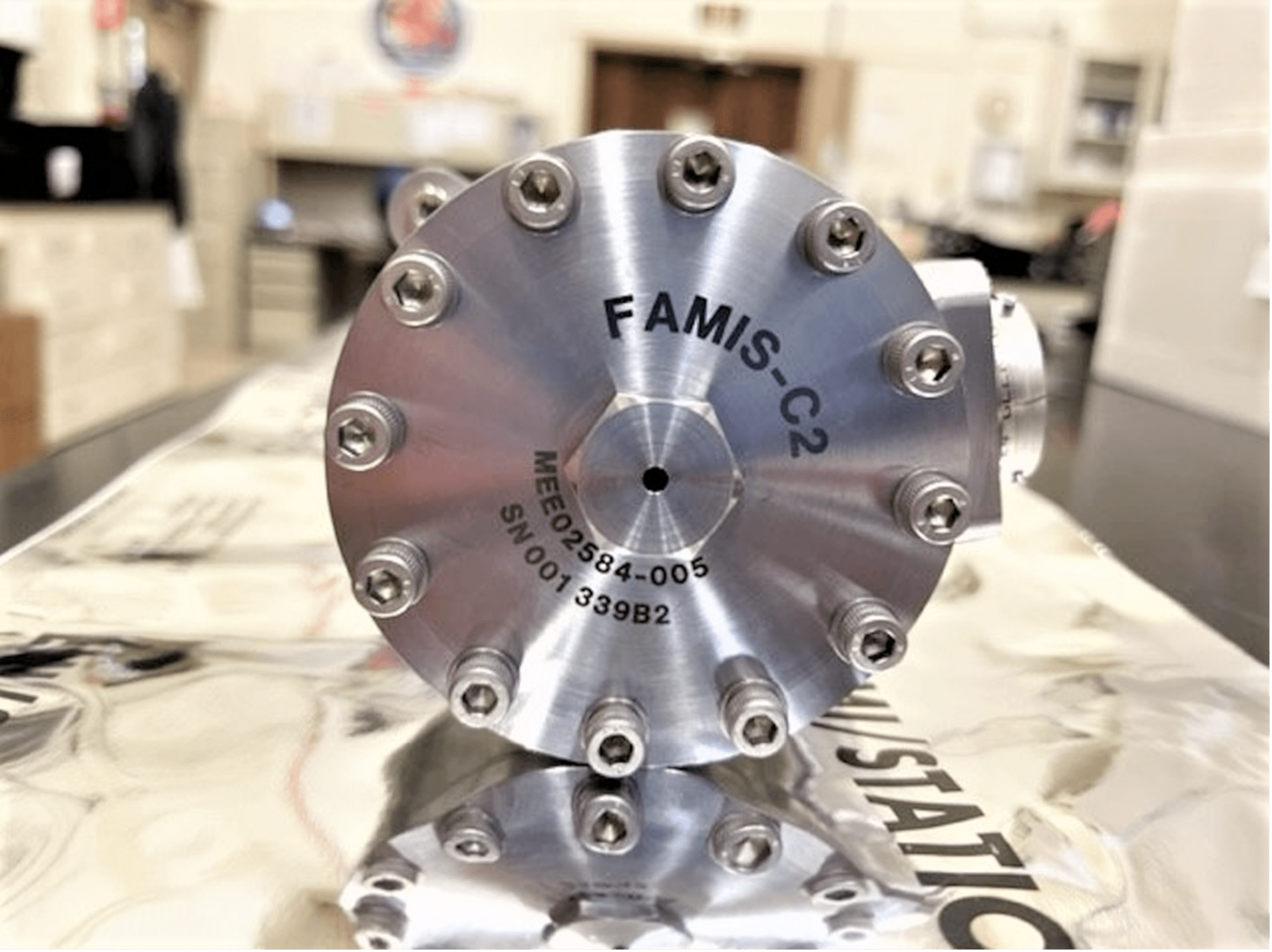

Fabrication of Amorphous Metals in Space (FAMIS)

Science Objectives

Fabrication of Amorphous Metals in Space (MSL SCA-FAMIS) studies the microstructure of composites of bulk metallic glass (BMG) and tungsten spheres processed in microgravity. BMGs, also known as amorphous metals, have excellent mechanical properties such as wear resistance. Forming composites with tungsten and BMGs could create a new class of high-performance alloys and coatings, but the vast density difference between the two makes this challenging in Earth’s gravity. Results could support development of new-generation elements for gears and coatings for applications in space and on Earth.

Status

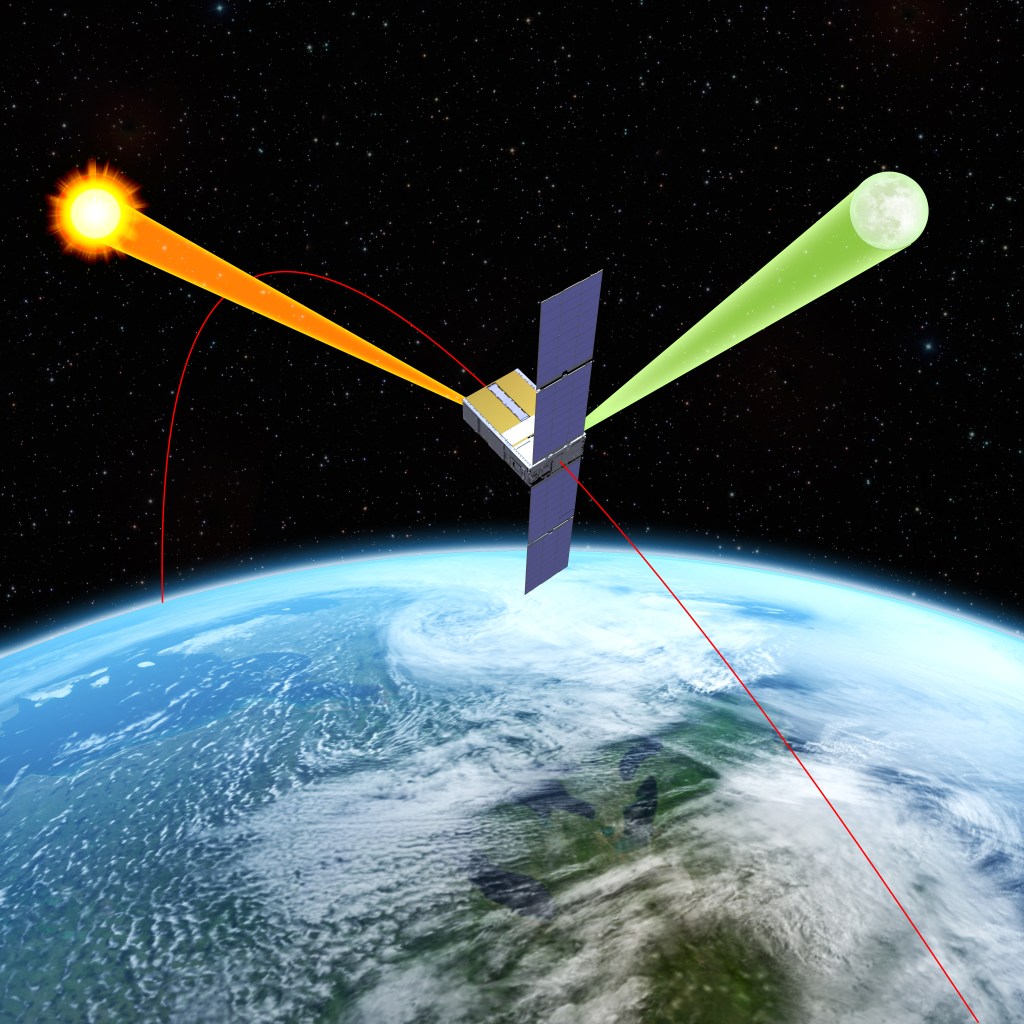

Delivery to the International Space Station via the SpaceX-26 Commercial Resupply Service mission.

Experiment Description

The goal of the Fabrication of Amorphous Metals in Space (MSL SCA-FAMIS) investigation is to perform semi-solid holds of two glass-forming alloys based in Zirconium-Niobium-Copper-Nickel-Aluminum (ZrNbCuNiAl) and Copper-Zirconium-Aluminum-Cobalt (CuZrAlCo) reinforced with tungsten spheres. The main scientific objective is to study the diffusion and reprecipitation of tungsten-based phases in the glass-forming alloys in the presence and absence of gravity-driven sedimentation. The samples are processed in the Low Gradient Furnace installed in the Materials Science Laboratory (MSL) inside the Materials Science Research Rack (MSRR) on the International Space Station (ISS).

Space Applications

This investigation could lead to development of new classes of metal alloys for gears, bearings, wear-resistant coatings, and other elements for spacecraft and robots, supporting future space exploration missions.

Earth Applications

Results could provide new metal alloys with improved performance for structural applications such as gears and coatings on Earth.