PROJECT

MAGnetometers for Innovation and Capability (MAGIC)

SNAPSHOT

A NASA-sponsored team at the University of Iowa is rediscovering and improving lost techniques to develop high-fidelity instruments needed to make the magnetic field measurements that enable many of the nation’s space science and space weather missions.

Fluxgate magnetometers are essential and widely-used space science and space weather instruments, but they depend on a legacy component—a ferromagnetic core—that was developed and manufactured for the U.S. Navy using technology that has been subsequently lost to the civilian community. The stockpiles of these legacy cores are so depleted that some providers are now exploring destroying old flight-spare hardware to recover and refurbish the cores for use in new missions. This approach is obviously unsustainable. A NASA-sponsored research team at the University of Iowa is resurrecting fluxgate technology to enable a new generation of magnetic field instruments for future scientific and operational missions.

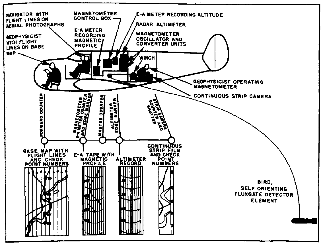

Fluxgate magnetometers have flown on a high percentage of space science missions and space weather missions to provide high-fidelity measurements of the local magnetic field. The instrument’s performance is limited by the magnetic noise of a specialized ferromagnetic core. The technology needed to create these cores was principally developed in the 1960s for military sensing applications such as submarine detection. Most spaceflight instruments are currently being built using a dwindling store of legacy cores, which were manufactured up to 1996 using unknown processes by companies and groups that no longer exist. Without a new source of high-quality space-qualified cores, the United States risks losing its capability to produce the world-class spaceflight fluxgate magnetometers that are used routinely by NASA, the National Oceanic and Atmospheric Administration, and the nation’s defense agencies.

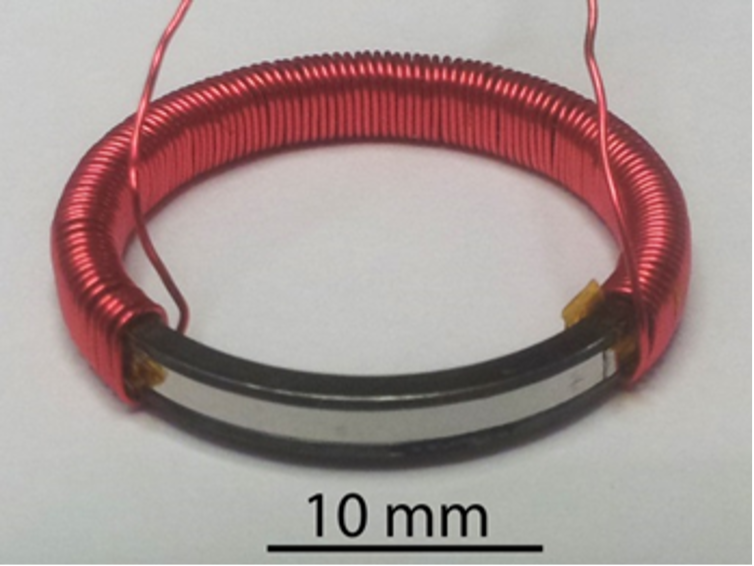

Fluxgate magnetometers deliver magnetic field measurements by periodically saturating a piece of ferromagnetic core material to modulate the local magnetic field and sensing this modulated magnetic field using a coil of wire. Fluxgate performance is limited by the intrinsic magnetic noise of the core as it enters magnetic saturation. The preferred ferromagnetic material used by manufacturers in North America and Western Europe was 6% Molybdenum, 81.3% Nickel, and remainder Iron (6-81 Permalloy). Incredibly, it appears that essentially all North American and European spaceflight Permalloy fluxgates were manufactured from a single melt of 6-81 Permalloy by the Hamilton Watch Company in around 1969 that was then rolled into 12-micron foil. That foil was then processed to engineer low magnetic noise cores by two groups – the U.S. Naval Surface Weapons Center (NSWC) White Oak (now a Department of Agriculture facility) and Infinetics Inc. Many of the best fluxgates worldwide have nearly identical sensors since they all appear to be using legacy Infinetics S1000 cores that have been out of production since 1996, for which information about the manufacturing process has been lost.

Development of future high-performance next-generation sensors requires the ability to produce new high-quality cores. A team at the University of Iowa, working with national and international collaborators, has demonstrated a manufacturing process that produces cores that match the noise performance of most cores in use today and has revealed potential optimizations that could enable lower noise sensors, miniature sensors for nanosatellites, and efficient high-volume production of sensors for constellation missions.

The University of Iowa team does not rely on legacy processes or materials. Rather, the new fluxgate cores are manufactured from scratch and integrated into a modern spaceflight magnetometer design. The ferromagnetic cores are produced starting from base metal powders that are melted into custom alloys in-house, cold-rolled into thin foils, formed into the geometry of a fluxgate core, and subjected multi-step heat treatments to optimize their magnetic properties. The team then integrates the resulting cores into a complete fluxgate sensor ready for a spaceflight application. Making fluxgate cores from scratch has enabled us to explore new designs such as the prototype ‘Tesseract’ high-stability sensor.

This work at the University of Iowa was started under a technology development grant sponsored by the Heliophysics Division’s Heliophysics Technology and Instrument Development for Science (H-TIDeS) program, and is continuing via the MAGnetometers for Innovation and Capability (MAGIC) Project sponsored by the NASA Explorers Program Office at Goddard Space Flight Center. MAGIC is a five-year effort to design, build, test, and fly a next-generation spaceflight fluxgate demonstrating the new core technology. In the last 18 months, MAGIC has established a new spaceflight instrument team and is undertaking two major technical projects. First, we are completing a detailed investigation into the factors that control magnetic noise in permalloy fluxgate sensors with the goal of achieving unprecedentedly low magnetic noise measurements and developing miniature sensors that match the noise performance of the larger cores in use today. Secondly, we are developing a complete flight-ready magnetometer design based on this new core technology. We will prove flight-heritage of this new technology through a do-no-harm technical demonstration as a hosted-payload on the Tandem Reconnection and Cusp Electrodynamics Reconnaissance Satellites (TRACERS) Small Explorer mission.

The ongoing availability of high-quality magnetic field instruments is essential to investigations that will enable NASA to meet the overarching Heliophysics goal to “Advance our understanding of the connections between the Sun, Earth, the planetary space environments, and the outer reaches of our solar system” and the 2019 National Space Weather Strategy and Action Plan Objective 2.4 to “Identify, develop, and test innovative approaches to enable enhanced, more informative, robust, and cost-effective measurements. … This action should include … the development of novel observational approaches …”. MAGIC is aligned with the 2020 NASA Technology Taxonomy and will help deliver the Analog Fluxgate Magnetometer (AFT) listed under Taxonomy Subarea TX08.3.1. Future missions of 10s to 100s of small, low-cost spacecraft each carrying a miniature magnetometer will enable us to characterize the global morphology of the magnetosphere.

PROJECT LEAD

Dr. David Miles, University of Iowa, Department of Physics and Astronomy

SPONSORING ORGANIZATION

The Heliophysics Division’s H-TIDeS Program sponsored initial work on this technology; the ongoing MAGIC technology demonstration is sponsored by the NASA Explorers Program Office at Goddard Space Flight Center