/Earth%20(B).tif?w=4095&h=4095&fit=clip&crop=faces%2Cfocalpoint)

How NASA’s Astrophysics Missions Power Life on Earth

NASA’s Astrophysics missions don’t just explore the cosmos—they generate technologies that transform our everyday lives.

How NASA’s Astrophysics Missions Power Life on Earth

What is Tech Transfer?

NASA’s Astrophysics missions don’t just explore the cosmos—they generate technologies that transform our everyday lives. From medical imaging to AI, the innovations developed for telescopes and observatories are powering change across industries. Here’s a look at some of the spinoffs born from NASA’s quest to understand the universe.

What is a Spinoff?

"Spinoffs" are NASA technologies that benefit life on Earth in the form of commercial products. NASA has profiled more than 2,000 spinoffs since 1976 — there’s more space in your life than you think!

Compact Spectrometer Technology

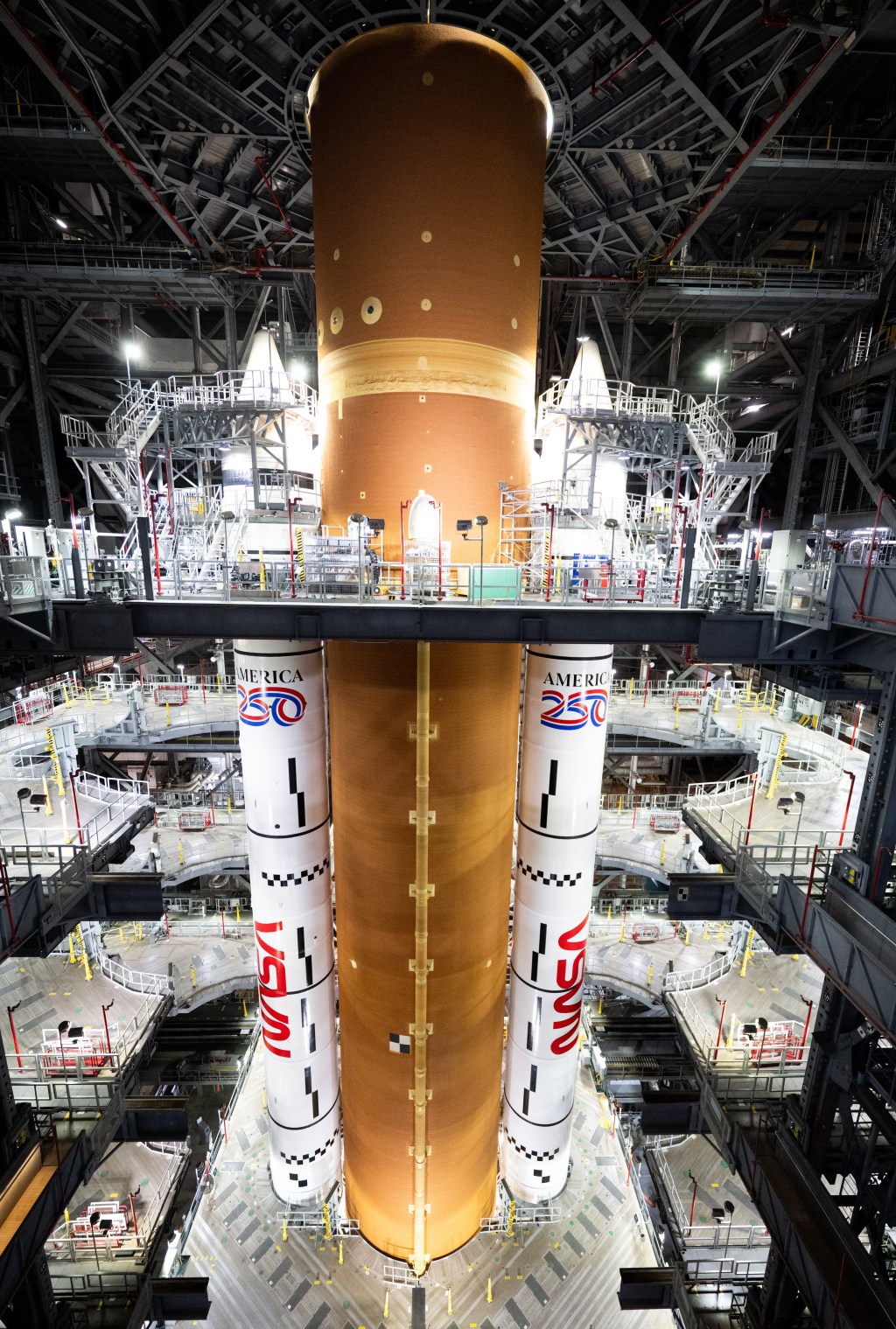

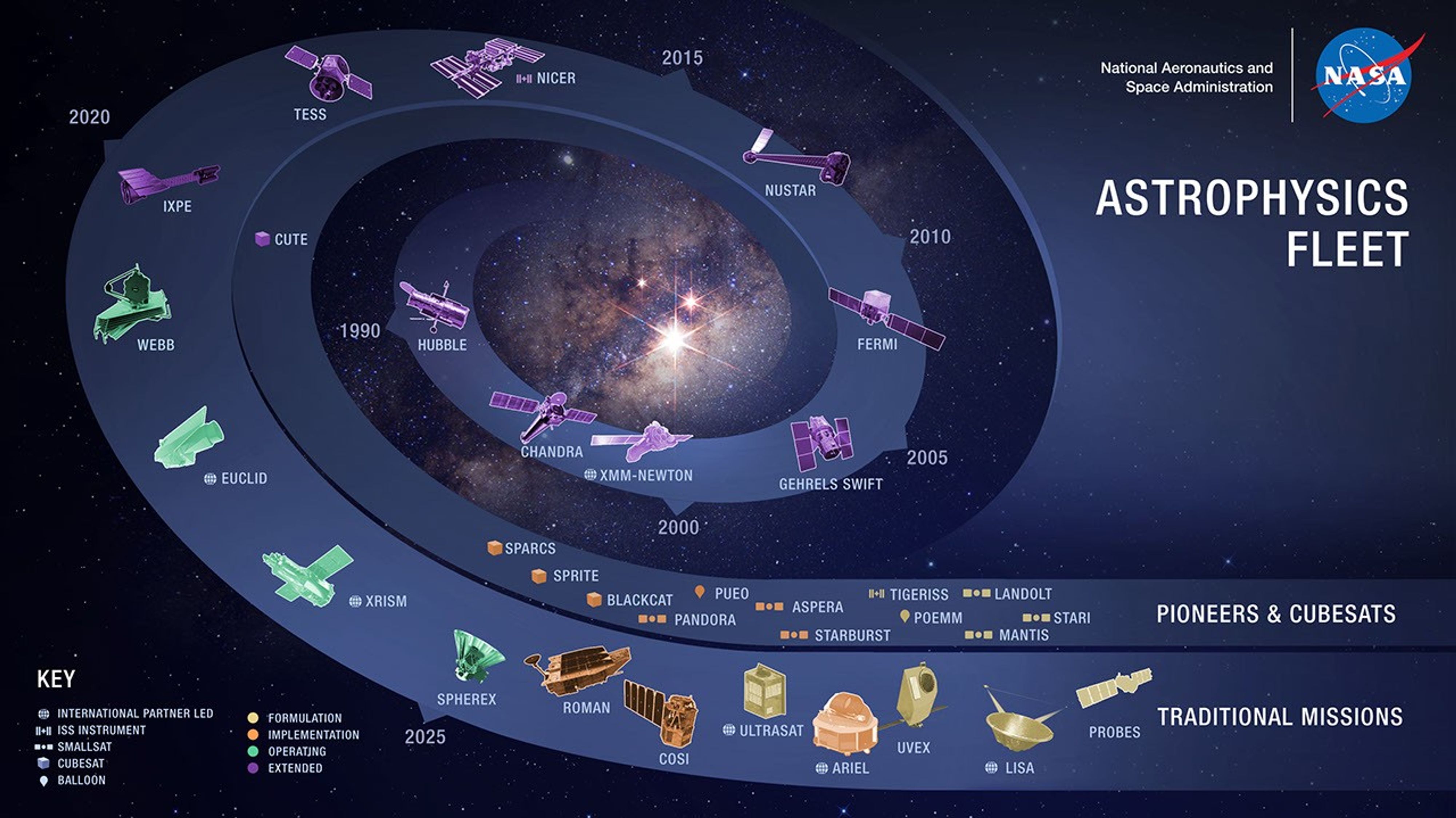

NASA Astrophysics Missions

NASA’s compact spectrometer advancements now aid in medical diagnostics and environmental monitoring. Initially developed to detect exoplanets, NASA-funded innovations led to the creation of high-resolution, compact spectrometers. Hindsight Imaging Inc. has adapted this technology for Earth-based applications, including non-invasive skin cancer detection, drug and explosive identification, and precision agriculture. These devices offer high performance in a smaller, more affordable package, expanding access to advanced diagnostic tools.

Learn More

Nickel-Hydrogen Battery Technology

Hubble Space Telescope

NASA’s durable space battery technology now powers renewable energy storage on Earth. Originally developed to power NASA’s Hubble Space Telescope, nickel-hydrogen batteries are renowned for their longevity and reliability. EnerVenue, a company based in Fremont, California, has adapted this technology for terrestrial use, providing safe and long-lasting energy storage solutions for renewable sources like solar and wind.

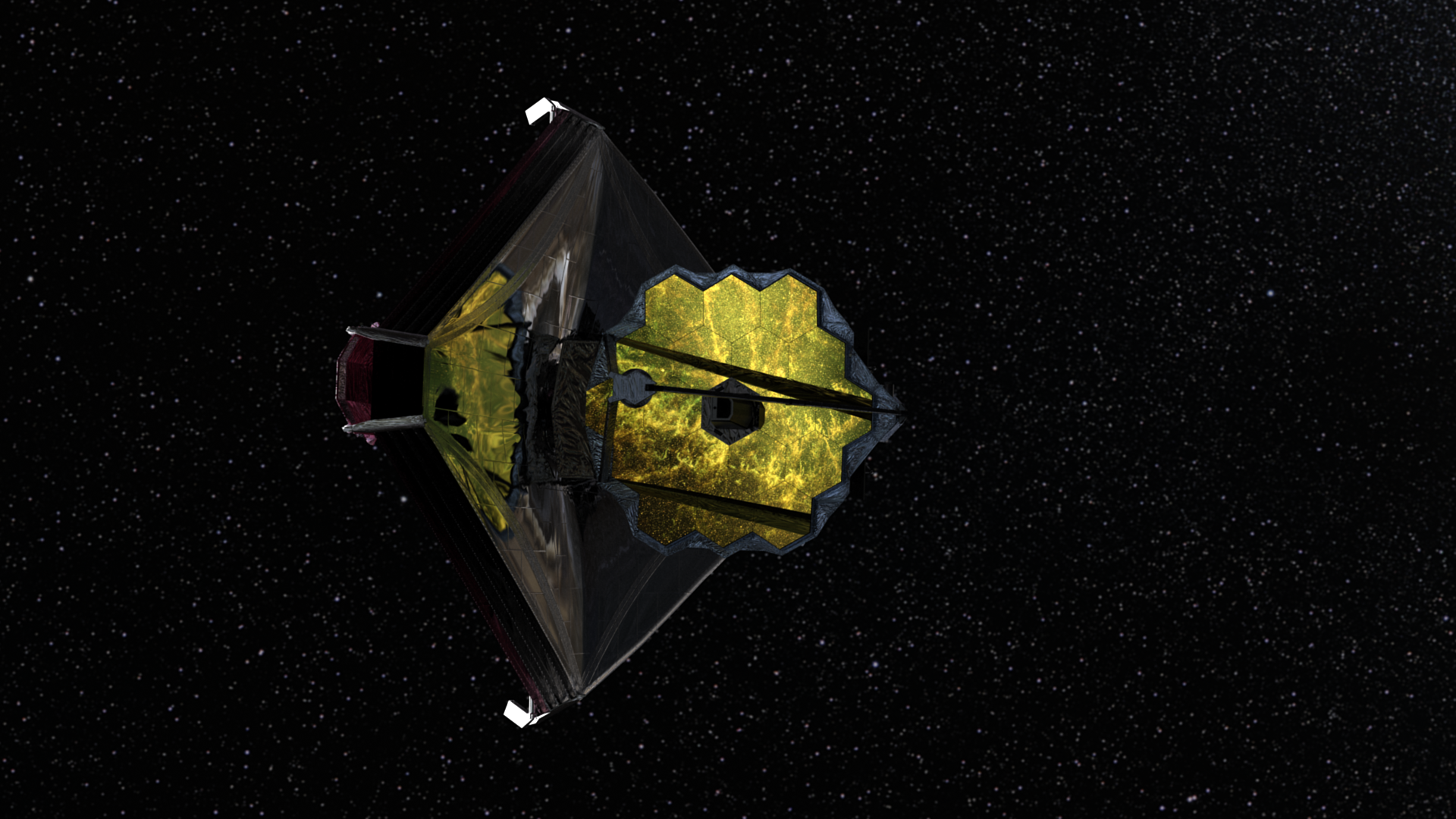

Subaperture Stitching Interferometry

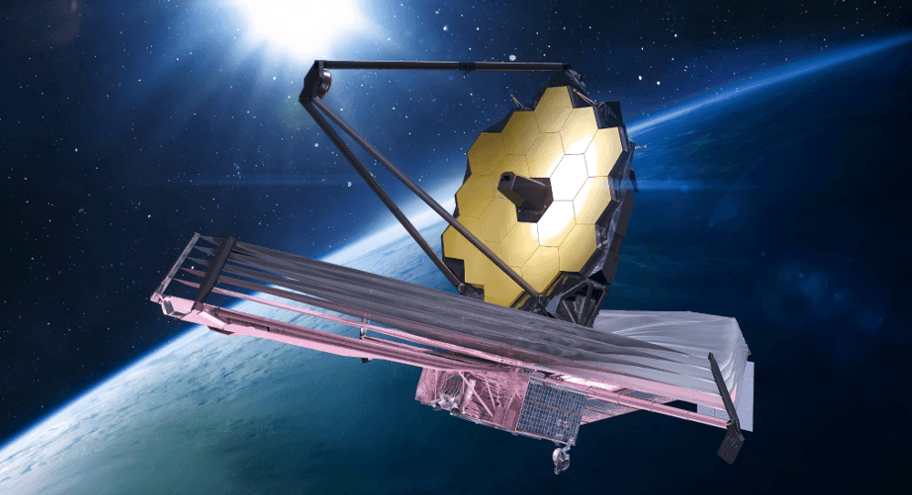

James Webb Space Telescope

NASA’s advanced optical measurement technique now enhances precision in various industries. To fabricate the James Webb Space Telescope’s large atmospheric mirrors, NASA collaborated with QED Technologies to develop subaperture stitching interferometry. This method measures sections of an optical surface and “stitches” them together for a complete, precise profile. The resulting tools, like the Aspheric Stitching Interferometer, have streamlined the production of high-precision optics in fields ranging from astronomy to semiconductor manufacturing.

Dynamic Interferometry

James Webb Space Telescope

NASA’s vibration-resistant optical measurement technology now enhances precision in various industries. To test the James Webb Space Telescope’s large mirrors under cryogenic and vacuum conditions, NASA collaborated with 4D Technology Corporation to develop dynamic interferometry. This innovation allows rapid, accurate optical measurements even in environments with vibration and air turbulence. The resulting PhaseCam interferometers are now used in aerospace, semiconductor, and medical industries for high-precision surface measurements.

Vibration Testing Systems

James Webb Space Telescope

NASA’s advanced vibration testing technology now ensures product durability across various industries. To guarantee the James Webb Space Telescope could withstand the rigors of launch, NASA collaborated with Team Corporation to develop specialized vibration tables capable of simulating intense launch conditions. These systems, featuring precise control and “soft stop” mechanisms, have since been adopted by aerospace, automotive, and defense industries to test the resilience of their products under extreme conditions.

Multi-Wavelength Interferometry

James Webb Space Telescope

NASA’s development of multi-wavelength interferometry for the James Webb Space Telescope now enhances precision measurements across various industries. To ensure Webb’s segmented mirrors met exacting standards, NASA collaborated with 4D Technology to develop a novel multi-wavelength interferometry technique. This method allows for highly precise, vibration-immune measurements of large optical components. Today, this technology is utilized in manufacturing lenses for virtual reality headsets, high-end cameras, contact lenses, advanced semiconductors, and in inspecting aircraft engine components.

Vibration Isolator Technology

James Webb Space Telescope

NASA’s development of advanced vibration isolators ensures stability for sensitive instruments, benefiting various industries. To test the James Webb Space Telescope’s delicate optics without interference from ground vibrations, NASA collaborated with Minus K Technology to develop vibration isolators capable of operating in high-vacuum environments. These isolators, which function without air or electricity, use negative stiffness mechanisms to provide exceptional stability. The technology has since been adopted in semiconductor manufacturing, microscopy, and defense applications requiring precise vibration control.

Enhanced SpaceWire Microchip

James Webb Space Telescope (enhanced ESA technology)

A communication chip originally developed for space missions, now enhanced by NASA, is making high-speed systems on Earth faster and more reliable. Originally developed by ESA (European Space Agency), SpaceWire was enhanced by NASA’s Goddard Space Flight Center to meet the demanding needs of missions like the James Webb Space Telescope. Engineers worked with BAE Systems to create a compact chip that handles communication, processing, and data routing all in one. The result is a faster, more reliable system now used in satellites, defense tech, and complex electronics across industries.

Wavefront Sensing and Control

James Webb Space Telescope

Eye surgery got a boost from mirror alignment in space. The same precision technology used to align the James Webb Space Telescope’s mirrors is now used in adaptive optics and LASIK eye surgery, allowing for finer corrections and more accurate vision enhancements.

Current Sensor Technology

Space Shuttle and Hubble Space Telescope

NASA’s development of noninvasive current sensors for space missions now enhances power monitoring across various industries. To ensure reliable power management in the Space Shuttle’s fly-by-wire systems and the Hubble Space Telescope’s solar-powered operations, NASA collaborated with American Aerospace Controls to develop advanced, noninvasive current sensors. These sensors, capable of precise measurements without direct contact, have since been adopted for use in aerospace, defense, and industrial applications, providing critical power flow monitoring in challenging environments.

Learn More