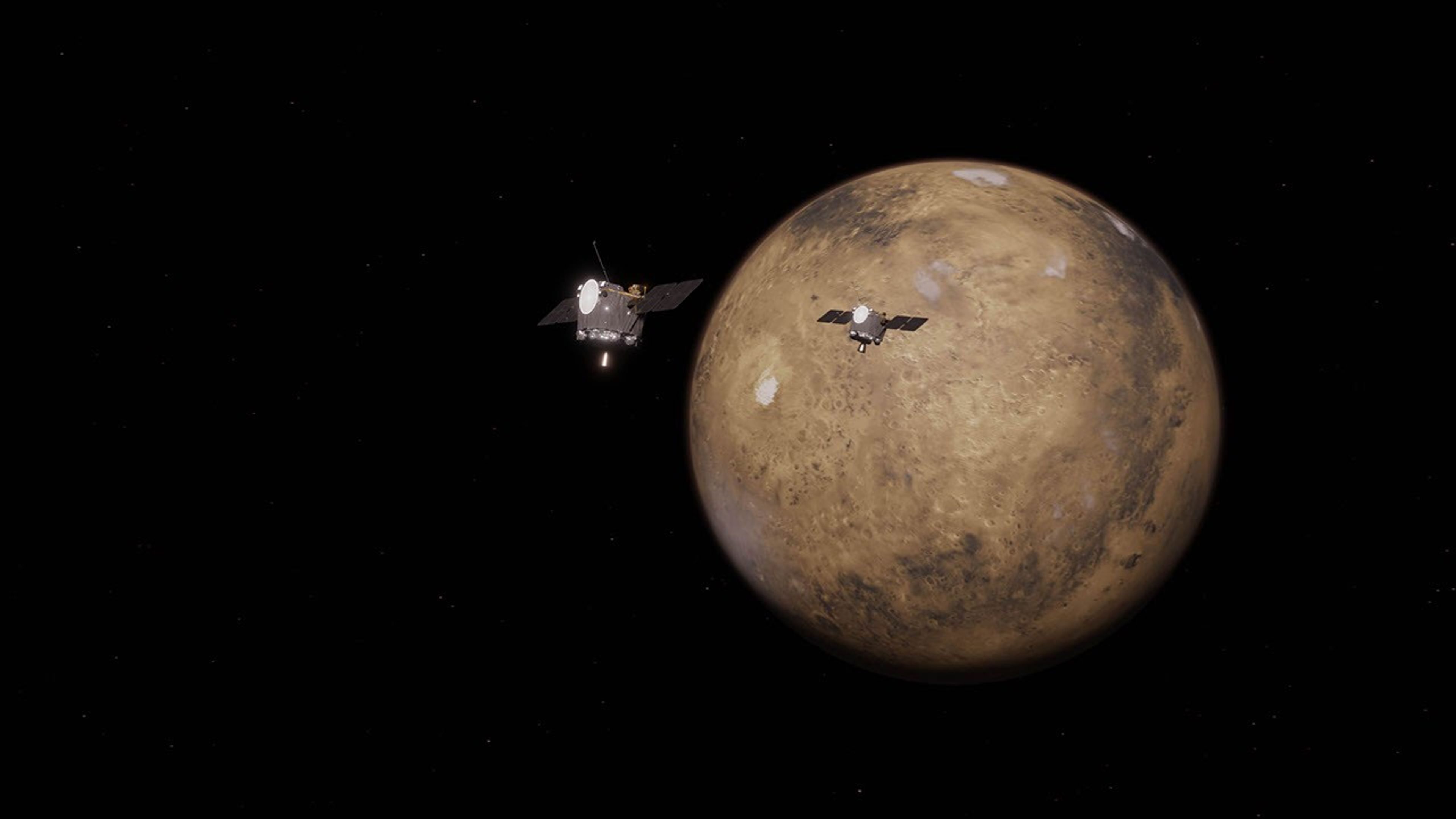

As far as solar system exploration goes, the surface of Venus is an inhospitable place for technology. The average temperature is almost 900°F, high enough to melt metals like lead; the atmospheric pressure is over 90 times that of Earth; and the atmosphere contains highly corrosive chemicals. Previous Venus landers subjected to these harsh environmental conditions have only survived for several hours. To overcome this challenge, the HOTTech Program is developing core technologies including electronics, batteries, power systems, and actuators that will be able to operate on the Venus surface for at least 60 days.

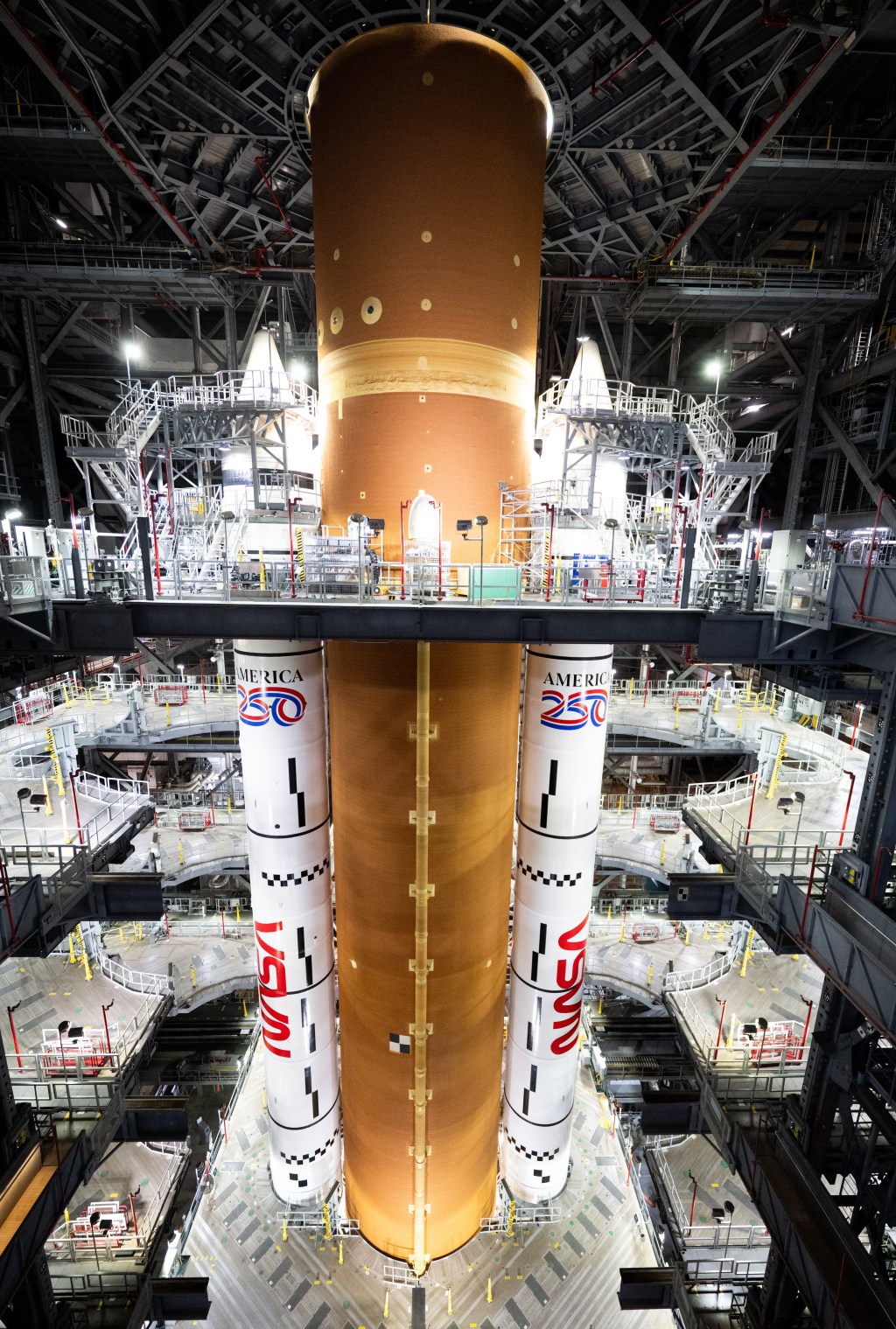

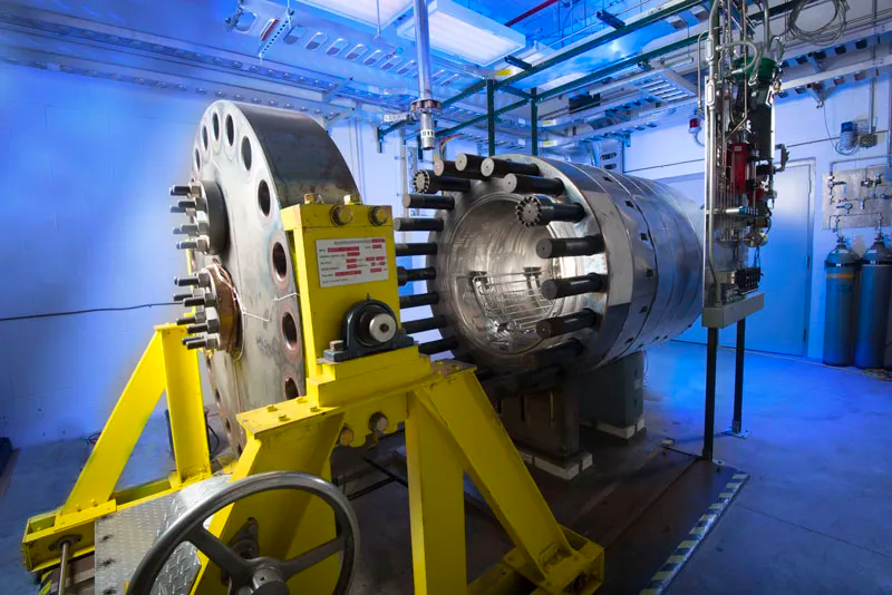

The teams working on these technologies have been iteratively building and testing in laboratories throughout the US over the last several years, but eventually the big question is: How would these technologies fare on Venus? Enter the Glenn Extreme Environment Rig (GEER), a nearly 20-ton chamber at the NASA Glenn Research Center designed to simulate the conditions on the surface of Venus. The chamber is massive to safely contain the Venus pressure. The GEER end cap, which slides opens on railroad-like rails to enable set up of experiments, is subject to two million pounds of force as the Venus surface pressure is simulated. Heaters keep the chamber and everything inside at the extreme temperature of almost 900°F. Furthermore, GEER can insert and monitor corrosive gases in the chamber and ‘boost’ them as needed to match conditions expected on the Venus surface (these gases may react with the technologies being tested!). Finally, the GEER team has incorporated electrical feedthroughs to allow power and electrical signals to be transferred between the HOTTech technology inside the chamber and external test equipment.

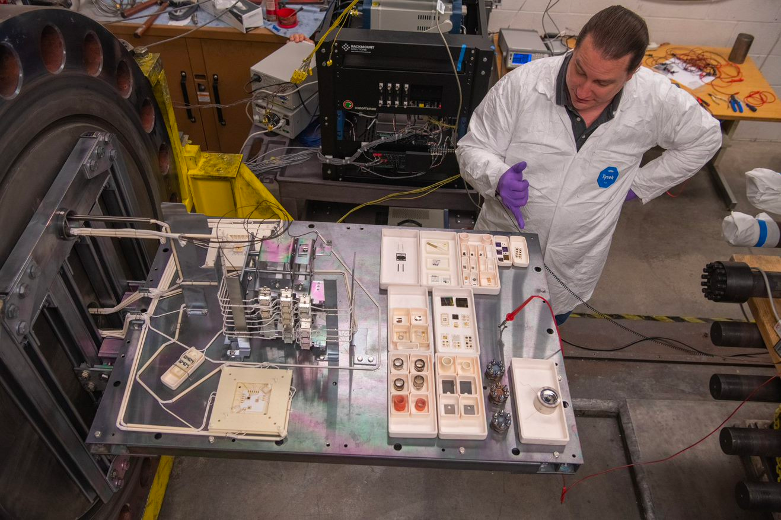

Several HOTTech project teams formed a community of practice to collaborate with each other and the GEER team to improve and optimize their technologies. The goal is to eventually combine successful individual components into increasingly capable systems. The technologies listed below were recently tested together in GEER to learn how they might fare during long-term operations on Venus:

| HOTTech program technologies recently evaluated in GEER | |

| Principal Investigator/Institution | Technology |

| Jitendra Kumar/University of Dayton | Battery technology |

| Darby Makel/Makel Engineering, Inc. | Silicon carbide electronics for chemical sensors |

| Alan Mantooth/University of Arkansas | Electronics packaging |

| Robert Nemanich/Arizona State University | Diamond electronics |

| Phil Neudeck/NASA GRC | Silicon carbide RAM Memory |

| Leora Peltz/Boeing | Field emission electronics |

| Alex Rattner/Penn State University | Seals for power production |

| Debbie Senesky/Stanford University | Gallium nitride clock circuits |

| Yuji Zhao/Arizona State University | Gallium nitride electronics |

The GEER test of these technologies ran from December 2022 through February 2023. Although the technologists are still performing post-test analyses to evaluate how their technologies performed, some encouraging initial results have already been noted.

Gaskets are critical components that seal the various mechanical and electrical systems on a spacecraft or lander, preventing the ingress of dust, gas, and other contaminants. While developing a power system for a future Venus lander, the Penn State team identified vermiculite as a potential gasket material capable of surviving the extreme Venusian conditions. “Vermiculite is a mineral with excellent thermal stability, a low coefficient of thermal expansion, and a great resistance to most corrosive environments” said Dr. Christopher J. Greer, Assistant Research Professor Mechanical Engineering, Penn State University. The GEER tests determined the ability of this vermiculite sealing material to hold back the high pressure and temperature and withstand the corrosive conditions on Venus.

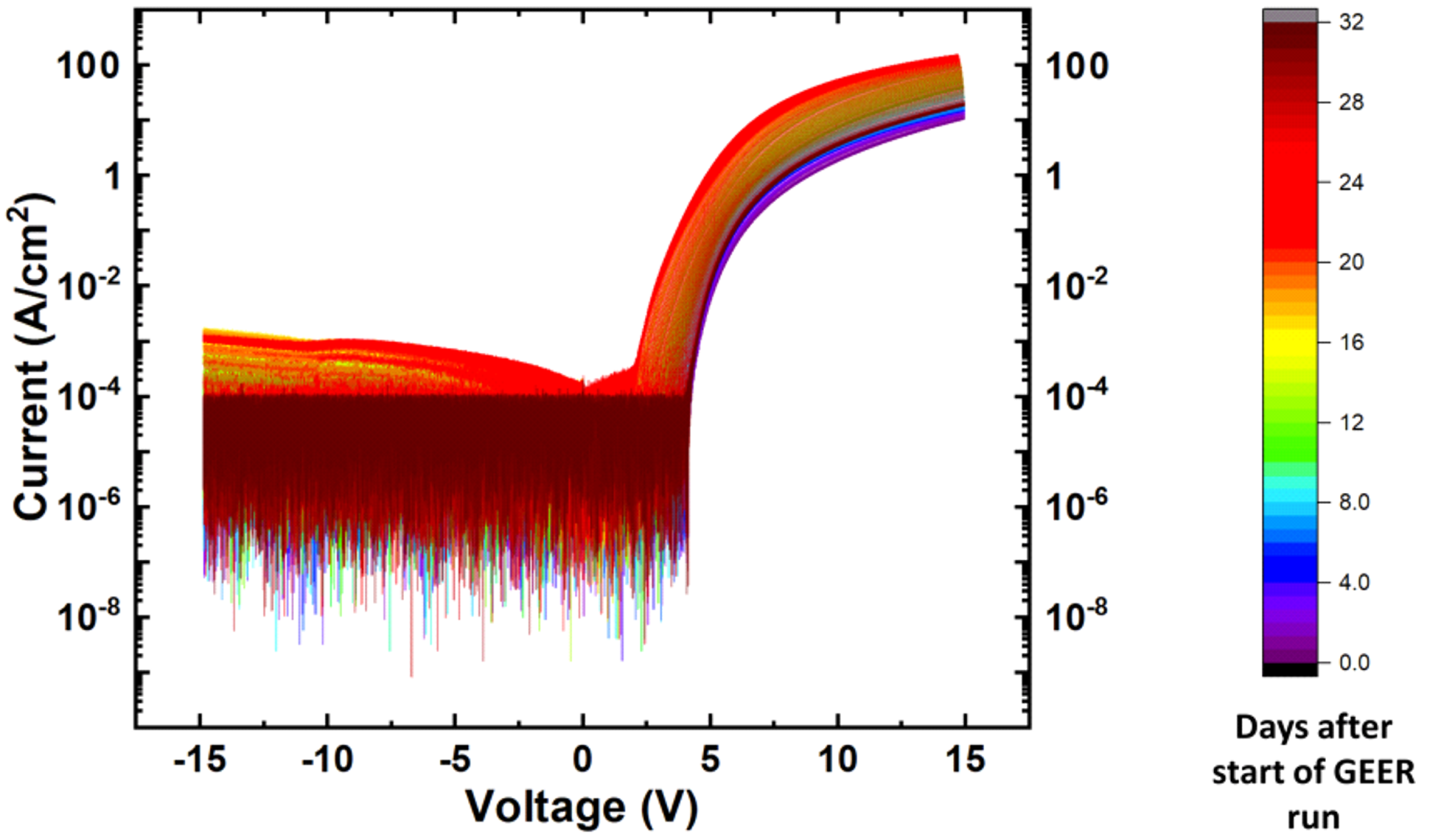

In a collaborative effort, three different groups tested electronic devices packaged by a fourth group in this recent GEER test. One of those devices was a diamond diode provided by Dr. Nemanich, a member of the Arizona State University team. He explains “Each hour, the computer-controlled system turned the diamond diode on and recorded the current density (vs. voltage) in the forward and reverse directions. The figure below presents a composite plot of all measurements during the 30 days. Throughout the test, the diode showed a high rectification ratio (forward vs reverse current density), which is consistent with the theoretical simulations.” This GEER test represents the first demonstration of diamond-based electronics operating in simulated Venus surface conditions for an extended time, and provides a foundation for a new type of electronics for future missions

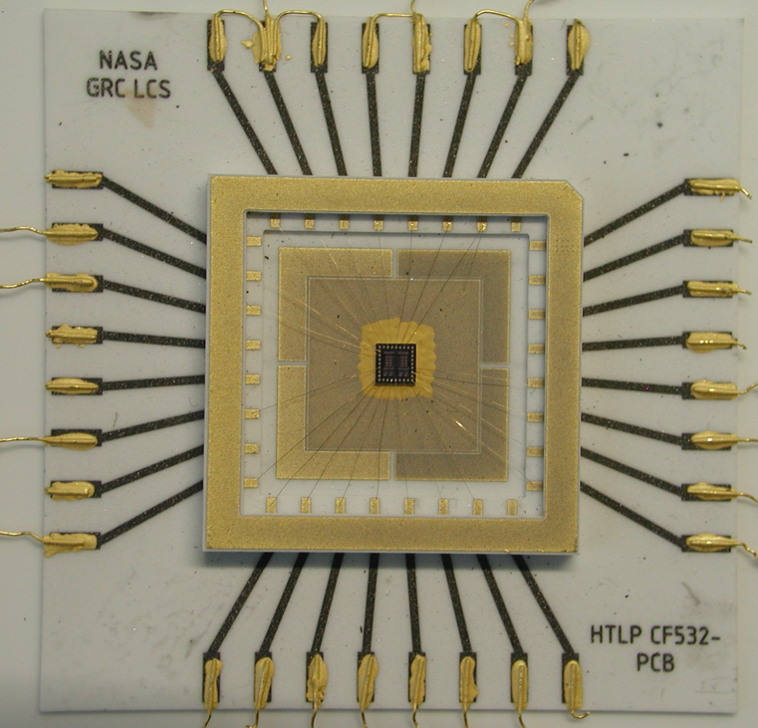

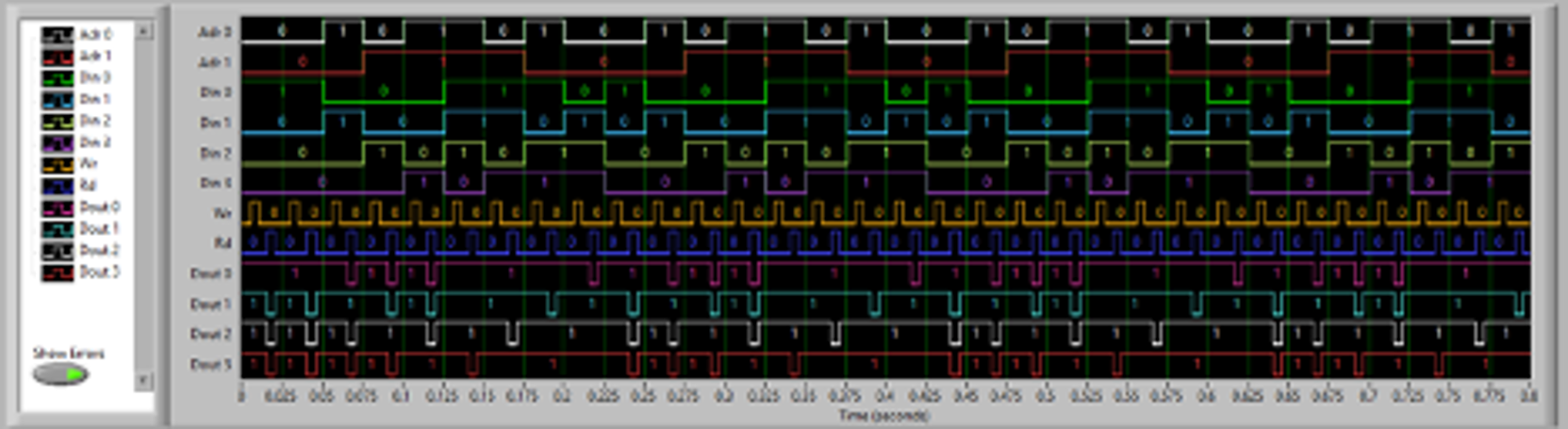

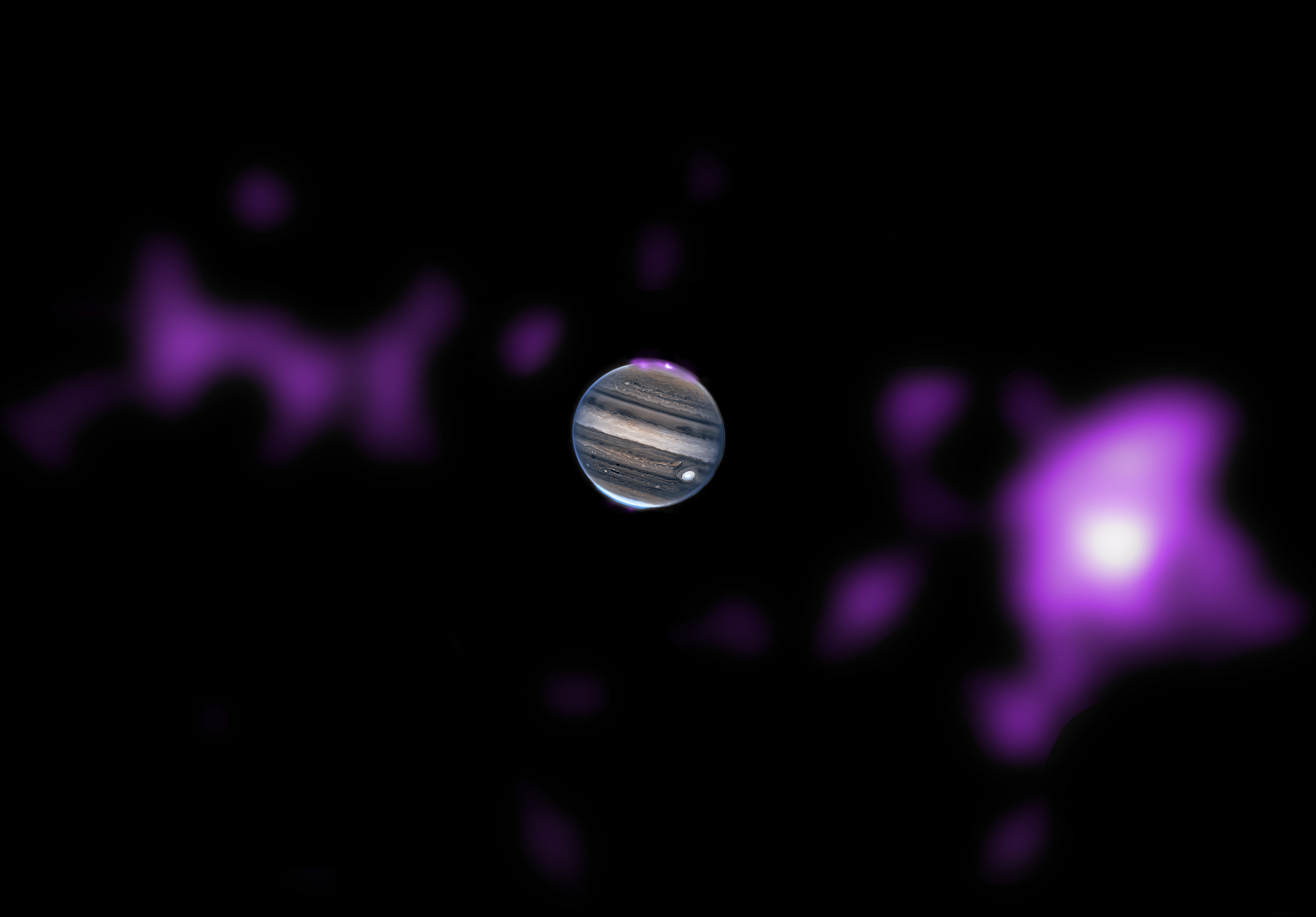

A notable “first” achieved in the GEER test was the successful operation of electronic memory, which allows scientific data to be stored until it can be transmitted using silicon carbide (SiC) electronics. The picture below shows the pristine condition of the memory chip and packaging after the GEER test was completed, as well as a snapshot of the electrical performance during the test. Dr. Phil Neudeck, NASA GRC, remarked, “Even though this early prototype chip is just 16 bits, it nevertheless represents the first random access memory ever to demonstrate successful operation for days while exposed to the insanely harsh temperature, pressure, and reactive chemical environment found on the Venus surface. The chip outlasted the Venus environment test duration. Such capability represents another step in the march towards opening the Venus surface to the kind of prolonged robotic exploration that has proven so scientifically fruitful on the surface of Mars.”

Other technologies were also tested in this latest GEER run. Results are still being analyzed and will be the subject of future presentations and publications. As a whole, a wide range of technologies and materials of differing levels of maturity were, in some cases, given their first GEER-simulated Venus surface exposure. Some technologies gained a new level of demonstrated maturity, while developers of others gained valuable lessoned learned about the harsh environment on the surface of Venus. This collaborative GEER testing effort provided a foundation for future technology advancements that will enable extended missions on the surface of Venus.

PROJECT LEADS:

Dr. Michael Lienhard (GRC), PSD HOTTech program officer;Dr. Gary Hunter (GRC), HOTTech GEER coordinator; and the HOTTech Principal Investigators listed above

SPONSORING ORGANIZATION:

NASA SMD Planetary Science Division HOTTech Program