PROJECT

Microgreens Root Zone/Shoot Zone Separator Planting Box project

SNAPSHOT

Harvesting and containment technologies for microgreens may allow astronauts to add these delicious, nutritious crops to their space diet.

Astronauts on long-duration exploration missions may consume fresh produce to add bioavailable nutrients and variety to their packaged diet. Microgreens are nutritious and delicious, but growing and harvesting these small, densely packed plants without gravity could be challenging. NASA has recently developed some candidate approaches to these challenges and has tested them using parabolic flights to provide short durations of microgravity.

Kennedy Space Center is home to NASA’s space crop production research efforts, including a team focused on growing crops to feed astronauts during future space exploration missions. While the current space diet is excellent, with numerous highly palatable foods, both the nutritional content and the food quality can degrade if those foods are stored for long durations.

Microgreens are small, densely grown, young plants that have great potential as space crops. The term “microgreens” actually describes the growth stage of the plant, where true leaves are just emerging. Because microgreen plants are harvested when they are small, many seeds are planted in a dense configuration to provide sufficient salad to eat. Microgreens require few resources to grow, needing little to no fertilizer and relatively low light. While many seeds are required, the seeds are generally small and lightweight, so a large number can be packed into a tiny cargo. Microgreens grow fast, with most being ready to harvest between 7 and 14 days.

Nearly any plant whose leaves, stems, or even roots are edible can be grown and eaten as a microgreen. Some common types of crops grown as microgreens include broccoli, radish, carrot, basil, and even sunflower. Microgreens are nutrient-dense; the nutritional composition of a microgreen is between 4 and 10 times that of the same plant grown to maturity. And microgreens are delicious, with flavors concentrated in these tiny plants.

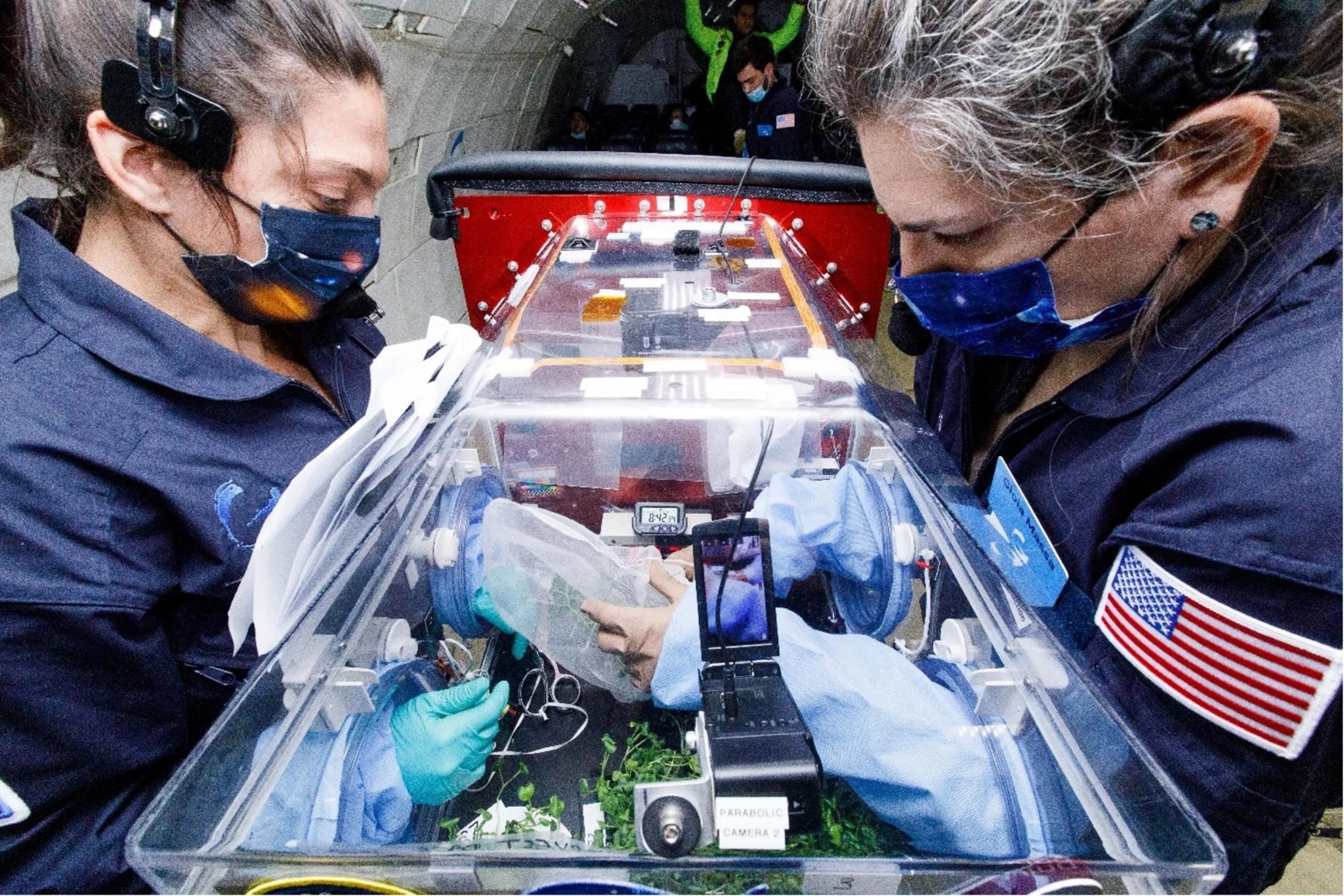

However, growing and harvesting microgreens in space without gravity is challenging. Plant roots grow in contact with water and fertilizer, and thus tend to have much higher levels of microbial contamination, which can present food safety concerns. Therefore, only the microgreen shoots are consumed in space. In addition, harvesting microgreens requires cutting the small plant stems and then collecting the cut plants. On Earth microgreens are cut with scissors and bagged by hand, though commercial operations may use automatic or robotic harvesting methods. In space, once the stems are cut, these tiny plants may float around the spacecraft as debris and become difficult to collect and capture. To address these issues, the Kennedy team developed several concepts for growing microgreens with separate root and shoot zones and harvesting and containing them in microgravity.

The Kennedy team designed growth boxes that separate the root zone and the shoot of the microgreens. Separating the root and shoot zone not only allows us to understand and characterize the growing shoots by measuring photosynthesis and water loss from the canopy, it also allows for a way to harvest the plant and limit contamination from the roots.

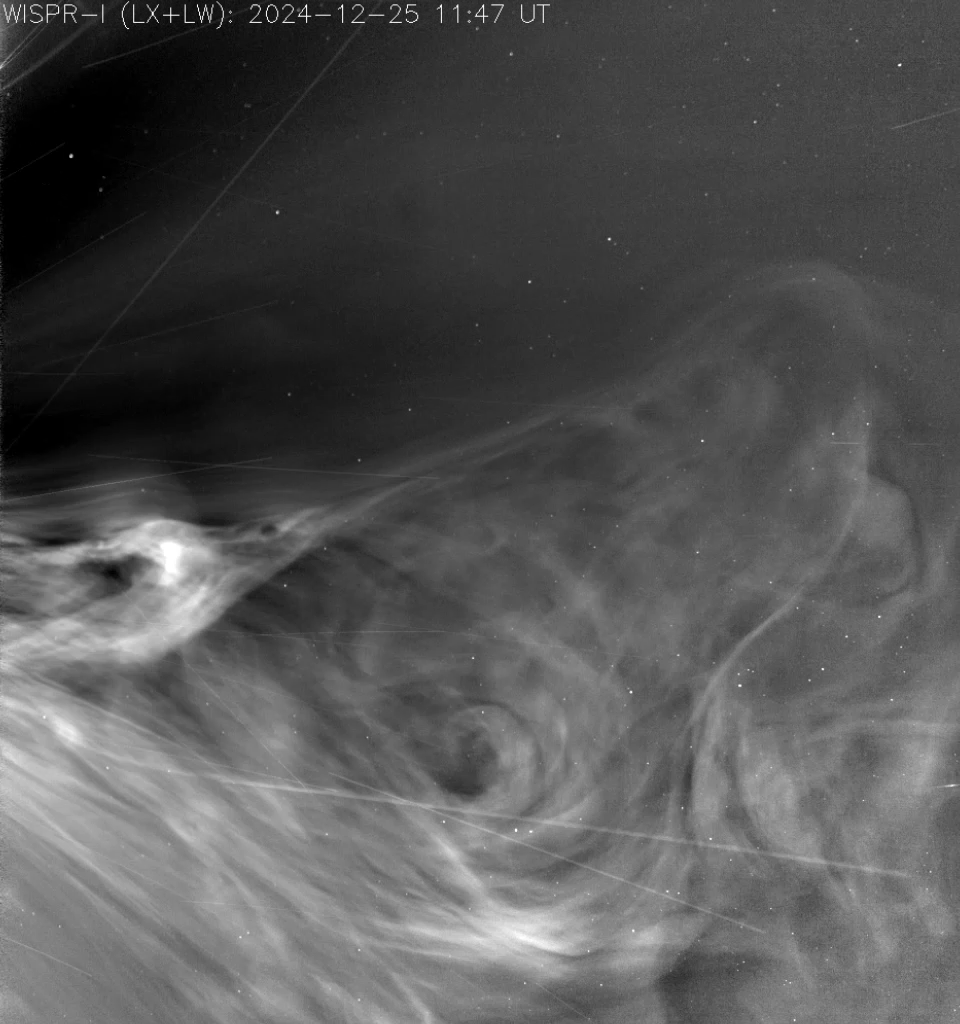

The Kennedy team tested these growth boxes with different harvesting and bagging methods on parabolic flights. On a parabolic flight, the airplane’s trajectory consists of a series of parabolas, each of which provides approximately 20 seconds of weightlessness followed by 20 seconds of high gravity. Research flights typically follow a trajectory consisting of a series of six groups of five parabolas. In the Kennedy team’s microgreen test flights, the first group of parabolas induced Martian (3/8 g) and Lunar (1/6 g) gravity levels instead of weightlessness.

Three different harvesting methods were tested in parabolic flight including the traditional approach of using scissors, another using a sliding blade we called “the guillotine,” and a third we called a “pepper grinder,” which consists of two plates that when counter-rotated sever the microgreen. Bagging or containment approaches tested included both manual bagging into a zip-top bag, and using a removable mesh bag with a drawstring that was attached to the growth boxes. Both bagging methods were tested with all three harvesting approaches.

Because these plants are small and would float away and potentially be lost in a parabolic flight aircraft, our team conducted the harvests inside a glove box to contain any free-floating plants and debris during the harvests. The glovebox also included cameras to record the activities inside the box, as well as an accelerometer to record the gravity levels and a timer to keep track of the duration of operations. This glovebox has been used in multiple parabolic flights and was provided by Dr. George Pantalos, University of Louisville, who also served as ground support for our flights. Three team members on each flight took turns either operating the harvest procedures, assisting with the harvest operations, or coaching on timing, gravity stages, and next steps.

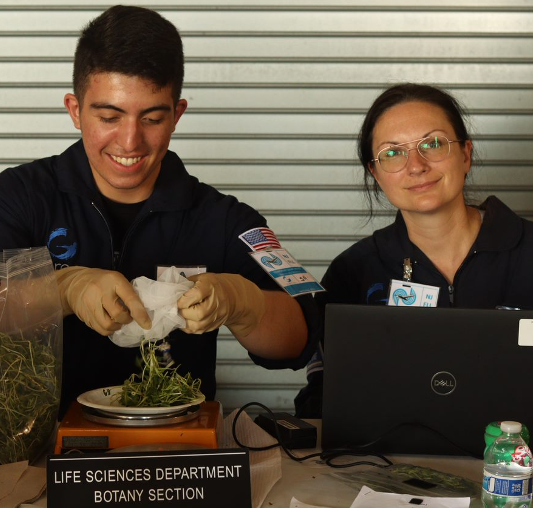

The team participated in three parabolic flights and conducted 24 different harvests during each parabolic flight. Data were collected via video as well as questionnaires that the operators filled out. In between each set of parabolas, the harvested boxes and bagged microgreens were removed from the glovebox, any debris was cleaned up, and fresh boxes and harvest bags were installed in the glovebox. After each flight, the harvested microgreens were weighed, and photos of the harvested boxes were taken to see how cleanly plants were cut and what plants and debris remained. The number of loose microgreens generated during each harvest and the effectiveness of the various harvest approaches are being assessed from the videos and data virtually by intern Haley Boles.

In addition, students involved in the citizen science education program Growing Beyond Earth, run by Fairchild Tropical Botanic Garden in partnership with NASA, have helped our team test other box configurations and plant species as part of this project. Christopher Bermudez, a student intern at Fairchild Garden, served on the ground team and was ground team photographer for the December parabolic flight tests.

It takes a village to feed a village, and space crop production research also involves a variety of different groups within NASA. This research project was supported by grants from NASA KSC’s Independent Research and Technology Development Program, NASA’s Flight Opportunities Program in the Space Technology Mission Directorate, NASA Postdoctoral Program Fellowships to Dr. Lucie Poulet and Dr. Christina Johnson supported by NASA’s Space Biology program in the Biological and Physical Sciences Division. The Growing Beyond Earth Program is supported by a grant from NASA’s Office of Science, Technology, Engineering, and Math (STEM) Engagement.

PROJECT LEADS

Dr. Gioia D. Massa, Dr. Lucie Poulet. and Dr. Christina Johnson, NASA Kennedy Space Center (KSC)

SPONSORING ORGANIZATIONS

NASA KSC’s Independent Research and Technology Development Program, NASA’s Flight Opportunities Program (STMD), NASA Biological and Physical Sciences Program.

Read more Technology Highlights