PROJECT

Phenolic Impregnated Carbon Ablator – Domestic (PICA-D) Development and PICA Capability Sustainment (PCS)

SNAPSHOT

To ensure the availability of Phenolic Impregnated Carbon Ablator (PICA) thermal protection systems (TPS) for NASA missions, the agency is developing PICA-D – an updated TPS material that uses a domestically sourced raw material, Lyocell, along with a streamlined and optimized manufacturing process.

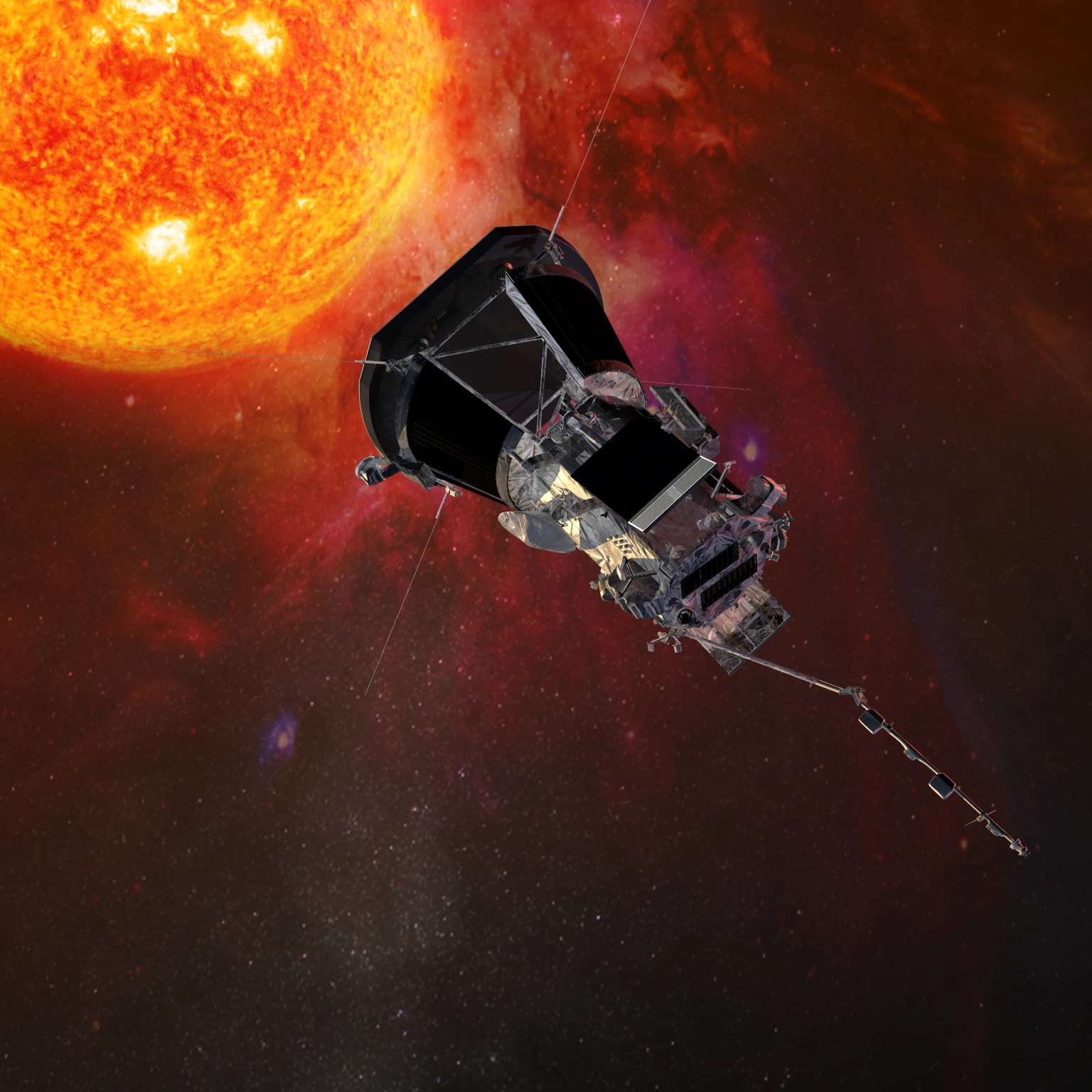

All space missions that involve atmospheric entry of a probe or science payload (lander/rover) must utilize a Thermal Protection System (TPS) to protect the payload from the extreme heat experienced during atmospheric entry. For many past and recent planetary in situ and sample return missions including Stardust; Mars Science Laboratory; the Origins, Spectral Interpretation, Resource Identification, Security-Regolith Explorer (OSIRIS-Rex); and Mars 2020; the TPS of choice has been PICA—a material system developed by the NASA Ames Research Center.

PICA is used in aeroshells—the rigid casings that help protect spacecraft from the extreme heat experienced during atmospheric entry. As a spacecraft enters a planet’s atmosphere, the PICA heat shield slowly burns off, dissipating the intense heat and protecting the vehicle in a process called ablation. PICA is currently the workhorse of TPS materials for NASA because it the lightest weight ablator capable of withstanding entry at Earth, Mars, and Titan. NASA Ames invented PICA using a rigid low-density carbon preform called FiberForm that Fiber Materials Inc. (FMI) made commercially, starting in the 1990s. At the time PICA was developed, FiberForm was primarily used as furnace insulation, but a team at NASA Ames developed PICA as a clever new application for this material.

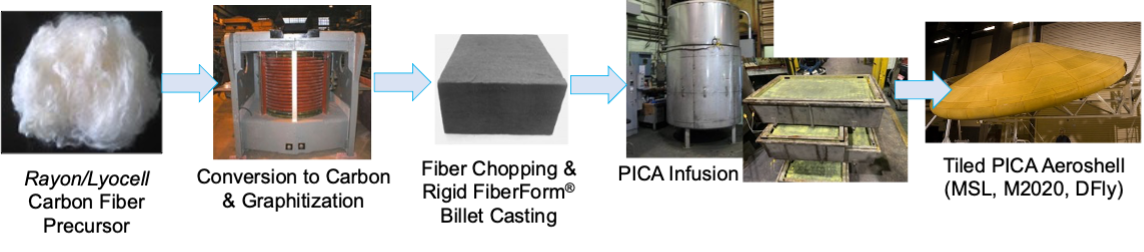

The fabrication of PICA begins with the procurement of rayon, which is derived from wood pulp cellulose and is preferred over other carbon-based materials because of its low thermal conductivity. The rayon is carbonized and cast into a rigid block called FiberForm. The FiberForm is then infused with a low-density aerogel of phenolic resin that serves as the ablative material during reentry. Completed PICA billets can then be machined into tiles and installed on an aeroshell.

NASA Ames transferred this PICA technology to FMI so that FMI could provide PICA TPS for NASA missions using industrial-scale quality assurance practices to ensure repeatable results. About five years ago, however, NASA Ames learned that the foreign entity supplying the heritage rayon utilized in PICA was halting production. In addition, FMI announced plans to discontinue the commercial manufacture of FiberForm, a necessary component of PICA. These conditions would potentially impact NASA’s upcoming Mars Sample Return (MSR) mission and the Dragonfly mission to Titan, as both missions have baselined the PICA TPS for their heatshields – it would have been devastating to lose this capability that the Nation has utilized for so many recent planetary science missions.

In early 2016, to avert disaster, NASA Ames began evaluating FiberForm and PICA utilizing a domestically sourced rayon alternative, Lyocell. Lyocell is also a cellulose-based fiber but its manufacture uses a more environmentally friendly process. Ames investigated Lyocell and initial testing showed it to be a good replacement for the heritage rayon used in PICA – thus the PICA-Domestic (PICA-D) project was established.

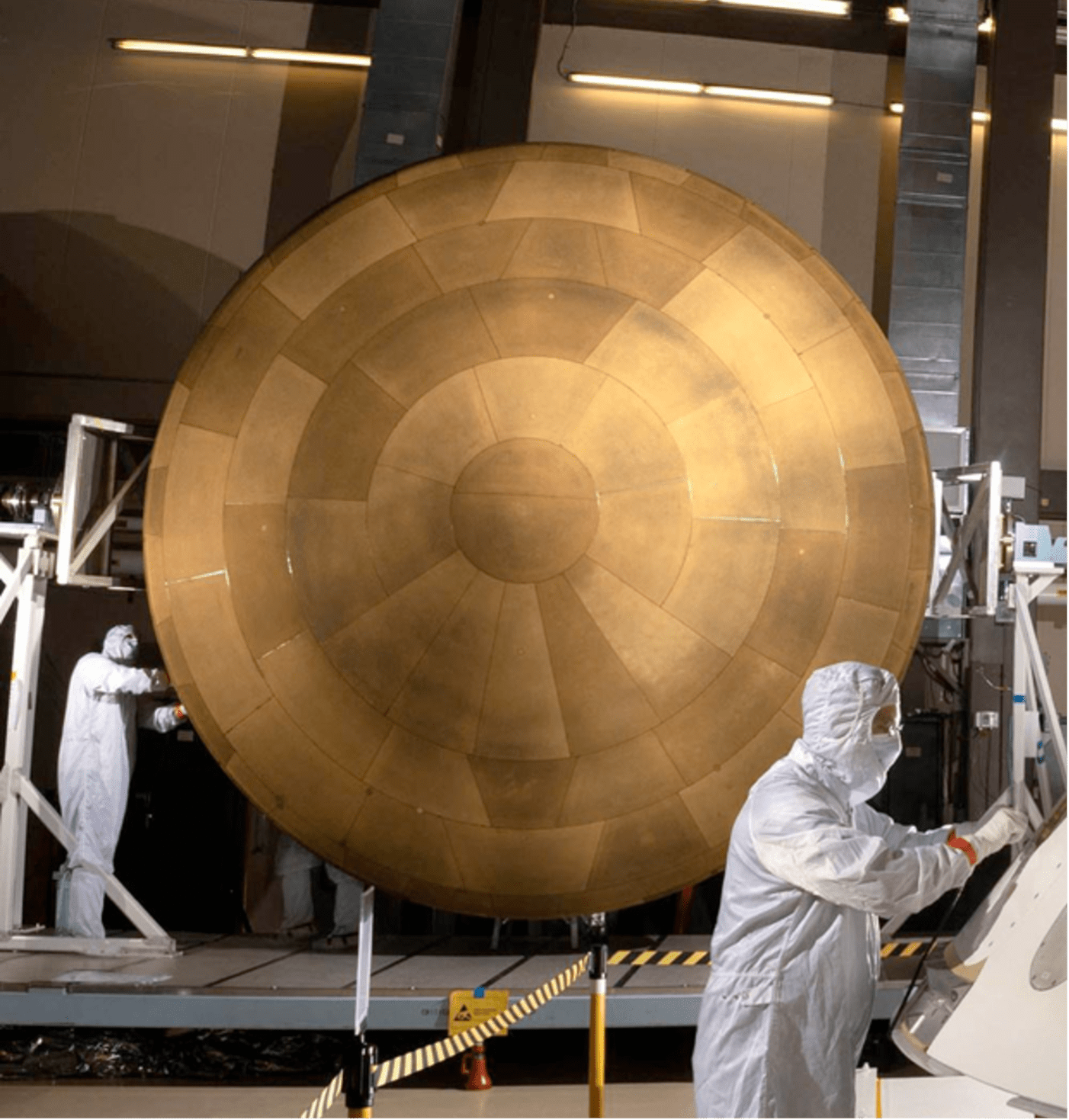

In 2017, NASA PSD tasked Ames to lead the PICA Capability Sustainment (PCS) effort to address the sustainability issue regarding FMI’s plan to discontinue FiberForm production. As part of this PCS project, NASA Ames worked with FMI to upgrade the company’s facilities to manufacture a higher quality aerospace grade of FiberForm using the new Lyocell fiber. From FY18 to FY21, further efforts were undertaken to characterize and qualify the capability of PICA-D as a “drop-in” replacement for heritage rayon-based PICA, which would allow missions to depend on and design with PICA-D without having to address further sustainability risks.

The PICA-D and PCS projects are concluding at the end of calendar year 2021 and Ames is pleased to announce that the new equipment at FMI is yielding flight-quality PICA-D TPS. To date, FMI has manufactured 22 billets of PICA-D that completed flight Lot Acceptance Testing (LAT). Results from these tests have been compared to the PICA LAT results from the MSL and Mars 2020 efforts; PICA-D LAT results are comparable to those for the heritage PICA and are within the expected scatter of the MSL and M2020 data sets. These results indicate that updates to thermal and/or structural performance models are not required for the upcoming Dragonfly and MSR missions to use PICA-D.

In addition to material property measurements, recent thermal response arcjet testing of PICA-D models was completed in October 2021. PICA-D models were tested alongside Mars 2020 PICA and all results indicate that the PICA-D material performed identically to the Mars 2020-era PICA TPS.

In support of NASA’s upcoming Dragonfly and Mars Sample Return Lander missions, FMI will be producing 107 billets of PICA-D for the Dragonfly and 112 billets of PICA-D for the Mars Sample Return Lander continuously through the end of calendar year 2023. Upgrades to the facilities at FMI have vastly streamlined the PICA-D process and promise to provide sustainability of the PICA family of materials for many years to come.

This outcome is exciting because Dragonfly and Mars Sample Return can’t be done without PICA-D material and we expect that for decades to come many exciting NASA missions will need the PICA-D TPS to enable successful atmospheric entries of probes, landers, and sample return capsules.

PROJECT LEAD

Dr. Matthew Gasch, NASA Ames Research Center