Impacts and Benefits

The James Webb Telescope is having a unique and profound role in transforming our understanding of astrophysics and the origins of galaxies, stars, and planetary systems. In order to carry out its mission, several innovative and powerful new technologies ranging from optics to detectors to thermal control systems have been developed.

Innovation

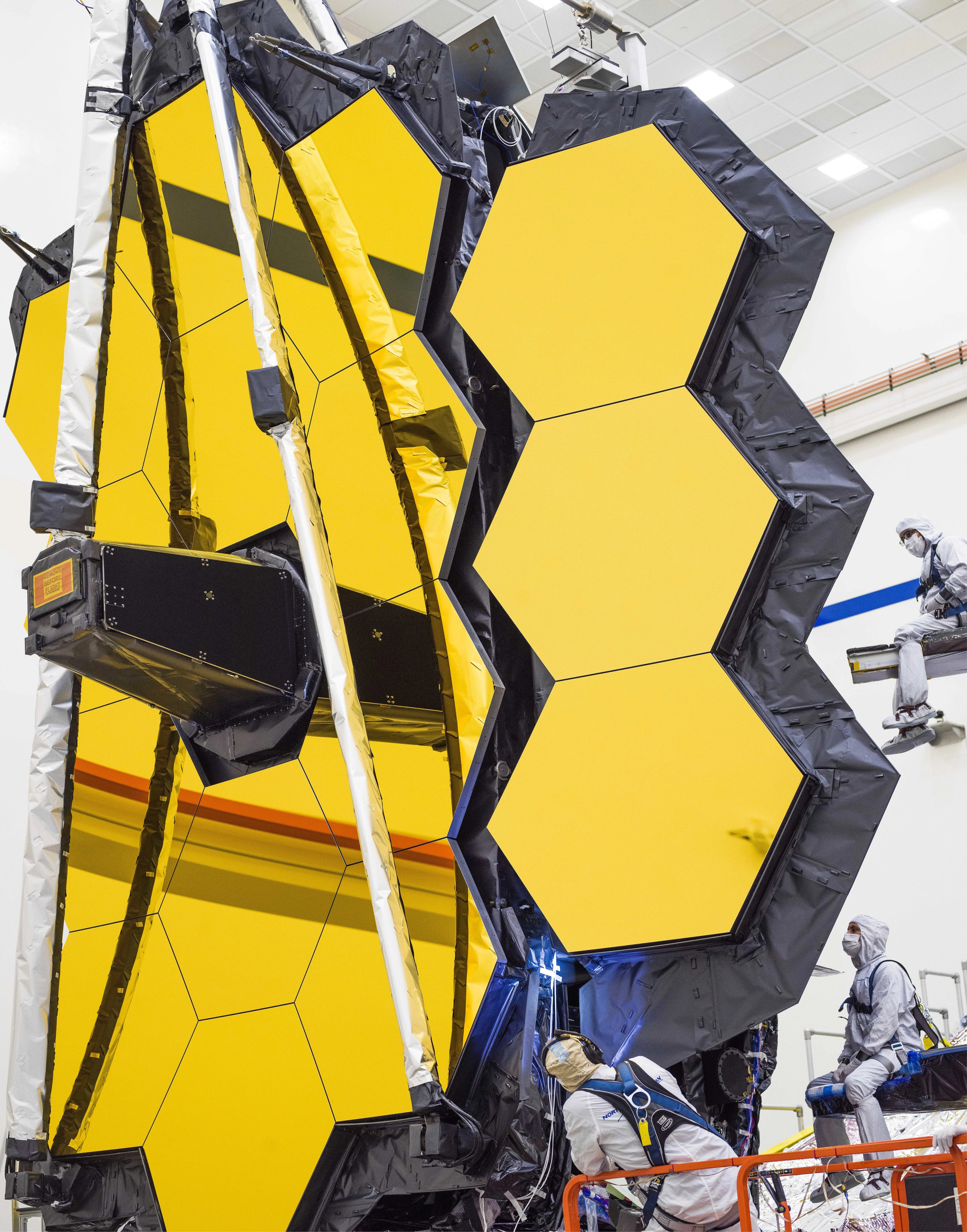

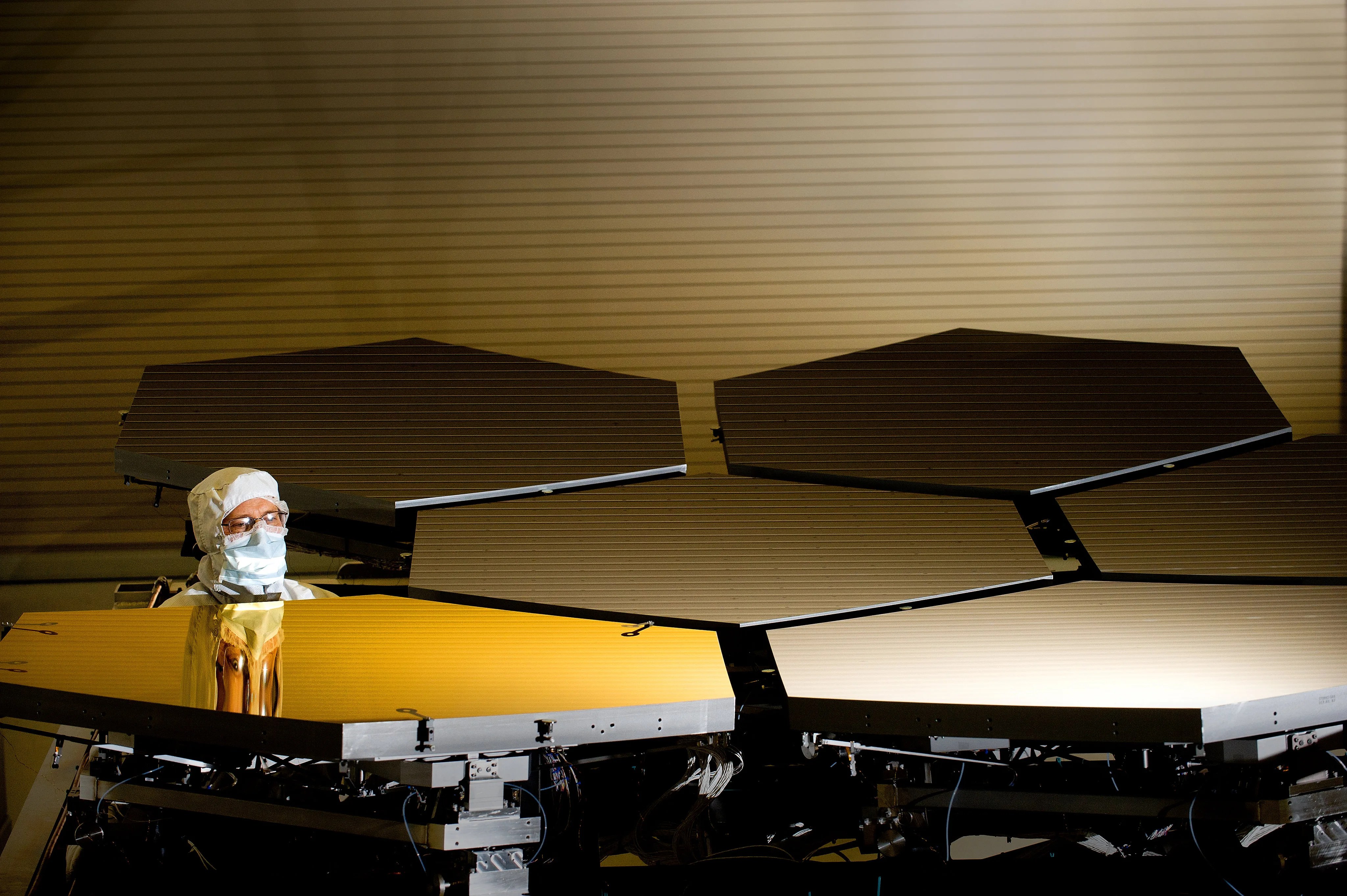

Folding Lightweight Adjustable Cryogenic Mirrors

Innovation

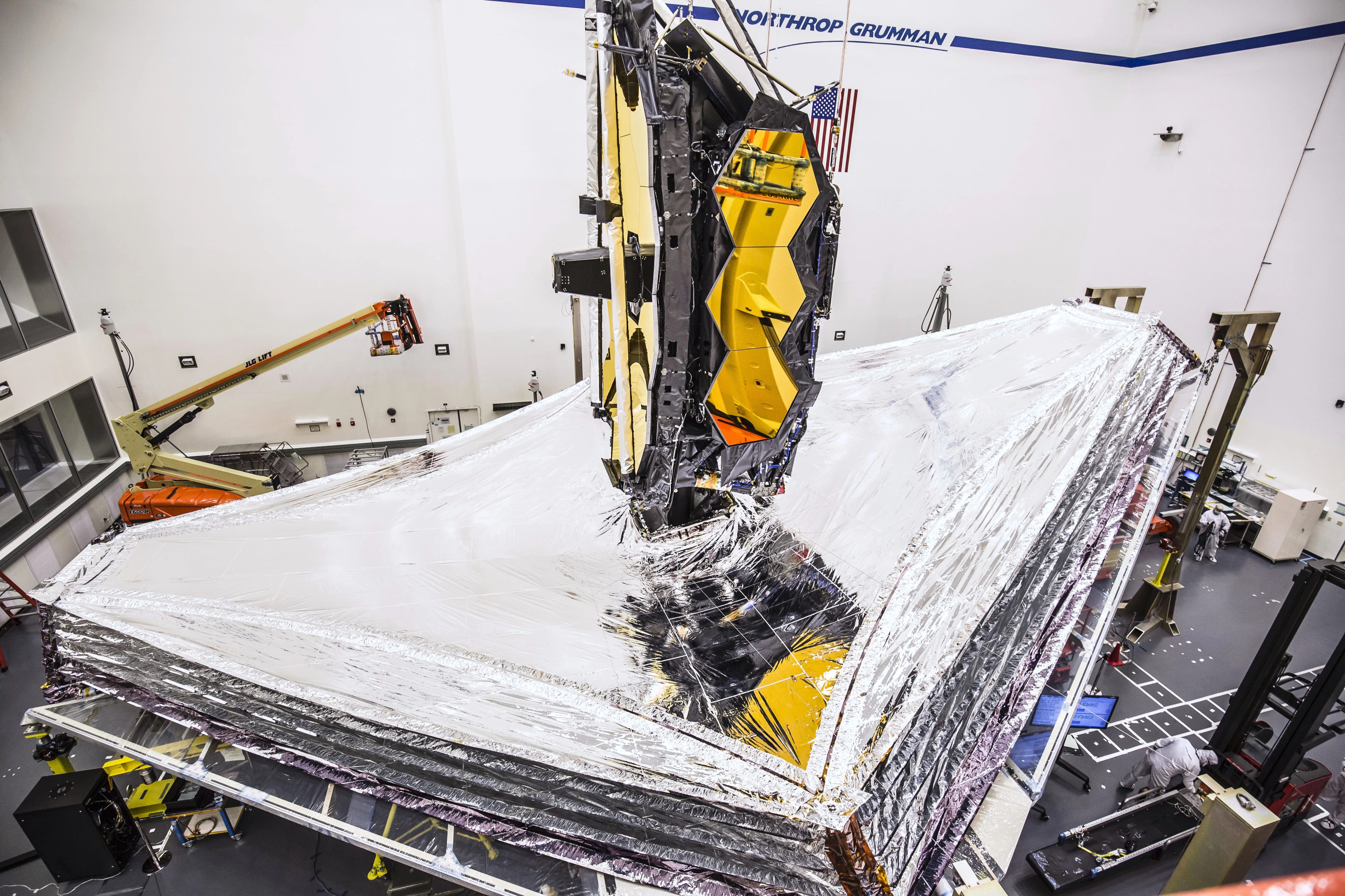

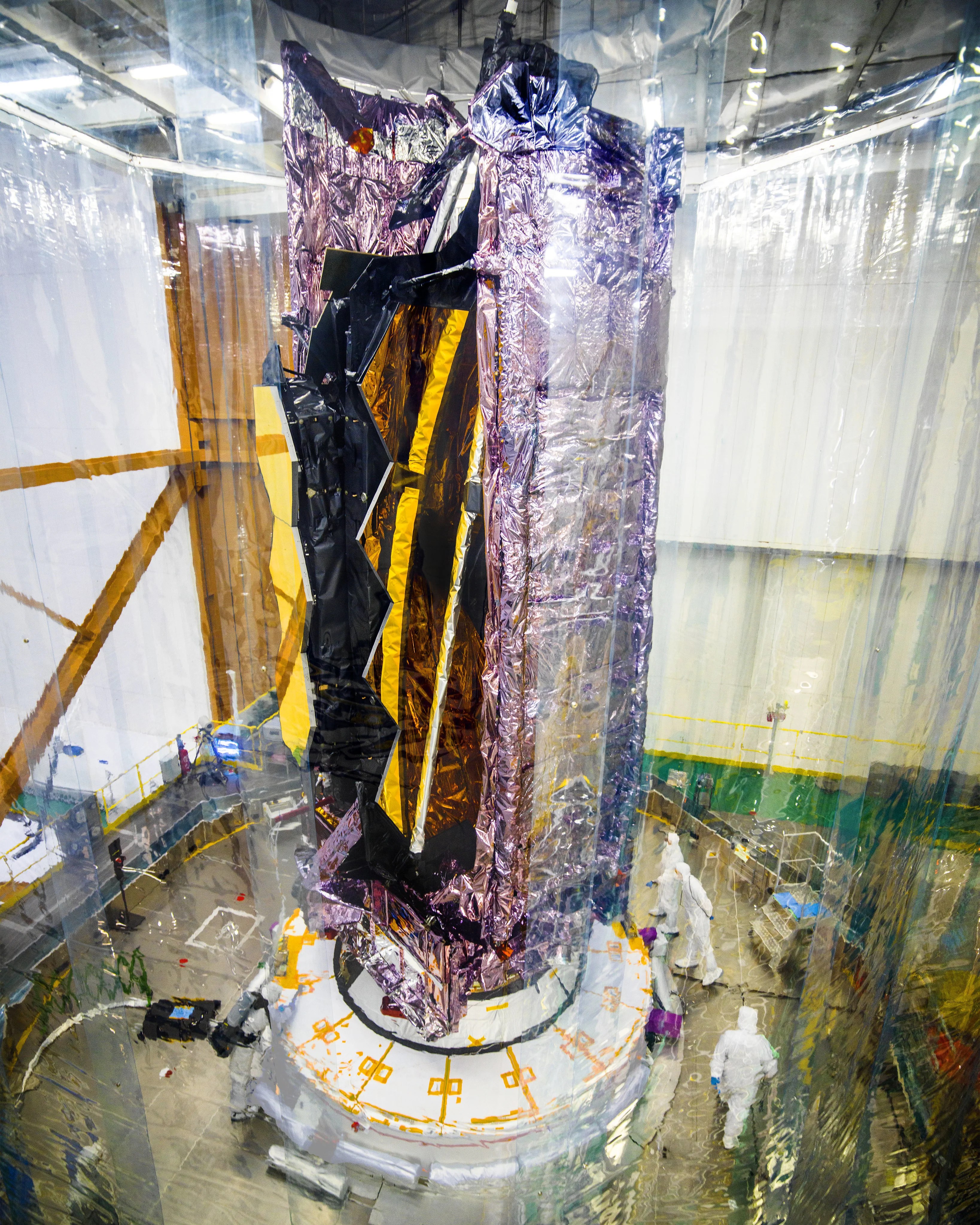

5 layer Sunshield : from ~185f (85C) to -388F (-233C) in 4.5 meters

Innovation

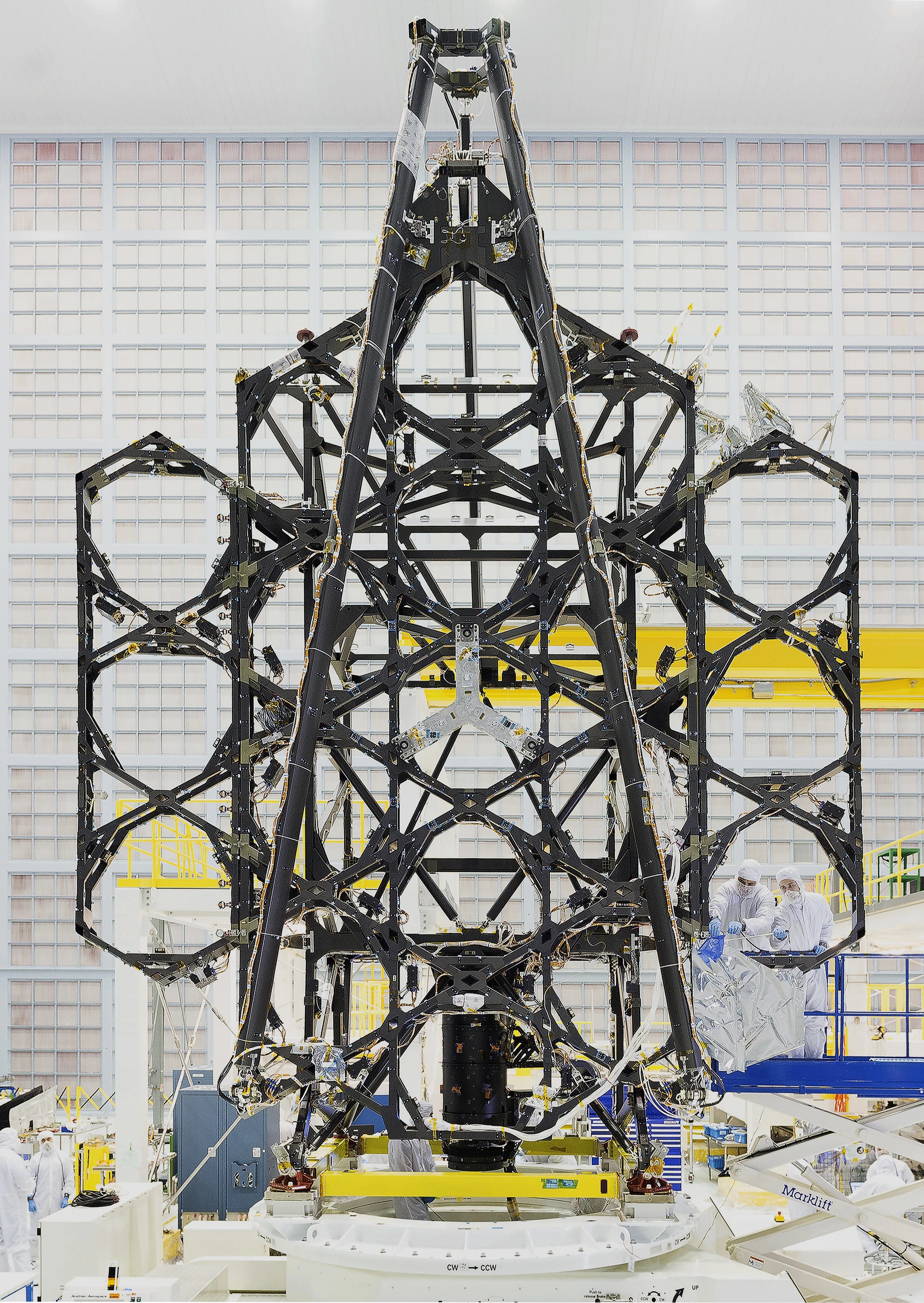

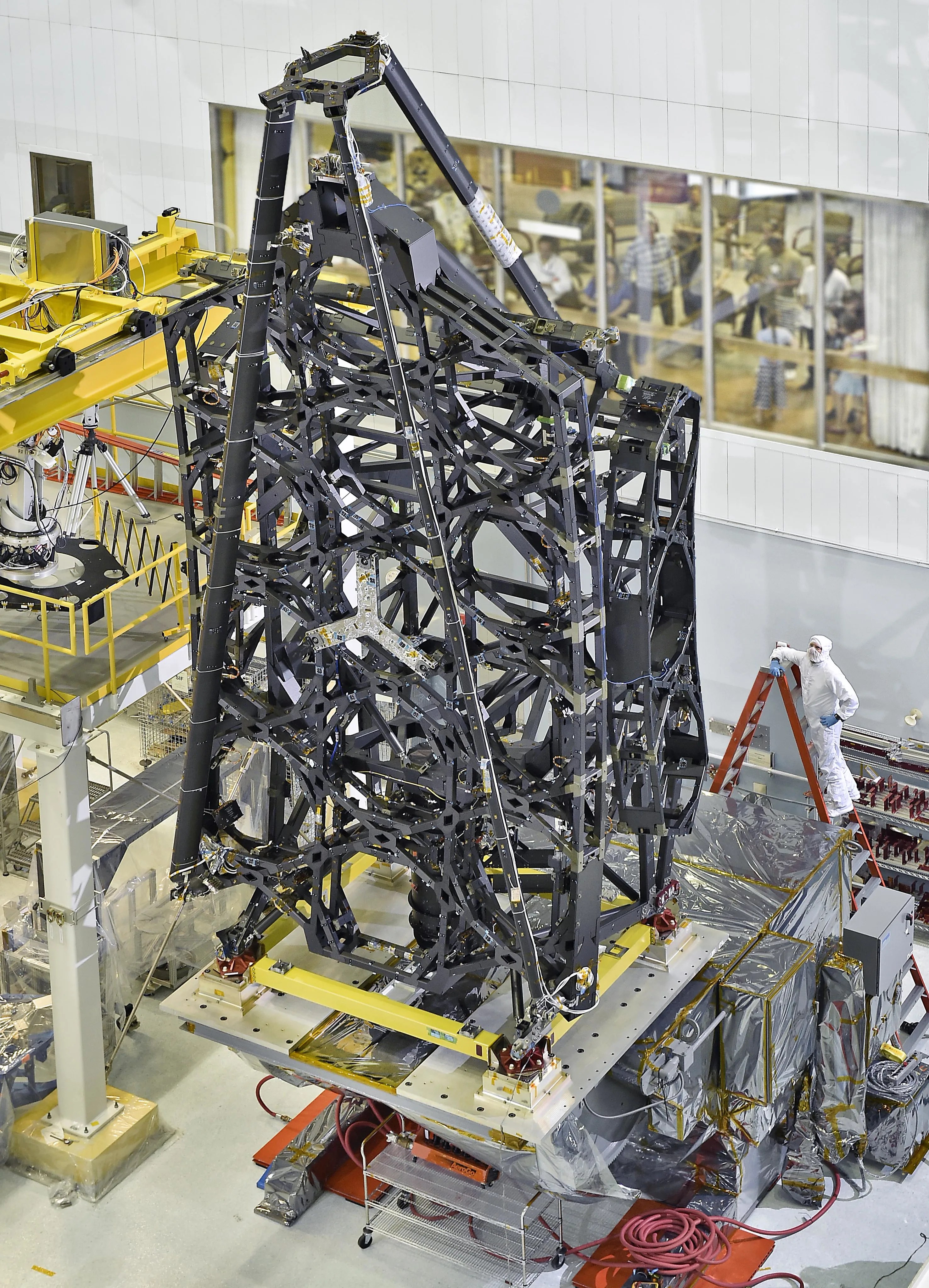

Backplane : carries 2.5 tons, steady down to 32 nanometers

Innovation

Cryocooler, Microshutters, Cryogenic ASICs

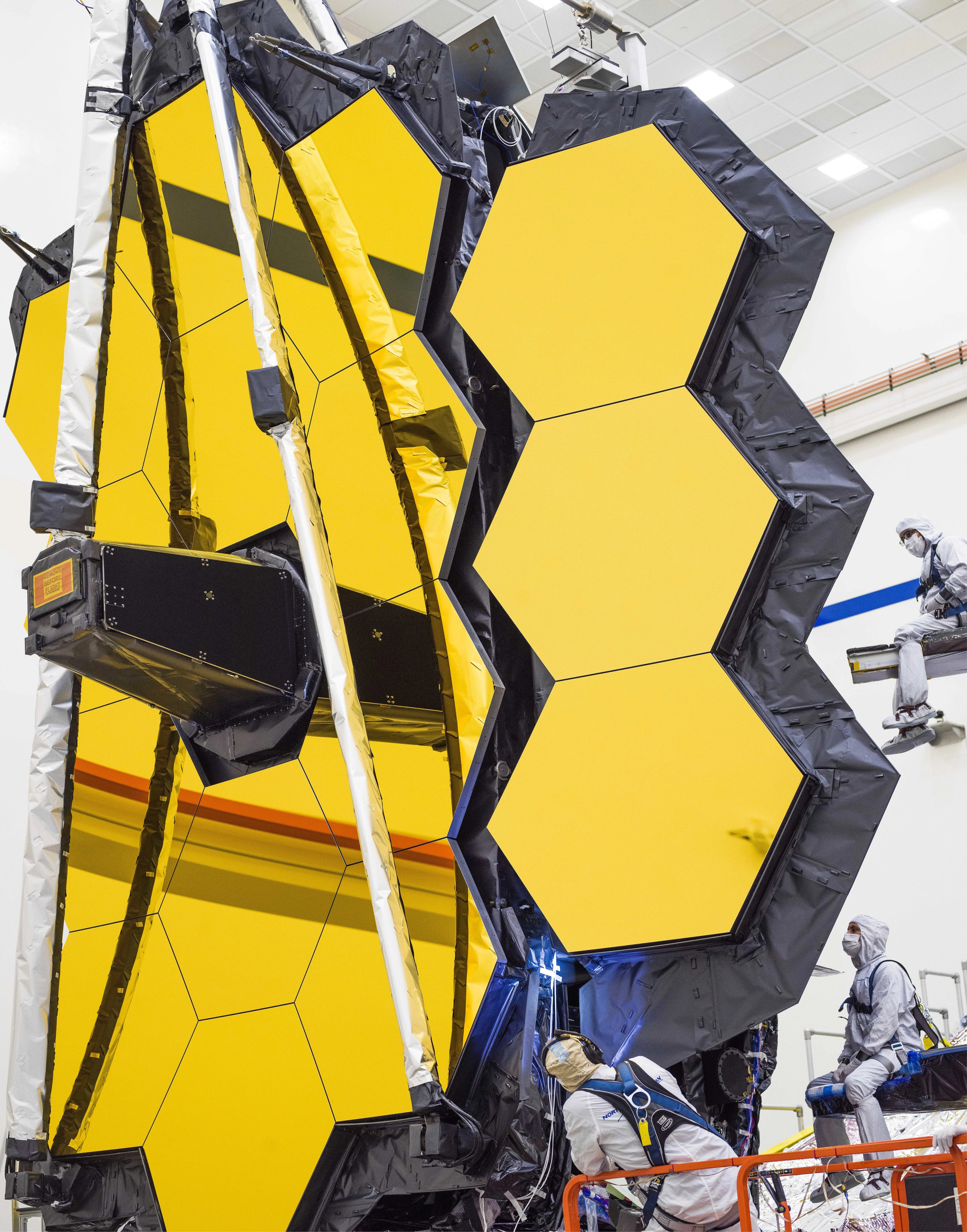

Innovations include a primary mirror made of 18 separate segments that unfold and adjust to shape after launch. The mirrors are made of ultra-lightweight beryllium. Webb’s biggest feature is a tennis court sized five-layer sunshield that attenuates heat from the Sun more than a million times. The telescope’s four instruments – cameras and spectrometers – have detectors that are able to record extremely faint signals. One instrument (NIRSpec) has programmable microshutters, which enable observation up to 100 objects simultaneously. Webb also has a cryocooler for cooling the mid-infrared detectors of another instrument (MIRI) to a very cold 7 K to operate properly.

- MIRRORS - Folding segmented mirror : The Webb Telescope team decided to build the mirror in segments on a structure which folds up, like the leaves of a drop-leaf table, so that it can fit into a rocket.

- MIRRORS - Lightweight optics : NASA set out to research new ways to build mirrors for telescopes. The Advanced Mirror System Demonstrator (AMSD) program was a four-year partnership between NASA, the National Reconnaissance Office and the US Air Force to study ways to build lightweight mirrors.

- MIRRORS - Cryogenic actuators & mirror control : Lee Feinberg, Webb Optical Telescope Element Manager at NASA Goddard explains, "Aligning the primary mirror segments as though they are a single large mirror means each mirror is aligned to 1/10,000th the thickness of a human hair. What's even more amazing is that the engineers and scientists working on the Webb telescope literally had to invent how to do this."

- MIRRORS - Wave Front Sensing: Wavefront sensing and control was developed to sense and correct any errors in the telescope's optics. This is essential to making the 18 mirror segments work together as a single giant mirror.

- Webb's Sunshield : The sunshield reduces the temperature between the hot and cold side of the spacecraft by almost 600 degrees Fahrenheit in the span of its 5 layer, 4.8m height - from approximately 185F (85C) on the hot side to approximately -388F (-233C) on the cold side.

- Sunshield coatings: Webb deployed a tennis-court sized Sunshield made of five thin layers of Kapton E with aluminum and doped-silicon coatings to reflect the sun's heat back into space.

- Improved Detectors: Webb has extended the state of the art for infrared detectors by producing arrays that are lower noise, larger format, and longer lasting than their predecessors.

- Micro-shutters : Microshutters are tiny windows with shutters that each measure 100 by 200 microns, or about the size of a bundle of only a few human hairs. The microshutter device can select many objects in one viewing for simultaneous high-resolution observation which means much more scientific investigation can get done in less time.

- Cryocooler: Webb's MIRI instrument carries detectors that need to be at a temperature of less than 7 kelvin to operate properly. This temperature is not possible on Webb by passive means alone, so Webb carries an innovative "cryocooler" that is dedicated to cooling MIRI's detectors

- Backplane : The backplane must carry more than 2400kg (2 1/2 tons) of hardware. It is required to be essentially motionless so the mirrors can see far into deep space. To meet this requirement, the backplane was engineered to be steady down to 32 nanometers, which is 1/10,000 the diameter of a human hair.

- Cryogenic Data Acquisition ASIC : "A-to-D" conversion is nothing new, but the technical challenge that Webb faced was doing it at the observatory's super-cold cryogenic operating temperatures in an Application-Specific Integrated Circuit (ASIC).

Related Images