About Webb's Sunshield

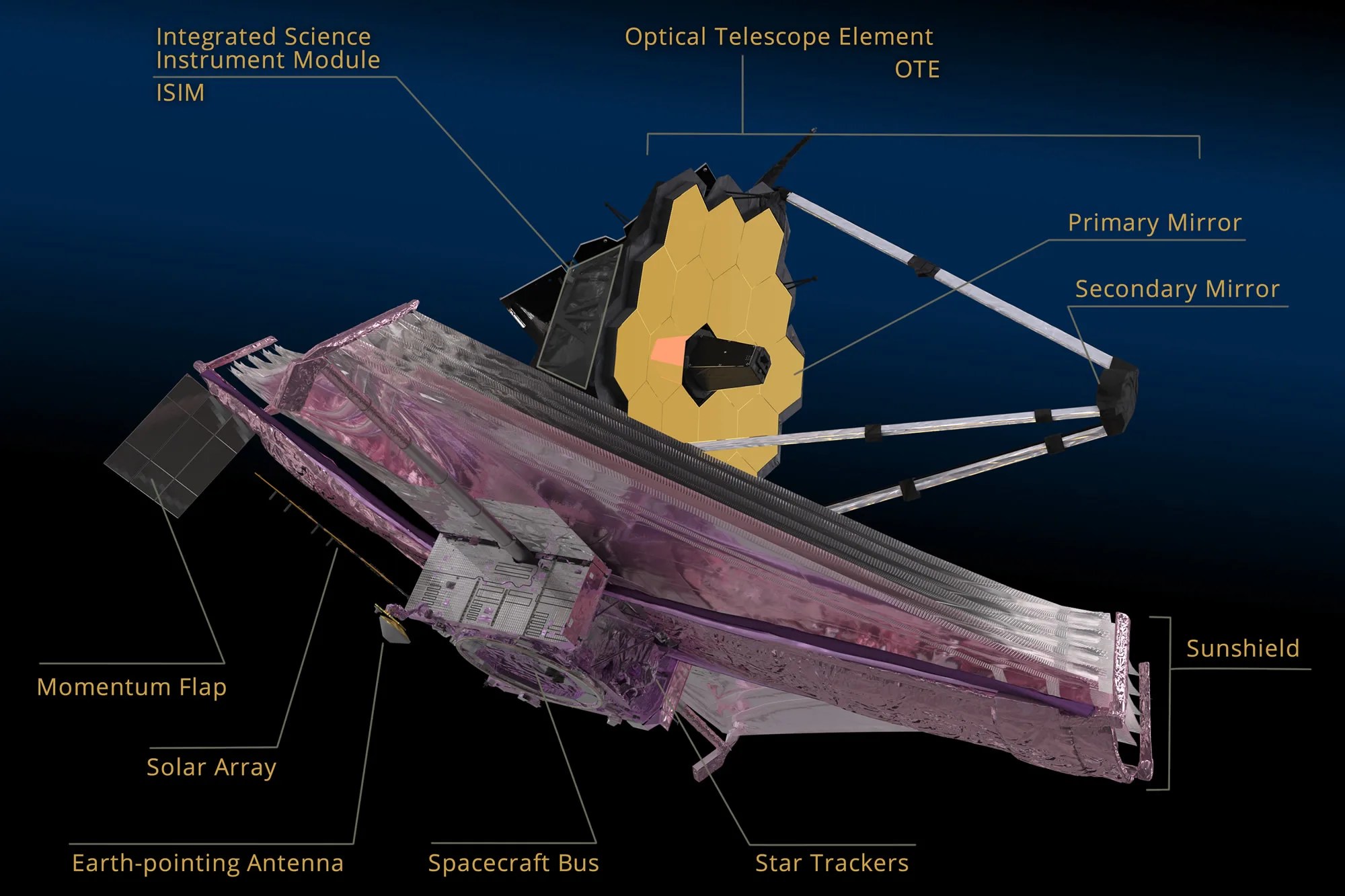

Webb is an infrared telescope, its mirrors and sensors need to be kept at extremely cold temperatures to detect faint heat signals from distant objects in the universe. The sunshield protects the telescope from external sources of light and heat as well as from heat emitted by the observatory itself.

Quick Facts

Why a Sunshield?

The James Webb Space Telescope's primary science comes from infrared light, which is essentially heat energy. To detect the extremely faint heat signals of astronomical objects that are incredibly far away, the telescope itself has to be very cold and stable. This means we not only have to protect Webb from external sources of light and heat (like the sun and the earth), but we also have to make all the telescope elements themselves very cold so they don't emit their own heat energy that could swamp the sensitive instruments. The temperature also must be kept constant so that materials aren't shrinking and expanding, which would throw off the precise alignment of the optics.

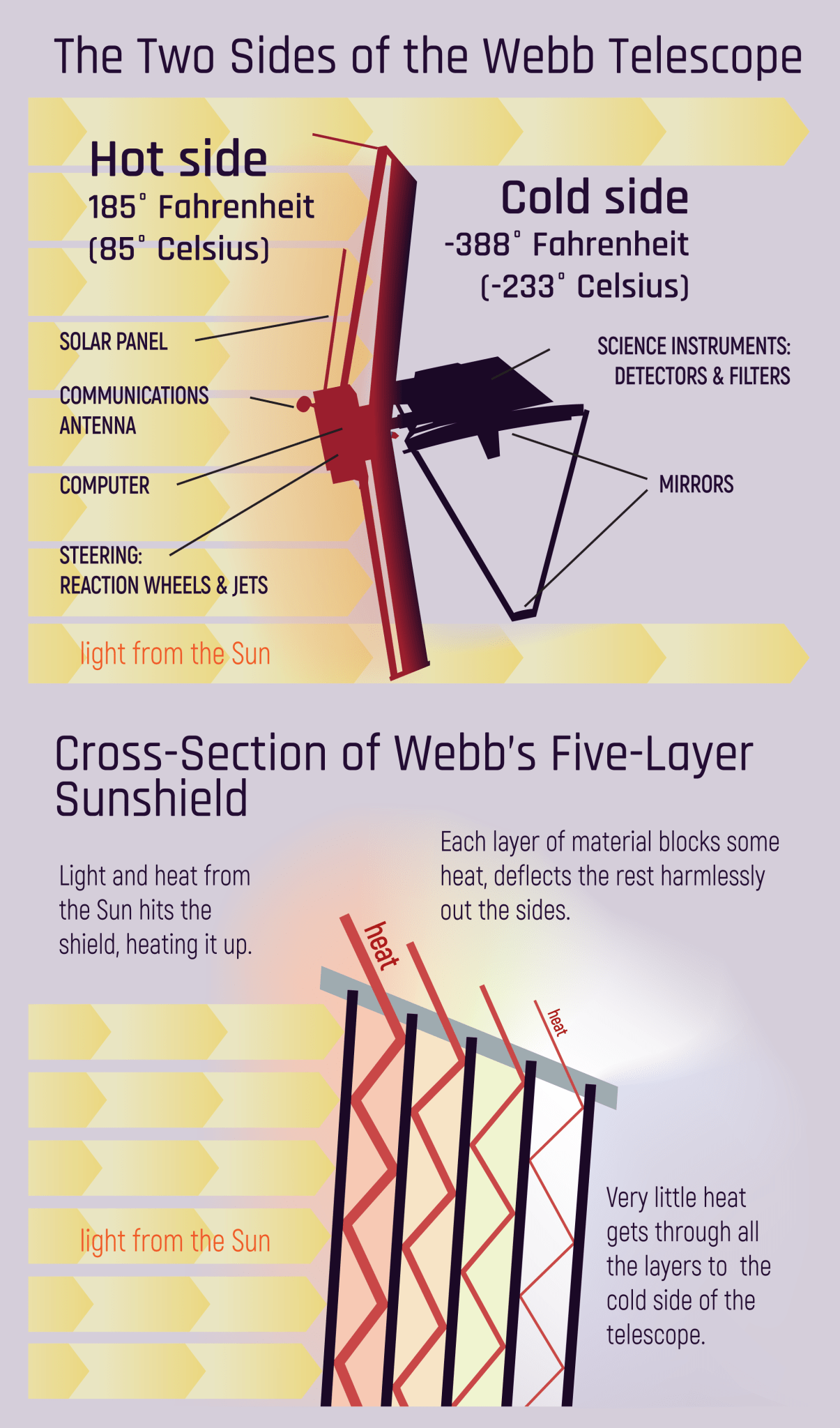

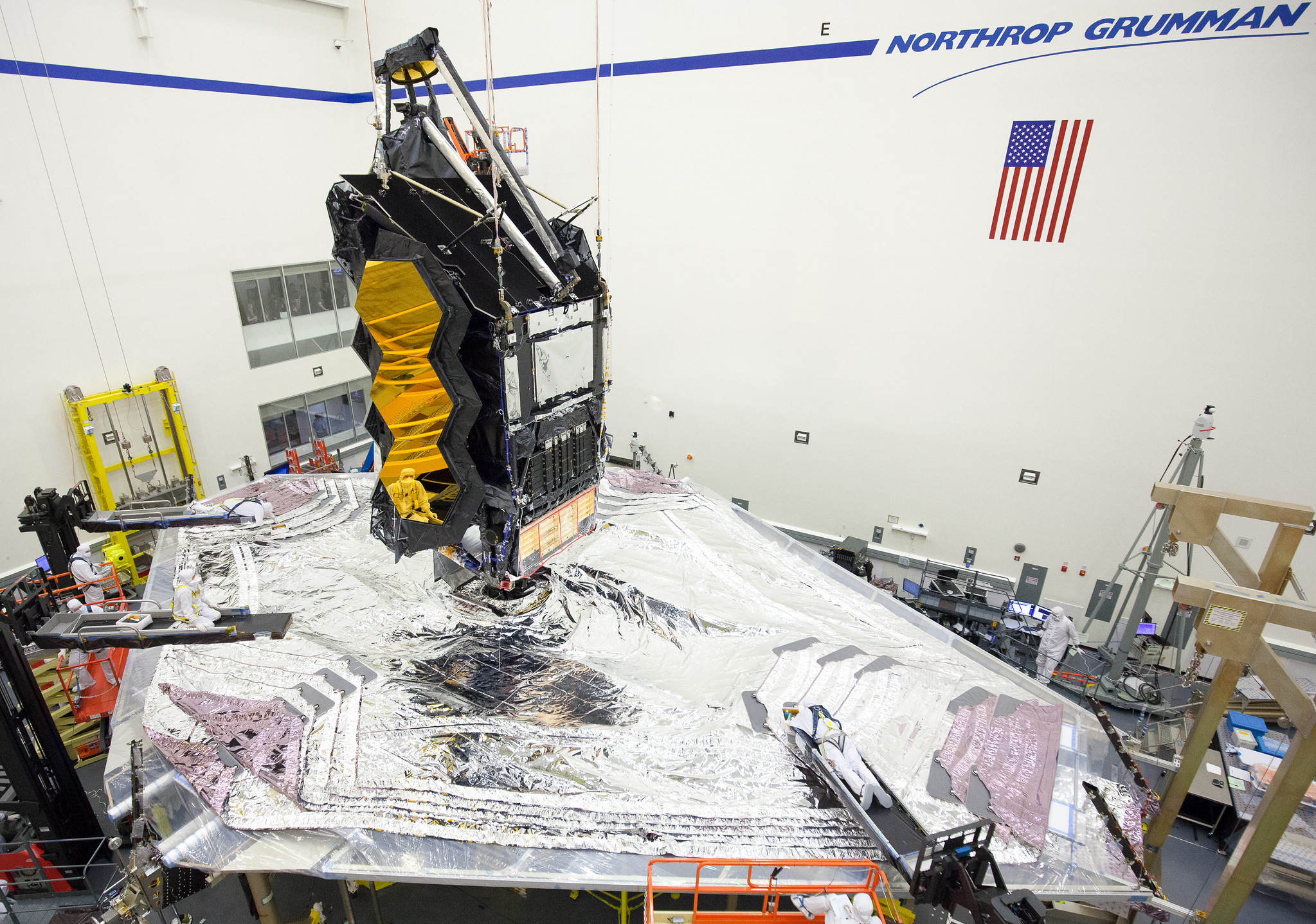

To protect the telescope from external sources of light and heat (like the Sun, Earth, and Moon) as well as from heat emitted by the observatory itself, Webb's 5-layer, tennis court-sized sunshield reduces the temperature between the hot and cold side of the spacecraft by approximately 570° Fahrenheit (299° Celsius) across its 5 layers. The actual dimensions: 21.197 m x 14.162 m (69.5 ft x 46.5 ft).

Cooling to Operating Temperatures

The sunshield separates the observatory into a warm, sun-facing side ( with maximum temperature modelled at the outermost layer of 383K or approximately 230 degrees F), and a cold side (with the coldest layer having a modeled minimum temp of 36K or around -394 degrees F). The telescope requires temperatures under 50K (~-370F) to operate.

After launch and deployment, the sunshield allowed the telescope to cool down to required operating temperatures and remain stable below 50 Kelvin (-370°F, or -223°C) by passively radiating Webb's heat into space. The near-infrared instruments (NIRCam, NIRSpec, FGS/NIRISS) work at about 39 K (-389°F, -234°C) through a passive cooling system. The mid-infrared instrument (MIRI) requires colder temperatures that require reaching a temperature of 7 K (-447°F, -266°C), using a helium refrigerator, or cryocooler system.

In addition to providing a cold environment, the sunshield provides a thermally stable environment. This is essential to maintaining proper alignment of the primary mirror segments as the telescope changes its orientation to the Sun.

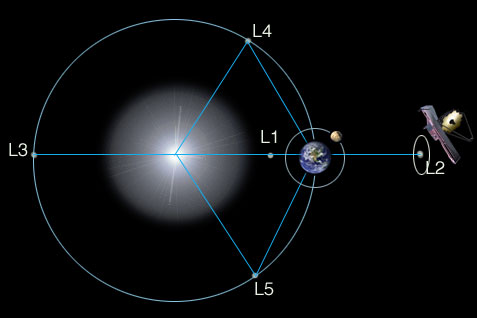

Sunshield Position in Orbit

Webb's sunshield is always oriented between the Sun/Earth/Moon and the telescope in its orbit around L2 to supply the required cold and thermally stable environment in which Webb operates .

Webb's OrbitWhy Five Layers?

Why does the sunshield have five layers instead of just a single thick one? Each successive layer of the sunshield is cooler than the one below. The heat radiates out from between the layers, and the vacuum between the layers is a very good insulator. One big thick sunshield would conduct the heat from the bottom to the top more than five layers separated by vacuum.

According to Keith Parrish (former Webb Observatory Manager and former Thermal Systems Manager) - computer modelling of the sunshield was conducted with designs from 2 layers to 7 layers. The 5 layer design was chosen as the most effective trade off for creating a structure that supplied the required level of cooling and redundancy, while saving weight and complexity over the 6 and 7 layer options.

Sunshield Video Overview

In Depth

NASA and its industry partners developed a lightweight, robust way to protect the telescope and mirrors from the sun's infrared radiation in the material that makes up the sunshield. Key design attributes that make the sunshield unique are discussed below including its strong yet ultra-thin material, special kite-like shape, and the special role of its layers.

Sunshield Material

The sunshield is made of a lightweight material with special thermal properties, called Kapton, which is also specially coated.

The shiny silver material is a complex and innovative feat of material science and engineering. Each layer is made from a unique composite material, each has a specific thickness and size, and they must be precisely separated in space. There are even special seams and reinforcements to limit meteorite damage.

The sunshield consists of five layers, each layer is coated with aluminum, and the sun-facing side of the two hottest layers (designated Layer 1 and Layer 2) also have a "doped-silicon" (or treated silicon) coating to reflect the sun's heat back into space. The "doped silicon" gives layers 1 and 2 there distinct lavender/pink color.

The Sunshield's Kapton

Webb's sunshield made out of a thin material called Kapton. It shields the exposed mirrors and science instruments from the light and heat of the Sun, Earth and moon. How well can a material 1/1,000th of an inch thick work? Find out on this Episode of Elements of Webb.

Learn MoreKapton is a polyimide film that was developed by DuPont in the late 1960s. It has high heat-resistance and remains stable across a wide range of temperatures from minus 269 to plus 400 Celsius (minus 452 to plus 752 degrees Fahrenheit). It does not melt or burn at the highest of these temperatures. On Earth, Kapton polyimide film can be used in a variety of electrical and electronic insulation applications.

The sunshield layers are also coated with aluminum and doped-silicon for their optical properties and longevity in the space environment. Doping is a process where a small amount of another material is mixed in during the Silicon coating process so that the coating is electrically conductive. The coating needs to be electrically conductive so that the membranes can be electrically grounded to the rest of JWST and not build up a static electric charge across their surface. Silicon has a high emissivity, which means it emits the most heat and light and acts to block the sun's heat from reaching the infrared instruments that are located underneath it. The highly-reflective aluminum surfaces also bounce the remaining energy out of the gaps at the sunshield layer's edges.

Extreme Temperatures and the Sunshield

The material of the sunshield does shrink as it gets colder, and the hot layers expand. Cooper said, "The Kapton variety minimizes this compared to some other material choices. We have tested the material so we know how much it shrinks. We account for this in both our manufacturing and in our analysis predictions of the shape we will get in space. We have also tested a one-third-scale five-layer sunshield at temperature and vacuum to verify our predictions."

Shape And Layers

The kite-like shape and the number of layers of sunshield both play an important role on the telescope. Each of the different layers are positioned and separated with precision to accomplish their function.

"The shape and design also direct heat out the sides, around the perimeter, between the layers," said James Cooper, James Webb Space Telescope Sunshield Manager at NASA's Goddard Space Flight Center, Greenbelt, Maryland. "Heat generated by the Spacecraft bus at the “core,” or center, is forced out between the membrane layers so that it cannot heat up the optics."

"The five layers are needed to block and re-direct enough heat to get the telescope down to required temperatures, with margin," Cooper said. "The fifth layer is mostly for margin against imperfections, micro-meteoroids holes, etc." The gap between the layers provides an additional insulating effect.

Each layer of the sunshield is incredibly thin. Layer 1 faces the sun and is only 0.05 millimeters (0.002 inches) thick, while the other four layers are 0.025 mm (0.001 inches). The thickness of the aluminum and silicon coatings are even smaller. The silicon coating is ~50 nanometers (nm) (1.9 microinches) thick, while the aluminum coating is ~100 nm (3.93 microinches) thick.

The layers are slightly different sizes and different shapes. Layer 5 (just under the primary mirror) is smallest and Layer 1 is largest. Layer 1 is relatively flat and layer 5 is more curved. The layers are closer together at center and further apart at the edges to direct heat from center to the outside of the layers. In general, the layers are as close as an inch or two to each other at the center and around 10" apart from each other at the edges.

Thermal models show that the max temperature of Layer 1 is 383K. The max temperature of Layer 5 is 221K, and its minimum temperature is a chilly 36K.

The telescope optics (like the infrared camera and mirrors) must always be protected from direct exposure to any hot objects. So the membranes are sized and positioned such that the mirrors only have a direct line of sight to the cold Layer 5, while the sun only directly shines on Layer 1 no matter which way the observatory is pointed.

Special Seaming

The membrane material is tough, but if it gets a small tear or hole, the hole could become much larger. So, there is a special process called a Thermal Spot Bond (TSB) - areas where each layer are melted together. In addition, reinforcing strips of membrane material are Thermal Spot Bonded to the parent membrane about every 6 feet or so, forming a grid pattern of "rip-stops."

"This has been shown through testing to arrest a tear and keep it from extending outside of a given grid area," said Cooper. So, if a hole occurs in a layer of the sunshield from a meteoroid, or small meteor, the size of the damage is limited. These are not intended to stop a meteoroid, but rather to contain the area of damage.

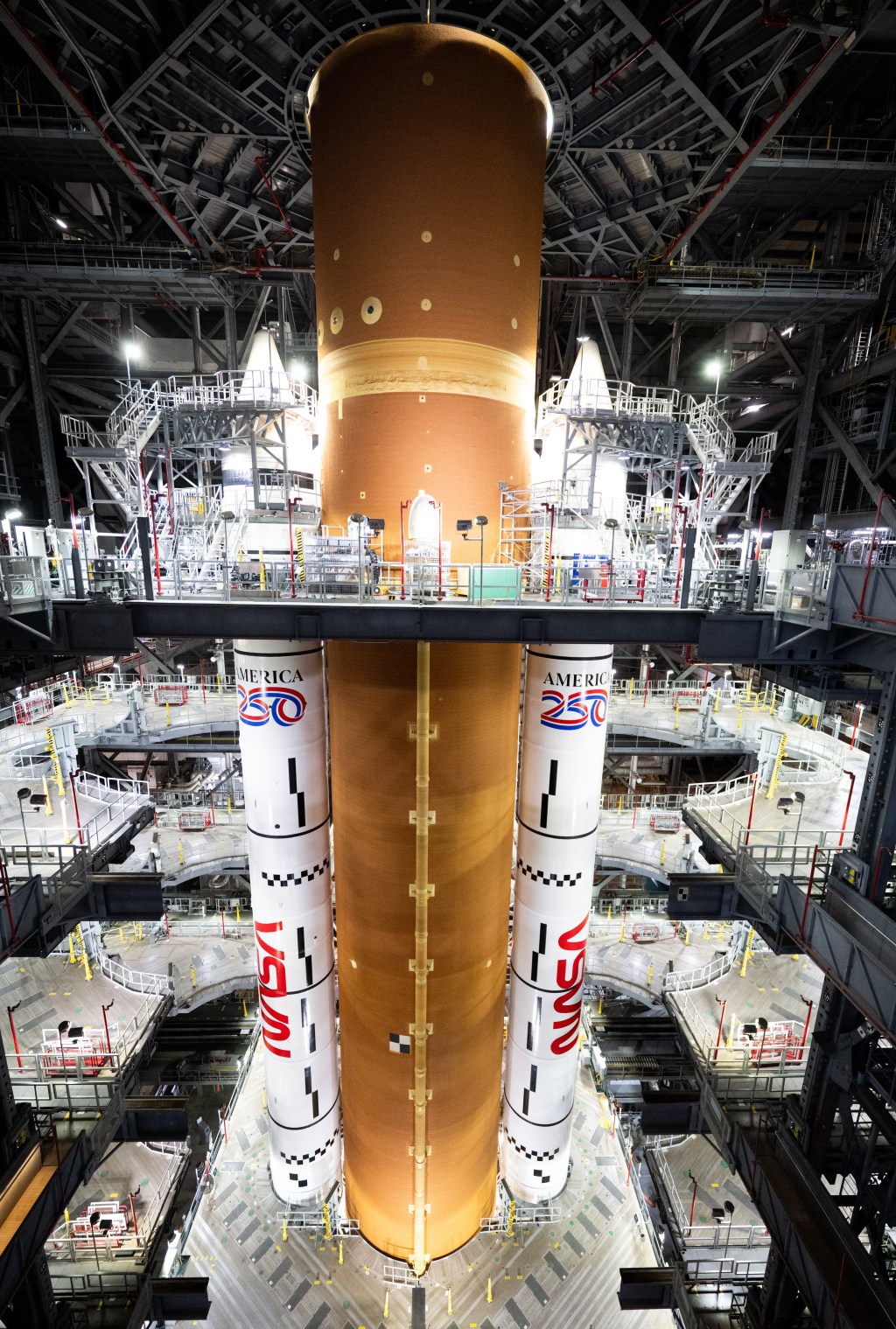

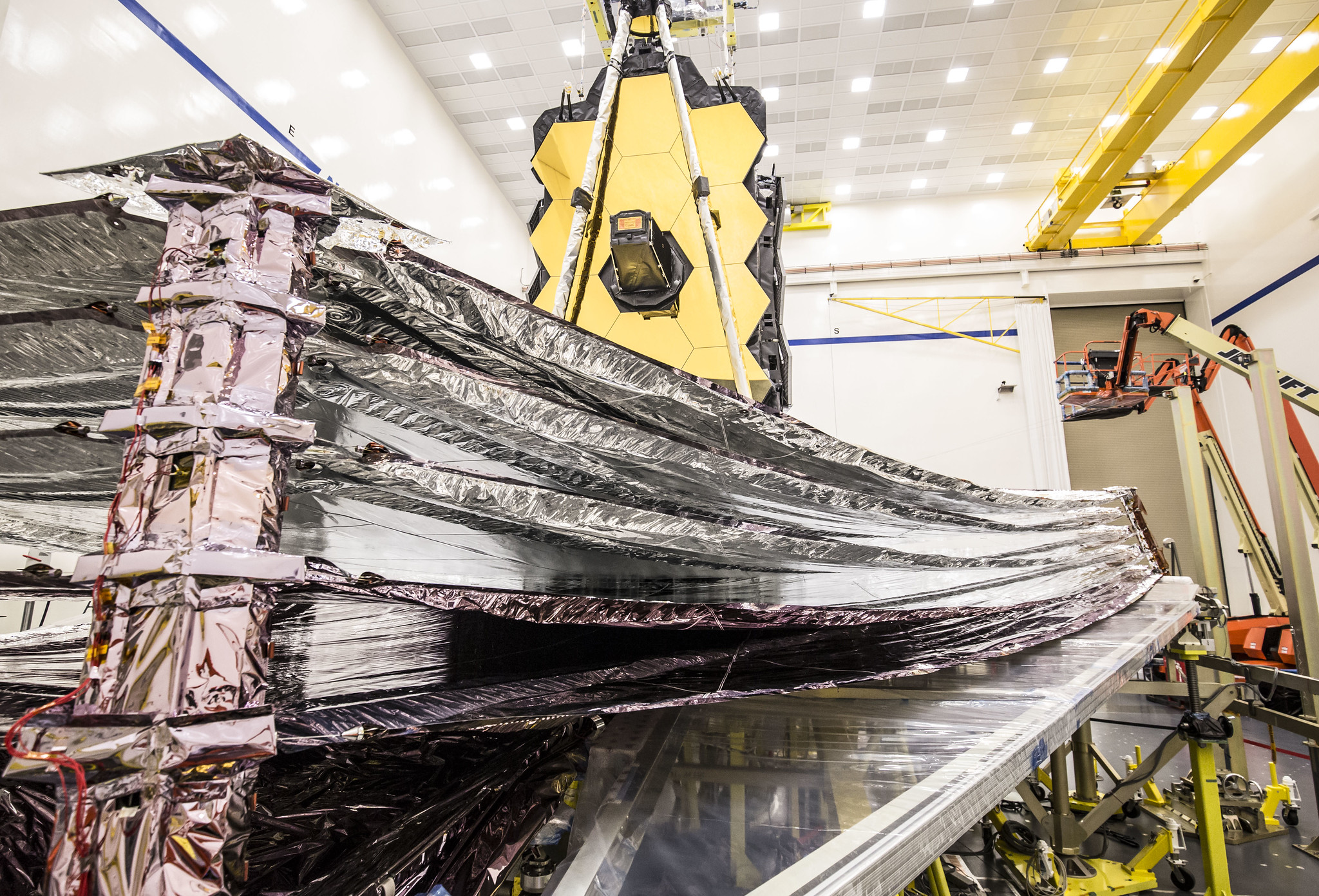

Folding for Launch

Since Webb is too large to fit inside a rocket in its “deployed,” or operational, form, Webb’s enormous sunshield was elaborately folded and secured to both fit in the rocket’s nose cone and be strong enough to survive the ride into space.

Preparing the sunshield for launch and deployment

How do you prepare a mission critical subsystem that is tennis court sized, 5 layers, each thinner than a human hair and precision aligned on deployment to fit in a rocket, endure launch and deploy perfectly in zero G? This article documents the final sunshield preparations for launch.

Read the Story

The sunshield was specially engineered to fold up around the two sides of the telescope and fit within the confines of its launch vehicle, the Ariane 5 rocket.

Fully deployed, the telescope’s sunshield measures almost 70 feet by 47 feet (21 meters by 14 meters). When stowed inside the rocket for launch, the folded sunshield was packaged in a very confined area in between other structures of the observatory to accommodate the limited space inside the 18-foot (5.4-meter) diameter rocket fairing.

The first layer of the sunshield is two-thousandths of an inch (0.005 centimeters) thick, while the other four layers are only one-thousandth of an inch thick. For the team, a built-in challenge was the delicacy of folding such thin layers. The folding process also had to account for components such as the sunshield’s 90 different tensioning cables, which must be stowed in a specific manner to ensure the sunshield deploys smoothly.

Webb needed its sunshield to be perfectly stowed to ensure that it openned up perfectly and maintained its shape, in order to successfully keep the telescope at its required operating temperature.

Sunshield Deployment

In the two weeks after launch, the entire observatory underwent a highly choreographed transformation—unfurling, extending and expanding to a configuration that is very different to how it looks when stored inside the rocket for liftoff. The sunshield unfolded at the end of the telescope’s first week in space after launch, stretching out to its full size and then separating and tensioning each of its five layers.

Webb's Sunshield Deployment

This video starts at the point it shows an animation of Webb's sunshield deploying. You can play the entire video to see Webb's full deployment sequence.

The sunshield support structure contains well over 7,000 flight parts, including springs, bearings, pulleys, magnets, etc. In addition, the sunshield has hundreds of custom fabricated pieces. Most mechanical pieces were developed exclusively for the sunshield, with a few from existing designs.

There are about 150 mechanism assemblies that have to function properly to fully deploy the sunshield. Within those mechanism assemblies, there are numerous small parts that work in harmony. The smaller parts include about 140 release actuators, approximately 70 hinge assemblies, eight deployment motors, scores of bearings, springs and gears, about 400 pulleys and 90 cables.

Video: Time-Lapse of Final Sunshield Test

These mechanisms release the sunshield membranes from their folded and stowed launch configuration, deploy the supporting structures, and unfold and tension the membrane layers. In addition there are hundreds of magnets and clips to manage the membrane shape and volume during deployment, and many sensors to tell engineers that each deployment step has been completed.

View Actual NASA Live Coverage of the Sunshield Deployment

Relive and learn from this live video coverage of Webb's sunshield deployment in space on its flight to L2 in January 2022. Beside reporting on the status of the deployment, engineers and scientists discuss many aspects of Webb's sunshield design and deployment.

Watch on YouTube (new tab)